What are studded pipes?

Tubes with welded-on studs are commonly used in fired boilers and furnaces in petrochemical refineries. Because of the high heat transfer and ease of aggressive cleaning, studded tubes are preferred over finned tubes for surfaces exposed to highly corrosive environments and dirty gas streams.

Welding fin tube is a new kind of heat transfer material which has the feature of wearing resistance and high efficient. And it is a kind of high efficiency and energy saving heat transfer element.

Studded tube adopts middle frequency welding spiral technology, the national patent technology with high frequency power supplies as the heat source to heat the steel strip, steel pipe at the same time, make its welded together as a whole. This technology has the characteristics as high in thermal efficiency, large heat dissipation area, long service life, range adaptation temperature, high pressure, etc.

Studded tube widely used in waste heat recovery, petrochemical industry, power plant boiler, economizer, coaches, civil building heating, refrigerating, drying, medicine of wood drying, food drying system and other industries.

The advantages of welding studded tube:

1. The simple and economic installation

The maximum length of high frequency welding spiral finned tube can reach 6 meters, that reduces the join points, making the installation more economic, efficient, and also reduces the leakage probability of joints.

2. Easy maintenance

After installation, high frequency welding spiral fin tube needs no longer to be maintained.

3. High efficiency

The heat dissipation area of high frequency welding spiral fin tube is more than 8 times of the light tube.The internal is smooth, so the internal flow resistance is small.

4. Long service life

Fin and pipes with high mechanical strength, so the tensile strength is more than 200 mpa. Both inside and outside of the tube are all made of hot dip galvanized processing.

Welding Studded Tube material:

Weldable fin material: carbon steel, stainless steel, alloy steel, corrosion resistant steel. These tubes are specially used in petroleum applications.

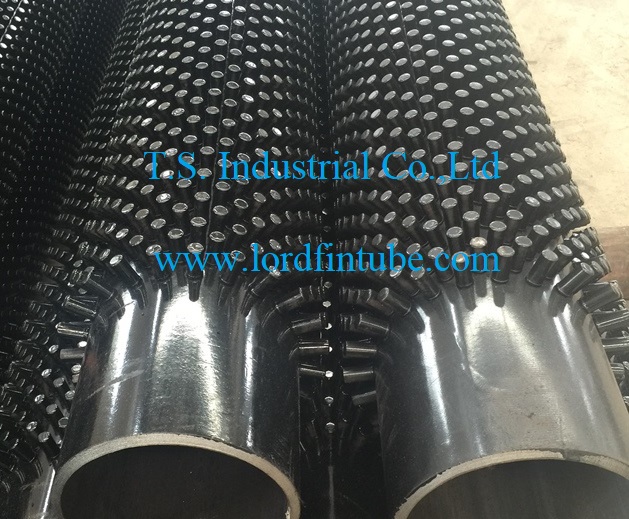

The studs are arranged in staggered rows (rings).

All tubes and studs material combination can be manufactured: Carbon, stainless, and alloy steels.

Welding Studded Tube|studded pipes |