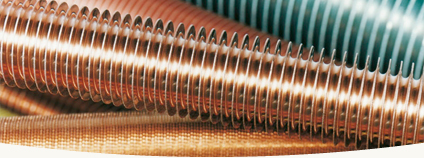

What is single metal finned tube?

Single metal finned tubes are formed from plain tubes that have been shaped. They are used as components in heat exchangers that are highly efficient, compact, and extremely stable. Tube surfaces are tailored to the applications specific heat transfer requirements. We use a wide range of materials to ensure that the material best suited to the specific needs, such as durability and formability, is used.

Single metal finned tube is alos a kind of Integral finned tubing

Single metal finned tube for the winding type, the fin was inverted Y-type. Is the base tube fixed in a 360 ° rotation of the drive winding device, and then according to the different film height, chip distance, select the different types of fixtures. Fins are ribbon-like, through the fixture when the initial shape depends on the mechanical tension of the fins forming a winding on the base tube.

Single metal finned tube features:

1. Small distance from 0.5-2.11mm, the film thickness is generally 0.2-0.5mm, the unit heat transfer area is small, relatively large contact resistance.

2. As a single metal finned tube is to rely on the bottom of the fold evenly standing on the base pipe, the bottom of the fold can play a role in the external air spoiler, to strengthen the heat transfer is good. At the same time, the bottom of the fold also increased the side of the gas resistance, and prone to fouling in the folds and other phenomena for the exclusion of condensate and dust cleaning increased the difficulty of selection must be noted.

3. Single metal finned tube also has a convenient material, processing is difficult, the manufacturing cost is light and so on. The fins of a single metal fin tube do not completely cover the base pipe, and the base pipe is exposed to air and is susceptible to corrosion

How to fabricate the Integral finned tubing?

This finned surface is formed as a thick walled aluminum tube or copper alloy tube or carbon steel tube or stainless steel tube, then they are put through cold rotary extrusion, forming fins that are much longer in diameter than the original tube.

This process hardens the aluminum so the fins are very strong, resulting in optimal heat transfer efficiency and exceptional durability. It can be applied to single aluminum tubes (mono aluminum tube) or with the addition of a liner tube within the original aluminum tube (bi-metal).

With bi-metal tubing, the fin material is always aluminum and the liner is usually copper-nickel, stainless steel or titanium, with the extrusion process creating a very strong mechanical bond between the two. The result is a rugged, reliable heat transfer surface with fins that do not break, unwind or become loose with subsequent loss of capacity.

Single metal finned tube|Integral finned tubing |