What is tube bundle?

A tube bundle is a collection of tubes that are arranged in a circular or rectangular pattern and secured at each end by tube sheets. Tube bundles are used in various types of heat exchangers, such as shell and tube heat exchangers and air-cooled heat exchangers. Both straight tube bundle and U bend air-cooled bundles , which can be replaced without alteration of the heat exchange capacities and are fully adaptable to existing piping and structure.

1. The first of the most common tube bundle configurations is the straight tube type. This layout consists of straight tubes which open either end of the bundle into entry and exit chambers which form the end caps on the shell. The hot material is pumped through the bundle in a straight line from one end of the shell to the other. This arrangement is efficient, but requires considerable effort to open the shell and remove the bundle when cleaning or repairs be required. Straight tube arrangements feature lower initial installation costs.

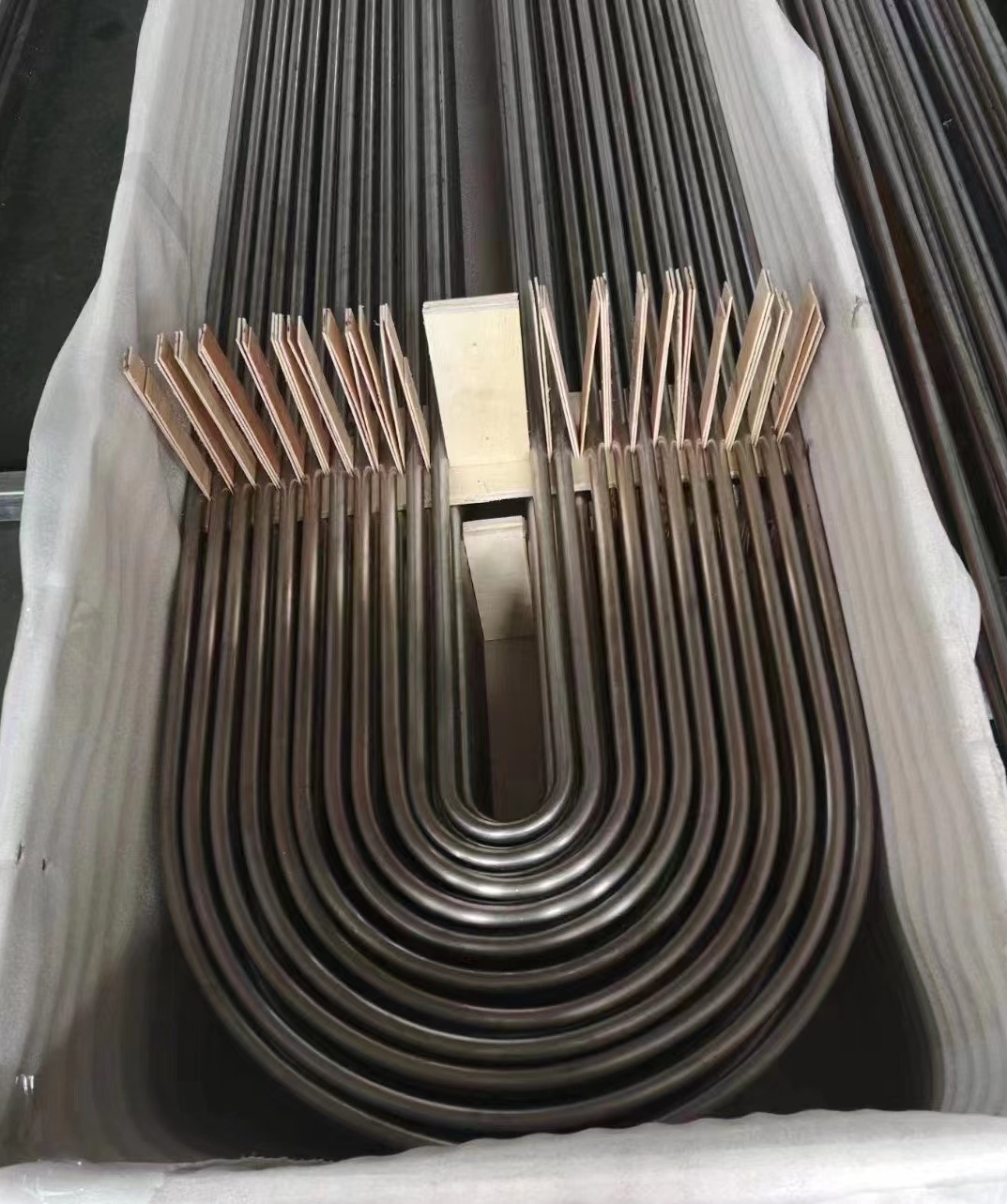

2. The second common tube bundle is the U tube bundle. This bundle variant features entry and exit points on the same side of the shell on a tube shell cap divided into two sealed chambers. The tubes leave the entry chamber and travel to the opposite end of the shell where they make a U bend and return in the opposite direction to the exit chamber. This type of layout is easier to disassemble for maintenance with the bundle typically being slid out as a modular unit. U configurations also accommodate high temperature differentials well and relieve most thermal expansion and contraction stresses in the bundle.

U tube type heat exchanger use U bend Tubes and fixed both ends on the same tube plate, each tube can be freely telescopic, so as to solve the heat compensation problem. The pipes is at least two courses, the tube can be removed,cleaned and the expanded freely. The disadvantage of the U tube heat exchanger is the inside of the pipes are difficult to be cleaned, and also difficult to replace the new pipes. Furthermore the tubes quantity arranged on the pipe plate are samll. The utility model has the advantages of simple structure, low weight and suitable for high temperature and high pressure.

Why Use a Tube Bundle?

U bend tube designs also allow for the tube bundles easily removed from the heat exchanger. This is helpful in inspection and cleaning of the shell and outside of the tube bundle.

Many people are not aware of what it is but the tube bundle is basically a group of tubes which are tied with each other by rods amidst the shell & tube heat exchangers. These bundles can in handy during the heat exchange process on a large scale. This has many high end benefits in both the short and the long run. However, individuals should be aware of what it does and does not offer in the long run. Generally, this bundle is found in this particular heat exchanger due to the fact that it contains a wide range of tubes in the first place.

1. Tube Bundle with High Heat Efficient

The heat efficiency is one of the most major reasons for actually using heat exchangers. With the help of a tube bundle, the efficiency of heat tends to increase by a long shot, which makes the overall process much more productive and fully fulfills the requirements in the overall procedure of heat transfer. In shell & tube heat exchangers, this bundle has been specifically manufactured for this very purpose, and it most definitely fulfills that in both the short as well as the long run.

2. Tube Bundle is Easy to Installation

It is much more simpler to install tube bundles than install other types tube cores. Most of the installation has to be done underground. While in some case of the shell and heat exchanger, the installation has to be done inside the shell, which is a much more congested area. The simplicity of tube bundles is that they are not twisted but are made by straight tubes, which design makes their replacement much easier.

3. How to Choose Tubing materials

Most tubing companies order a number of different materials for creating tube bundles. Manufacturers realize that different consumers of tube bundles require different types of materials for their tubes. Thus, they can choose tube bundle made up of carbon steel or stainless steel. In the case of high heat transfer, they may use copper or copper alloys.

U Tube Bundle |