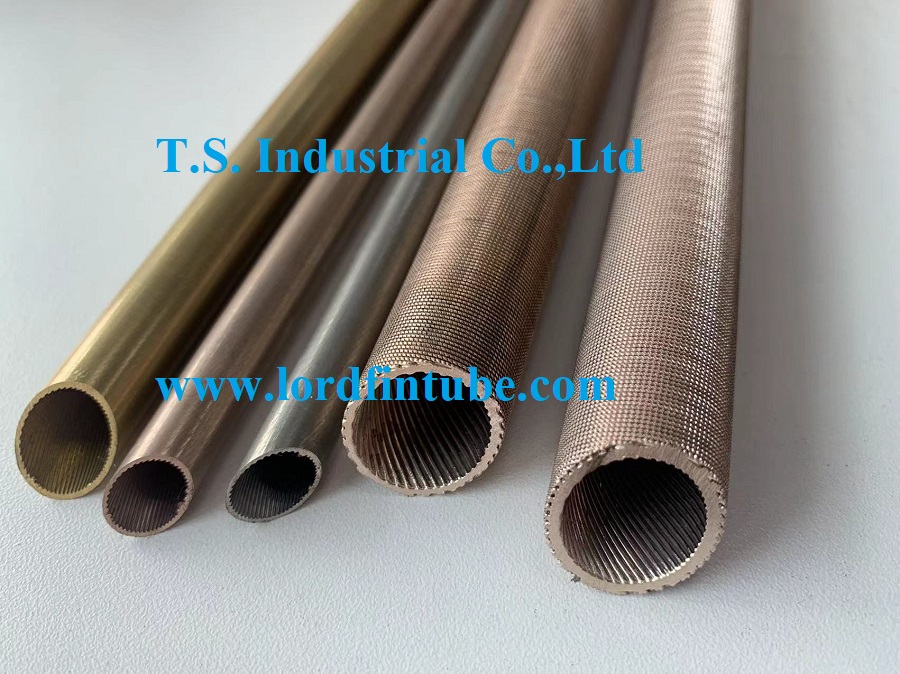

What is T-finned tube?

The T-finned tube is a type of heat transfer element that consists of a tube with integral fins in the shape of the letter "T." The fins are attached to the outer surface of the tube, extending radially outward. This design creates an extended surface area, which enhances heat transfer efficiency between the tube and the surrounding fluid or air.

The principle behind T-finned tubes is to increase the heat transfer area while maintaining a compact size. The fins on the tube serve to increase the surface area available for heat exchange, allowing for improved heat transfer rates. The T-shaped design provides additional rigidity and strength to the fins, enabling them to withstand higher pressures and resist deformation. T-finned tube or low fin tube is composed of the bare pipe through the rolling process forming an efficient heat transfer tubes. Its structure is characterized by an outer surface of the tube to form a series of spiral ring T-tunnel. When the heat medium outside the tube to form a series of cell nuclei in the tunnel, since the chamber is surrounded by a tunnel heated state, the rapid expansion of cell nuclei filled cavity, continuously heated rapidly increases the inner pressure of the bubble, the bubble from the tube surface to promote slit the rapid discharge. With larger bubbles ejected erosion force and a certain partial vacuum, so that the surrounding liquid into a lower temperature T type tunnels, forming continuous boiling. This boiling manner in unit time per unit surface area of the heat away much larger than the bare pipe, so this tube has a high boiling heat transfer capability. As long as the shell side of the medium is relatively clean, no solids, no gum, may be employed as a T-finned tube heat exchanger components, forming a T-shaped fin tube type heat pipe heat exchanger efficiency, to improve the shell-side boiling heat transfer.

T-finned tubes applications

1. Heat Exchangers: T-finned tubes are extensively used in heat exchangers for applications such as air conditioning, refrigeration, and industrial process cooling. The increased surface area provided by the fins allows for better heat transfer between the fluid inside the tube and the ambient air or another fluid flowing around the tube.

2. Boilers: T-finned tubes are utilized in boilers to enhance heat transfer efficiency. The fins help maximize the contact surface area, allowing for improved heat exchange between the combustion gases and the water or steam inside the tubes.

3. Air Coolers: T-finned tubes are employed in air coolers for various industries, including power plants, refineries, and petrochemical plants. The extended surface area provided by the fins enables efficient cooling of the process fluids or gases using ambient air.

4. Radiators: T-finned tubes are utilized in automotive radiators, where they assist in transferring heat from the engine coolant to the surrounding air. The fins increase the surface area of the tubes, enhancing the cooling efficiency of the radiator.

5. Heat Recovery Systems: T-finned tubes can be incorporated into heat recovery systems, where they help capture and transfer waste heat from industrial processes to be utilized in other applications, resulting in energy savings.

6. Evaporators and Condensers: T-finned tubes are used in evaporators and condensers of refrigeration and air conditioning systems. The increased surface area provided by the fins allows for efficient heat transfer during the phase change of the refrigerant.

By utilizing T-finned tubes in these applications, engineers can achieve improved heat transfer performance, leading to enhanced system efficiency, reduced energy consumption, and more compact designs. The specific design and configuration of T-finned tubes can be tailored to meet the requirements of the application, considering factors such as fluid characteristics, operating conditions, and space limitations.

T-finned tube or low fin tube |