Distinguishing between Single Metal Finned Tubes and Bimetal Finned Tubes

Single metal finned tubes and bimetal finned tubes represent two distinct variants in finned tube design, each offering distinct advantages. Known as finned tube heat pipes, they exhibit pronounced disparities in composition and performance.

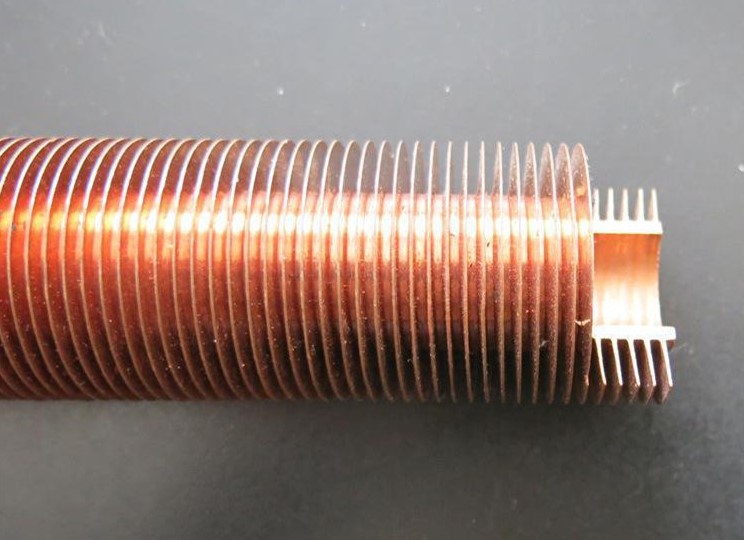

Single metal finned tubes are exclusively crafted from rolled aluminum, commonly termed as aluminum rolling finned tubes. These tubes boast remarkable non-contact thermal resistance, robust strength, high heat resistance, mechanical vibration resilience, and exceptional thermal expansion properties. Their construction significantly augments heat transfer surfaces, rendering them versatile for a myriad of applications. Moreover, single metal finned tubes can also be fabricated from rolled steel or brass. Notably, copper fin tubes, a subset of single metal finned tubes, feature low fin heights and thicknesses, typically under 32mm and ranging from 0.3mm to 4.0mm. With negligible contact thermal resistance and impressive thermal expansion characteristics, copper fin tubes find widespread utility across industries for various heating, drying, condensation, and cooling processes.

In contrast, bimetal finned tubes encompass steel-aluminum and copper-aluminum composite variants. Steel-aluminum composite fin tubes comprise steel and aluminum or stainless steel and aluminum, rolled into composite fins. Similarly, copper-aluminum composite finned tubes are formed from brass and aluminum, rolled into intricate fin configurations. These bimetal tubes offer a blend of tight coupling, minimal resistance, superior heat transfer performance, high strength, low flow loss, robust corrosion resistance, and resistance to deformation under cold conditions, resulting in extended operational lifespans.

The base materials for bimetal finned tubes vary, including copper, carbon steel, or stainless steel, with aluminum serving as the outer pipe material. Bimetal finned tubes excel in providing extensive heat transfer areas, high efficiency, durability, corrosion resistance, ease of cleaning, and prolonged lifespans, making them indispensable components in advanced heat exchanger systems.

Both single metal and bimetal finned tubes find wide-ranging applications across industries such as petroleum, chemical, metallurgy, textile, machinery, light industry, and medicine, catering to diverse needs in heating, drying, condensation, and cooling processes.

Available in a range of specifications, brass diameters typically span from Φ12 to Φ32mm, aluminum fins from Φ18 to Φ64mm, with fin thicknesses ranging from 2mm to 5mm, while offering customization options to meet specific customer requirements.

The manufacturing process ensures overall rolling fin smoothness without glitches or wrinkles, facilitating easy cleaning and preventing dirt and fouling accumulation. Additionally, the anodized surface finish enhances corrosion resistance and aesthetics, ensuring prolonged operational integrity in various environments.

Single Metal Finned Tubes |