What is pitted tube?

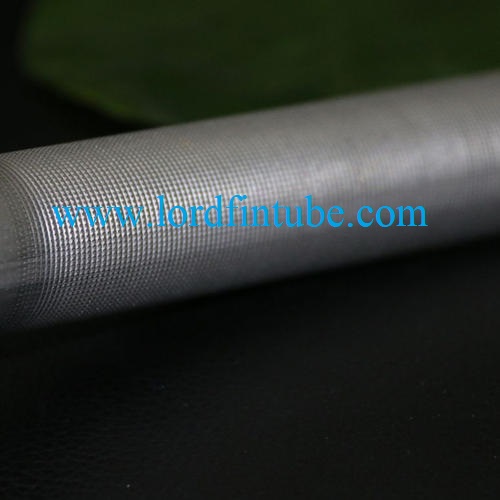

The pitted tube means that there are several groups of spiral grooves on the outer wall of the pipe body. The spiral grooves cover the outer wall of the whole pipe body. The spiral grooves are discontinuous. The spiral grooves are divided into two groups. The two groups of spiral grooves are staggered. Four adjacent spiral grooves extrude the outer wall of the pipe body enclosed by the spiral grooves into a bulge. The cross section of the spiral groove of the pitted pipe is inverted triangle. The pitted surface pipe increases the heat exchange efficiency of the pipe, reduces the amount of pipe, has low production cost, and can be used in long-distance heat exchange places.

High efficiency pitted tube refers to make enhancement to the ordinary inside and outside smooth surface of the heat exchange tube, so that the overall heat exchange effect can be significantly improved.

High efficiency pitted tube Application

Mainly used in lithium bromide air conditioning (non-electric air conditioning) and other industries. Pitched tube is used in various occasions of evaporation heat exchange.

High efficiency pitted pipe refers to make enhancement to the ordinary inside and outside smooth surface of the heat exchange tube, so that the overall heat exchange effect can be significantly improved.

Strengthening form : to the internal and external surfaces of the heat exchange tube, through extrusion and rolling, processing a variety of shapes (spiral squamous tooth, bump and groove, etc.), to change the constant liquid flow field distribution, formation of turbulent flow, or to improve the effect of convection. Meantime through the physical form processing, extending internal and external surface to increase the heat transfer area of the internal and external surface, to improve the heat transfer coefficient of heat exchange tube and improve the overall heat transfer effect.

Pitted tube main types:

We provide 3 types of below:

1. The outer wall pattern, the inner wall is smooth.

2. Inner and outer wall pattern.

3. High heat pipe with smooth inner wall pattern and outer wall.

Pitted tube main material grade:

The material grade for pitted tubes can vary depending on the specific application and requirements. Common materials used for pitted tubes include stainless steels such as 304, 316, and duplex stainless steels like 2205. These materials offer good corrosion resistance and mechanical properties suitable for various industrial applications, including heat exchangers, condensers, and other process equipment. Additionally, nickel alloys like Inconel and Hastelloy are also used in more demanding environments where corrosion resistance is critical. The selection of the material grade depends on factors such as operating conditions, fluid composition, temperature, and pressure.

Pitted Tube |