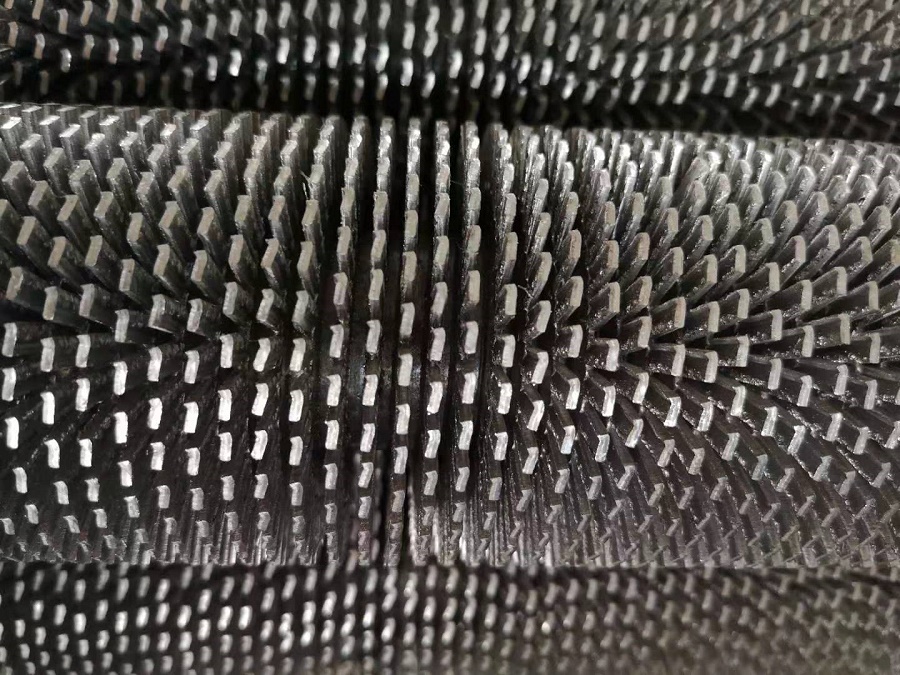

What is high frequency welding serrated finned tube?

High-frequency welding serrated finned tube is serrated the steel fin strip before high-frequency welding, and then use high-frequency current skin effect of high temperature weld serrated fin strip onto the pipe. Finned pipe welding process with a high fastness, good heat transfer efficiency. In addition fin spoiler role increase with serrated fins to improve the heat transfer efficiency and can better to prevent fouling.

High-frequency welding serrated finned tube

1. Technical description

Technical principles feed pipe from the storage system into the automatic loading rack, and then re-entering the chucking head; steel tooth system through open after a tooth, also entered the chucking head In chucking the handpiece while the strip wound pipe into the high-frequency welding, using high-frequency current skin effect and proximity effect, on the strip and steel pipe is heated until the plastic state or melt; at the same time to bring Steel certain pressure, i.e., to complete the welding. This high frequency welding is a solid-phase welding, the welding process controlled by the PLC program, this high degree of welding automation, welding fusion rate of 95%. The main technical indicators

2. Technical Specifications zigzag frequency welding spiral finned tube production line:

(1), spindle speed 700 rev / min;

(2), welded steel pipe diameter Φ 25-Φ 90mm, pipe wall thickness 2-10mm, tube length 0.5 -24mm

(3), welding fin thickness 0.8-3mm, fin spacing 4-50mm;

(4), open tooth width 4-7mm.

3. Technical indicators zigzag frequency welding spiral finned tube production line of finned tubes:

Finned pipe size deviation

(1) Foreign Economic deviation d ≦ 1.5mm

(2) tilt angle 〆 ≦ 8 °

(3) Fin Pitch deviation a. in any 10 pitches average of ≦ 0.5mm b fins deviation of less than full length ± 10 mm c deviation is less than the number of fins ± 1.5%

Welded finned tube

(1) partially unmelted weld portion is smaller than the length of the finned tube diameter, and less than 50 mm

(2) Welding Local seam unmelted quantity per meter pipe length is less.

(3) Pull-off strength ≥196MPa

(4) ≥80% fusion rate, high-frequency welding spiral finned tube production line can produce all kinds of carbon steel, low-alloy steel and stainless steel spiral wing sheet tube.

4. production lines composed of zigzag-frequency welding spiral finned tube production line consists of the following components:

(1) automatic loading frame;

(2) automatic unloading aircraft;

(3) high-frequency welding group;

(4) Frequency Welding card unit;

(5) material storage systems;

(6) the strip open tooth systems;

(7) water circulation system.

5. The entire system using the PLC system control

The implementation of product quality standards product implementation JB / T6512 standards. Quality standard name is "high frequency resistance welding spiral fin tube boiler manufacturing technology conditions"

High-frequency welding serrated finned tube |