What is heat exchanger tube sheet?

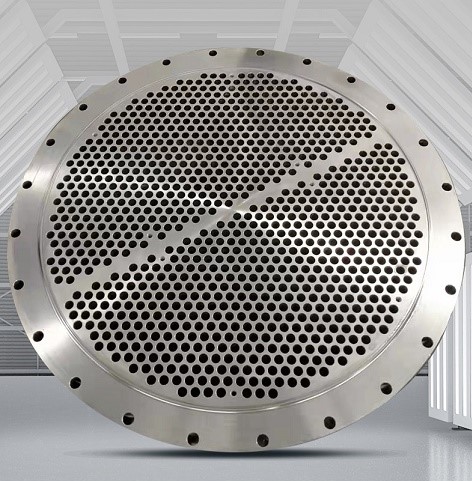

A tube sheet is a plate, sheet, or bulkhead which is perforated with a pattern of holes designed to accept pipes or tubes. These sheets are used to support and isolate tubes in heat exchangers and boilers or to support filter elements. Depending on the application, a tube sheet may be made of various metals or of resin composites or plastic. A sheet tube may be covered in a cladding material which serves as a corrosion barrier and insulator and may also be fitted with a galvanic anode. Tube sheets may be used in pairs in heat exchange applications or singularly when supporting elements in a filter.

Perhaps the best known use of tube sheets are as supporting elements in heat exchangers and boilers. These devices consist of a dense arrangement of thin walled tubes situated inside an enclosed, tubular shell. Tubes are supported on either end by sheets which are drilled in a predetermined pattern to allow the tube ends to pass through the sheet. The ends of the tubes which penetrate the tube sheet are expanded to lock them in place and form a seal.

The tube arrangement forms a contained unit between the tube sheets. The tube sheets are then bolted to flanges inside the shell. The shell extends beyond each tube sheet and is sealed, thereby forming two closed chambers on the non-tube ends of the tube sheets. This creates an arrangement where the exchanger consists of two separate end chambers joined by tubes which pass through an isolated space between the tube sheets. Heated fluid is then passed from one end chamber to the other through the tubes where cold fluid in the cavity between the tube sheets absorbs the heat energy.

The design of tube sheets is a fairly precise and complex process; the exact number of tubes needs to be established and a pattern of holes calculated to spreads them evenly over the tube sheet surface. Large exchangers may have several thousand tubes running through them arranged into precisely calculated groups or bundles. Sheet design and production is largely automated these days with computer-aided design (CAD) software performing the calculations and the tube sheet drilling done on computer numerical control (CNC) machines.

The tube sheets used in heat exchangers and boilers are often clad with an insulating layer which also serves to protect against corrosion. To further protect the tube sheet from rust, a sacrificial or galvanic anode may also be attached to the surface of the sheet. Tube sheets are also used on cartridge-type filter devices to support the individual filter elements. They are similar in design to the high heat boiler varieties except they are typically made of resin composites or plastic and are generally used as single units. There are usually fewer tubes involved in a filter application although the tube sheet design still has to be carefully calculated to ensure optimal performance.

The Fixed Tubesheet design consists of two stationary tubesheets attached to the shell. The bundle of straight tubes are connected between the tubesheets and contain baffles to direct the flow around the tubes in order to generate the required heat transfer. A head assembly is attached to each tubesheet.

The U-tube design consists of straight length tubes bent into a U-shape with both ends terminating at the tubesheet. The tube bundle is fitted with supports or flow baffles. The tubesheet/tube bundle is placed in the shell and bolted between the head flange and body flange. A head assembly is required to direct the fluid into and out of the tube bundle. This configuration allows for the entire tube bundle to be removable.

A Floating Tubesheet design is similar to the Fixed Tubesheet design except one tubesheet is allowed to move axially within the shell while the other tubesheet is fixed.

