N Type Fin Tube|Low Finned Tube

N type fin tube also called low finned tube. The fins are rolled out of the wall of the plain tube. Tube and fin are consisting of one piece. N Type Fin Tube|Low Finned Tube suitable for heat exchangers applied mostly in LNG plants, Chemical & Petrochemical plants, Refineries, Power plants, Renewable energy plants, Naval & Marine plants. Low fins are obtained integrally from tube wall thickness by a cold forming process on the external surface. Fins increase considerably the thermo-exchanging efficiency of the tube.

Advantages: Excellent heattransfer, good bending properties, wide range of material can be used.

N Type Fin Tube Materials:

N Type Fin Tube Materials:

Carbon Steel, Low Alloy Steel,Stainless Steel, Nickel, Nickel-Copper, Nickel-Chrom-Iron, Copper Alloy, Aluminium Alloys, Titanium

N Type Fin Tube Fields of application:

Chemical-, Petrochemical- and Petroleum Industries. Used in condensers, oilcoolers, waterheaters, heatexchangers, evaporators and heat-recoverers.

N Type Fin Tube Manufacturing process:

The fins are rolled out of the wall of the plain tube by use of a pass roller. Tube and fin consist of same piece.

N Type Fin Tube Advantages

Economical solution of heatexchange problems of media with different heat conduction abilities or different current conditions. High chemical-, thermal- and mechanical resistance, suitable for rough working conditions.

N Type Fin Tube Applications: Low-Fin Tubes are used in shell and tube type heat exchangers to improve energy efficiency in refining, petrochemical, LNG, power generation, refrigeration, heating and air conditioning plants world-wide.

N Type Fin Tube Benefits: Increased surface area for heat transfer, smaller heat exchanger, less number of heat exchangers, reduced equipment and installation cost, debottlenecking existing heat exchangers, upgrading to corrosion resistant alloys without sacrificing heat transfer efficiency, and reduced fouling (in some cases).

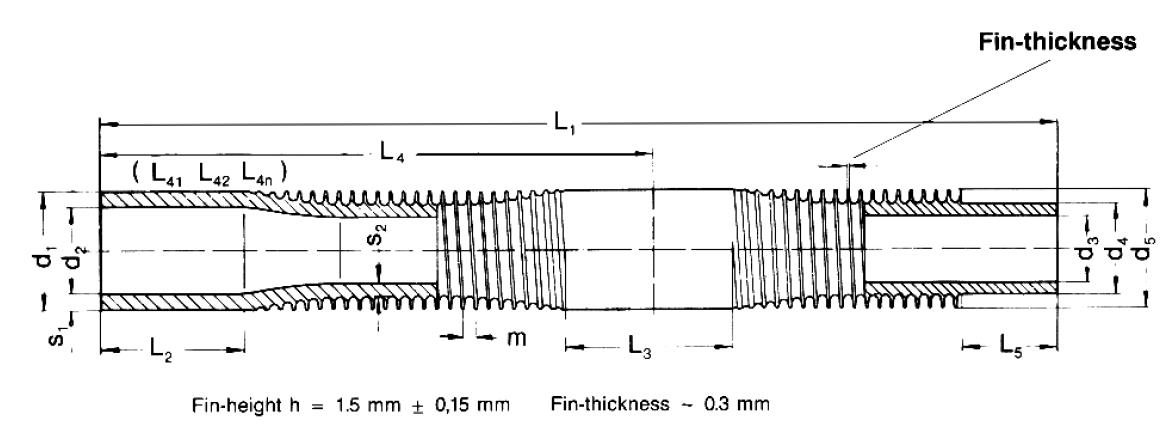

In order to forward you a promt offer we would be pleased to receive you detailed enquiry containing:

• Base tube material and quantity

• Base tube size

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

(nessesary to roll or weld the tubes into tubeplate or assembly)

N Type Fin Tube|Low Finned Tube