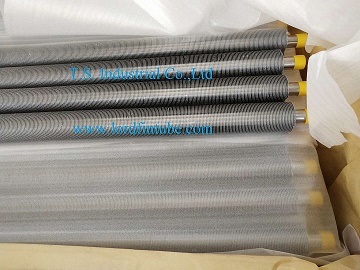

Extruded stainless steel heat exchanger fin tubes

What is extruded seamless stainless steel heat exchanger fin tubes?

Extruded seamless stainless steel heat exchanger fin tubes are specialized heat transfer components used in heat exchangers. They consist of a seamless stainless steel tube with integral fins that are extruded from the tube itself or extruded aluminum fins on tube out surface. The fins are continuous and extend outward from the tube surface, increasing the surface area for efficient heat transfer.

Why choose Extruded seamless stainless steel heat exchanger fin tubes?

There are several reasons to choose extruded seamless stainless steel heat exchanger fin tubes:

1. Enhanced heat transfer efficiency: The integral fins increase the surface area available for heat transfer, resulting in improved heat exchange performance and efficiency.

2. Corrosion resistance: Stainless steel is known for its excellent corrosion resistance properties, making these fin tubes suitable for applications involving corrosive fluids or environments.

3. High strength and durability: The seamless stainless steel construction provides mechanical strength and durability, ensuring long-term performance in demanding operating conditions.

4. Compact design: The extruded fin design allows for a higher fin density within a limited space, enabling more effective heat transfer in compact heat exchanger designs.

Whats the main application of Extruded seamless stainless steel heat exchanger fin tubes?

Extruded seamless stainless steel heat exchanger fin tubes find applications in various industries, including:

- Power generation: Used in power plants for heat transfer in boilers, condensers, and other heat recovery systems.

- Petrochemical and chemical processing: Utilized in heat exchangers for efficient heat transfer in refining, chemical processing, and other industrial processes.

- HVAC (Heating, Ventilation, and Air Conditioning): Applied in air conditioning systems, chillers, and air-cooled heat exchangers for effective temperature regulation.

How to produce extruded seamless stainless steel heat exchanger fin tubes?

The production process of extruded seamless stainless steel heat exchanger fin tubes involves the following steps:

1. Tube preparation: Seamless stainless steel tubes are selected based on the desired specifications, including diameter, thickness, and material grade.

2. Fin extrusion: The selected tubes are placed in a specialized extrusion machine. The machine applies pressure to force the material of the tube to flow through shaped dies, forming the integral fins on the outer surface of the tube.

3. Fin profile and dimensions: The shape, height, and spacing of the fins are determined by the design of the extrusion dies. These parameters can be customized based on the specific heat transfer requirements.

4. Finishing and inspection: After extrusion, the finned tubes undergo finishing processes such as cutting to the desired length, deburring, and cleaning. They are then inspected for quality assurance, including dimensional accuracy and fin integrity.

Extruded seamless stainless steel heat exchanger fin tubes

请输入搜索关键字

确定