One of the most common heat exchangers in service within industrial process applications is the “Tube Sheet Heat Exchangers”. They are available in many shapes, sizes and have been used in industry for over 150 years. In this exchanger group are various sub design types: Fixed, U-tube and Floating tubes heet. Variations of all can be denoted as type “E”, “F”, “G”, “H”, “J”, “K” or “X”. The main applications are where high pressure/temperatures are key considerations. Loosely, general designs consist of the/an outer shell in which resides a tube bundle (these can be configured as finned, plain etc) sealed at each end by a tube sheet which isolates the tubes and the outer shell.

Tube Sheet Heat Exchangers have the capability to transfer large amounts of heat at low(er) costs. This, in principle, down to both design simplicity and effectiveness – large tube surface for reduced weight, volume of liquid and importantly floor space.

Whilst there is a wide variety to choose from there are certain key components similar in all. Tube sheets have tubes attached to them within the body or “shell” of the heat exchanger. The tubes allow the movement of a given medium (gas/fluid) through the shell chamber stopping it mixing with a second fluid medium that lies outside these tubes. As long as there is a temperature difference between these, in effect, the two flow past one another exchanging heat without ever mixing. Tube sheets can be fixed or floating dependent on the application the heat exchanger is designed for.

Tube sheets are a critical component of the final design. There are a multitude of materials they can be manufactured from. Material selection is made after careful consideration as it is in contact with both fluids. It must therefore have the necessary corrosion resistance, electromechanical and metallurgical properties associated for its given working environment.

The tube sheets themselves contain holes drilled into them. This, in a given, very specific design configuration, at very precise locations with critical tolerances. The amounts of holes can range from a few to thousands. These pattern or “pitch” holes are relative to each other tube sheet within the shell. This pitch changes tube distance, angle and flow direction. These parameters have been varied to maximize the heat transfer effectiveness.

Tube Sheet Heat Exchangers of the big advantages of using a shell and tube heat exchanger is that they are often easy to service, particularly with models where a floating tube bundle where the tube plates are not welded to the outer shell is available. Fixed Tube Sheet Heat Exchangers used on fixed tube sheet heat exchangers.

Tube Sheet Heat Exchangers the right choice of materials they can also be used to cool or heat other mediums, such as swimming pool water or charge air. Fixed Tube Sheet Heat Exchangers ideal cooling solution for a wide variety of applications. One of the most common applications is the cooling of hydraulic fluid and oil in engines, transmissions and hydraulic power packs.

Heat exchanger tube sheet usage

The heat exchanger tube sheet serves several important functions.

First, it holds the tubes in place and provides a secure mounting point for them. This helps to ensure that the tubes do not shift or move during operation, which could cause damage or leaks in the heat exchanger.

Second, the tube sheet provides a sealing surface for the fluid being exchanged. This helps to prevent leaks between the tubes and the shell, which could result in a loss of efficiency or even damage to the heat exchanger.

Finally, the tube sheet is designed to withstand the pressure and temperature of the fluids being exchanged. This is critical for ensuring the safety and reliability of the heat exchanger, as well as its overall performance.

In some cases, the tube sheet may also be designed to allow for easy maintenance and repair. For example, it may be designed to be easily removed and replaced if necessary, or to allow for easy access to the tubes for cleaning or inspection.

Overall, the heat exchanger tube sheet is a critical component of shell-and-tube heat exchangers, and its proper design, fabrication, and maintenance are essential for ensuring the safe and efficient operation of these devices.

Heat exchanger tube sheet material used

Heat exchanger tube sheets are typically made of high-strength materials that can withstand the pressure and temperature of the fluids being exchanged. Common materials used for tube sheets include carbon steel, stainless steel, titanium, and nickel alloys.

1. Carbon steel is a popular choice for tube sheets due to its strength, durability, and cost-effectiveness. However, it is susceptible to corrosion and may require protective coatings or other measures to prevent corrosion.

2. Stainless steel is another popular choice for tube sheets, particularly in applications where corrosion resistance is a concern. It is highly resistant to corrosion and can withstand high temperatures and pressures.

3. Titanium is often used in applications where weight and corrosion resistance are critical factors. It is highly resistant to corrosion and is lightweight, making it ideal for use in heat exchangers in the aerospace and marine industries.

