ASTM A335 P9 Studded Pipe

What is ASTM A335 P9 studded pipe?

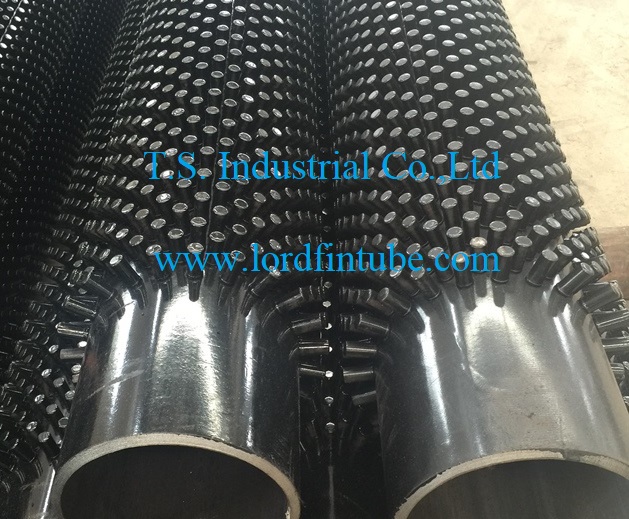

ASTM A335 P9 studded pipes are crafted from seamless ferritic alloy steel and are equipped with small metal studs protruding from their outer surface. These studs are strategically placed to increase the surface area of the pipe, facilitating improved heat transfer efficiency in applications such as heat exchangers, boilers, and other thermal systems.

ASTM A335 P9 is a specification for seamless ferritic alloy-steel pipe intended for high-temperature service. It is similar to ASTM A335 P22 but has a different alloy composition, primarily consisting of chromium and molybdenum.

A studded pipe refers to a pipe that has studs or pins attached to its outer surface. These studs are typically made of carbon steel or stainless steel and are welded onto the pipe. Studded pipes are used in applications where enhanced heat transfer or improved mechanical strength is required.

When ASTM A335 P9 is specified as a studded pipe, it means that the seamless ferritic alloy-steel pipe is manufactured according to the ASTM A335 P9 specification and has studs attached to its outer surface.

ASTM A335 P9 Pipe Chemical Composition (Percentage)

|

Element |

Composition Range (%) |

|

Carbon (C) |

0.05 - 0.15 |

|

Manganese (Mn) |

0.30 - 0.60 |

|

Phosphorus (P) |

0.025 max |

|

Sulfur (S) |

0.025 max |

|

Silicon (Si) |

0.50 - 1.00 |

|

Chromium (Cr) |

8.00 - 10.00 |

|

Molybdenum (Mo) |

0.90 - 1.10 |

ASTM A335 P9 Pipe Mechanical Properties

|

Property |

Minimum Value (SI Units) |

Minimum Value (Imperial Units) |

|

Tensile Strength, min |

415 MPa |

60,200 psi |

|

Yield Strength, min |

205 MPa |

29,750 psi |

|

Elongation, min |

30% |

- |

ASTM A335 P9 studded pipe advantages:

1. High-temperature capability: ASTM A335 P9 is designed to withstand high temperatures up to 600°C (1100°F). It is suitable for applications where elevated temperatures and thermal stresses are present.

2. Corrosion resistance: The alloy composition of ASTM A335 P9, which includes chromium and molybdenum, provides good resistance to corrosion and oxidation. This makes it suitable for use in environments with corrosive substances or high-temperature gases.

3. Enhanced heat transfer: The studs attached to the outer surface of the pipe increase the surface area, improving heat transfer efficiency. This can be beneficial in applications where heat recovery or efficient heat exchange is required.

4. Mechanical strength: ASTM A335 P9 has excellent mechanical properties, including high tensile strength and toughness. When combined with the studded pipe construction, it provides enhanced mechanical strength and durability.

5. Wide application range: ASTM A335 P9 studded pipes find applications in various industries, including petrochemical, chemical, power generation, and heat exchangers. They are commonly used in heat recovery steam generators (HRSGs), boilers, furnaces, and other high-temperature environments.

ASTM A335 P9 studded pipe typcial size:

|

ASTM A335 P9 Studded Pipe |

||||

|

Base Tube Material |

Fin Material |

Tube Length (mm) |

Fin length (mm) |

Fin Tube Quantity (Pc) |

|

ASTM A335 P9 |

SS409 |

5200 |

9044 |

72 |

|

Base Tube O.D |

Base Tube Thickness |

Stud Dia (mm) |

Stud Height (mm) |

Stud Pitch |

|

4” |

Sch40 |

12.7 |

25.4 |

18 per plain/63 PPM |

|

ASTM A335 P9 is a specification for seamless ferritic alloy-steel pipe intended for high-temperature service. It is commonly used in industries such as power generation, petrochemical, and refineries, where elevated temperatures and pressure conditions are present. |

||||

ASTM A335 P9 studded pipe is essential to consider the specific requirements of the application, including temperature, pressure, corrosion potential, and mechanical stress. Consulting with a qualified engineer or materials specialist is recommended to ensure the suitability and optimal performance of the pipe for the intended use.

ASTM A335 P9 Studded Pipe

请输入搜索关键字

确定