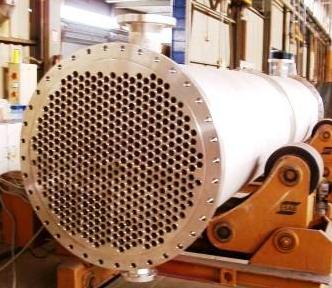

We designs,manufactures and construction Shell & Tube heat exchangers in accordance with TEMA. TEMA Class “R” shell and tube heat exchangers for generally severe requirements of petroleum and related processing applications; TEMA Class “C” shell and tube heat exchangers for generally moderate requirements of commercial and general process applications and Class “B” for chemical process service.

• Potential large heat transfer area with high heat transfer efficiency

• Flexible designs able to meet many different process requirements

• Steady heat transfer by utilizing multiple passes of one or both fluids

• High design pressures, typically up to 200bar, however can be significantly greater

• High design temperatures with large temperature ranges

• Manufactured to all design codes including ASME VIII; EN13445; PD5500

• Fully compliant with PED 97/23/EC including CE Marking with possible ASME “U-Stamp”

• Wide range of metallurgies including Carbon Steel, Stainless Steel, 22%Cr & 25%Cr Duplex, 254SMO and Titanium material

Shell & Tube heat exchangers operational benefits

• Reliable with limited maintenance requirements

• High working temperatures and pressures; operational flexibility

• High safety (tube-bundle inserted into pressure vessel; no fluid mixing)

• Can handle thermal shocks

• No leakages; environmental protection

Shell & Tube heat exchangers applications:

• Oil & Gas Production and Refining

• Chemical Processing

• Pharmaceuticals & Speciality Chemicals

• HVAC, Heat Recovery, Energy & Utilities

• Power Generation

• Nuclear

Shell & Tube heat exchangers example fluid combinations include:

• Water / Sea Water / Steam

• Homogeneous and low viscous fluids

• Amine / Glycols

• Hydrocarbons

• Condensate

• Petrochemical fluids

Shell & Tube heat exchangers Materials of Construction Weld procedures cover a wide variety of metals including stainless steel, Duplex stainless steel, copper alloys, Copper Nickel (CuNi), Inconel, Monel, Haynes Alloys, titanium, and other exotic alloys.

Shell & Tube Heat Exchangers

Publisher:Lord Fin Tube |