4. Nickel alloys, such as Inconel and Monel, are also commonly used for tube sheets in high-temperature and corrosive environments. These alloys are highly resistant to corrosion and can withstand extreme temperatures and pressures.

In general, the choice of material for a heat exchanger tube sheet will depend on a variety of factors, including the specific application, the operating conditions, and the cost and availability of materials.

Heat exchanger tube sheet inspection standard

The inspection of heat exchanger tube sheets is an important part of ensuring the safe and efficient operation of the heat exchanger. There are several standards and guidelines that are used to govern the inspection of heat exchanger tube sheets, including:

1. ASME Boiler and Pressure Vessel Code - Section VIII, Division 1: This code provides guidelines for the design, fabrication, and inspection of pressure vessels, including heat exchangers. It specifies the requirements for inspecting tube sheets, including visual inspections, non-destructive testing, and dimensional measurements.

2. API 570 - Piping Inspection Code: This standard provides guidelines for the inspection, repair, and alteration of in-service piping systems, including heat exchanger tube sheets. It includes guidelines for visual inspections, ultrasonic testing, radiographic testing, and other non-destructive testing methods.

3. ASTM E446 - Standard Reference Radiographs for Steel Castings Up to 2 in. (50.8 mm) in Thickness: This standard provides reference radiographs for use in evaluating the quality of steel castings, including tube sheets. It includes radiographs for various levels of quality, from acceptable to rejectable.

4. NACE MR0175/ISO 15156 - Petroleum, petrochemical and natural gas industries — Materials for use in H2S-containing environments in oil and gas production: This standard provides guidelines for materials selection, manufacturing, and inspection in environments containing hydrogen sulfide (H2S), which can cause corrosion and other damage to heat exchanger tube sheets.

Overall, the inspection of heat exchanger tube sheets should be performed by qualified personnel using appropriate testing methods and equipment. The specific inspection requirements will depend on the specific heat exchanger design, operating conditions, and applicable codes and standards.

Heat exchanger tube sheet size and shape

Heat exchanger tube sheets come in a variety of sizes and shapes, depending on the specific heat exchanger design and application. The size and shape of the tube sheet will typically be determined by the number and size of the tubes, as well as the dimensions of the heat exchanger shell.

Tube sheets can range in size from a few inches in diameter for smaller heat exchangers to several feet in diameter for larger industrial heat exchangers. The thickness of the tube sheet will depend on the pressure and temperature of the fluids being exchanged, as well as the material used.

In terms of shape, tube sheets are typically circular or rectangular, with holes drilled or punched to accommodate the tubes. The pattern and spacing of the tubes will depend on the specific heat exchanger design and application.

Some tube sheets may also have additional features, such as grooves or indentations to improve the flow of fluids, or flanges to facilitate connections to other parts of the heat exchanger.

Overall, the size and shape of the heat exchanger tube sheet will be determined by the specific application and operating conditions, and will be designed to optimize the performance and efficiency of the heat exchanger.

A heat exchanger tube sheet is a component used in shell-and-tube heat exchangers that holds the tubes in place and provides a sealing surface for the fluid. It is typically made of a high-strength material, such as stainless steel or carbon steel, and is designed to withstand the pressure and temperature of the fluids being exchanged.

From a design perspective, the tube sheet must be designed to withstand the mechanical loads imposed by the tubes, as well as the pressure and temperature of the fluids. It is typically designed using finite element analysis (FEA) to ensure that it can withstand these loads and to optimize its performance.

In terms of fabrication, the tube sheet is typically manufactured using a variety of techniques, including drilling, milling, and punching. The holes for the tubes are typically drilled or punched, and the tube sheet is then machined to the desired shape and size.

During operation, the tube sheet must be regularly inspected to ensure that it remains in good condition and that there are no leaks or other issues. If problems are detected, the tube sheet may need to be repaired or replaced.

Overall, the tube sheet is a critical component of shell-and-tube heat exchangers, and its design, fabrication, and maintenance are all important aspects of ensuring that the heat exchanger operates effectively and efficiently.

Heat Exchanger Tube Sheet, Tube Sheet Heat Exchangers,Tube Plate