Laser welded stainless finned tube produce by stainless steel tube and stainless fin strip. The laser welding rate can reach 100% and heat transfer capacity sharply increased.

The base tube material can be TP316L mainly, but all other in stainless steel 304, 316, 1.4404, 1.4301, and 1.5471 etc. could be done.

The fin strip material could be 304, 316,1.4301, 1.4404, and 1.4521.

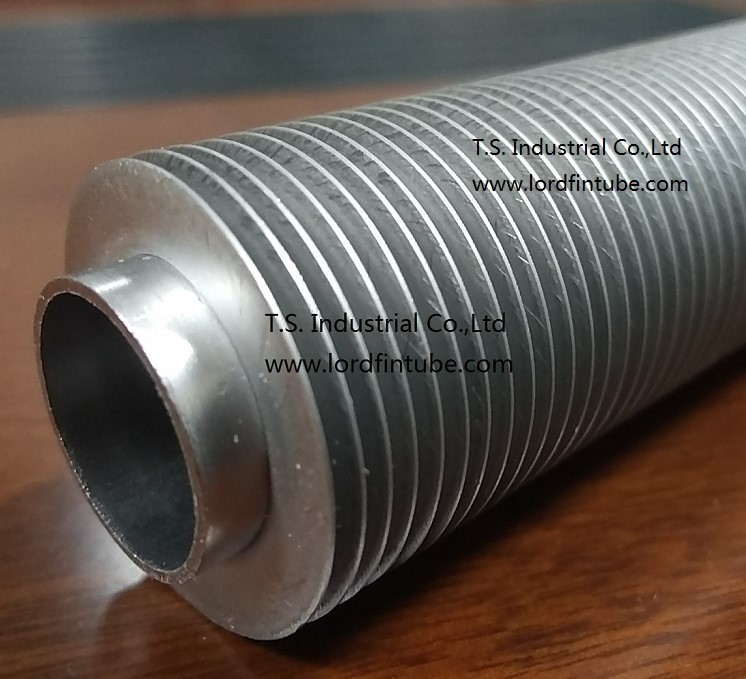

Laser welded stainless finned tube sample info: Tube is 22 x 20 mm, fin is 0,4 mm x 7 mm height, 11 fins per 1”, laser welded finned Tubes can be made in various lenghtes from 50 cm – up to > 10 meters and different diameters.

The laser welded stainless finned tube complete connection between the fins and the base tube brings about excellent heat transfer and up to 2.5 times higher thermal performance of the finned tubes.

The continuous weld prevents notch effects and v Corrosion and the formation of cracks are hence avoided also in the case of possibly oscillating finned tubes. Laser welded fins tube has highly anti corrosive proformance, suitable for heat recovery, energy savings, etc. in vine / petrol / milk / food / chemical industries.

The low base metal heating during welding and the high speed of travel of up to 20m/min. minimise the heat-affected zone in the base tube. Complete melting of the tube and a related metallurgical transformation of the parent metals are hence excluded.

Laser welded stainless finned tube description

· thin, continuous weId seam

· small heat-affected zone

· only slight discolouration weld site

· only slight microstructural change in tube and fin

· high utilization of heat for forming the seam

· increased safety because of the avoidance of crevice corrosion due to the high weld integrity between tube and fin

· no impurity of the weld seam, as the Laser-welding is carried out under a protective atmosphere

Laser welded stainless finned tube dimensions

· Tube outside diameter 8.0–50.0 mm

· Fin outside diameter 17.0 –80.0 mm

· Fin pitch 5 –13 fin/inch

· Fin height 5.0 –17 mm

· Fin thickness 0.4 – 1.0 mm

· Maximum tube lengths 12.0 m

Laser welded stainless finned tube

Laser welded stainless finned tube application

Laser welded stainless finned tube in Power Plants

· Cooling towers or cooling water recooling plants with dry, dry / wet or wet operation

· Flue gas cooling and heating in flue gas desulfurisation scrubbers (FGD) and nitrogen removing plants (DENOX)

Laser welded stainless finned tube in Chemical Industry

· Heat exchangers of all kinds for cooling and heating of liquids and gases

· Heat exchangers tor nitric acid (HNO3) plants, e.g. for the fertilizer industry

Laser welded stainless finned tube in Heat Recovery Plants

· Flue gas coolers

Laser welded stainless finned tube in Heating Industry

· Primary heat exchangers in gas heating boilers

· Secondary heat exchangers for domestic water heating in condensing boilers

Laser welded stainless finned tube in General Engineering

· Heat exchangers for gas cooling of industrial furnaces

· Heat exchangers for tank heating

· Oil coolers for vacuum plants, ship plants, pumps etc.

· Heat exchangers for oil preheating |