Boiler steel pipes are specialized components engineered for extreme conditions in power generation, industrial heating systems, and high-temperature applications. These critical components transport high-temperature fluids including steam, hot water, and thermal oils while maintaining structural integrity under immense pressure and thermal stress.

Complete Standards Specifications

ASTM Standards (American Society for Testing and Materials)

- ASTM A106: Grade A, B, C - Seamless carbon steel pipe for high-temperature service

- ASTM A53: Grade A, B - Welded and seamless steel pipe

- ASTM A178: Grade A, C, D - Electric-resistance-welded steel boiler tubes

- ASTM A192: Seamless carbon steel boiler tubes for high-pressure service

- ASTM A210: Grade A-1, C - Seamless medium-carbon steel boiler and superheater tubes

BS Standards (British Standards)

- BS 3059:

- Part 1: 320 CFS

- Part 2: 360, 440, 243, 620-460, 622-490

- Specifications: S1, S2, TC1, TC2

EN Standards (European Norm)

- EN 10216-1:

- P195TR1/TR2

- P235TR1/TR2

- P265TR1/TR2

- EN 10216-2:

- 195GH

- P235GH

- P265GH

- TC1, TC2

DIN Standards (German Institute for Standardization)

JIS Standards (Japanese Industrial Standards)

GB Standards (Chinese National Standards)

- GB 5310:

- 20G

- 15MoG

- 12Cr2MoG

- 15CrMoG

- 12Cr1MoVG

- 12Cr2MoWVTiB

- GB 9948: 10, 20, 12CrMo, 15CrMo

- GB 3087: 10, 20

Technical Specifications Range

Outside Diameter (O.D):

8 - 168.3 mm

Wall Thickness (W.T):

1 - 15 mm

Delivery Condition:

Annealing, Normalizing, Normalizing + Tempering

Surface Treatment:

Oil immersion, Spray paint, Passivation, Phosphating, Shot blasting

Applications & Service Conditions

High Pressure Boilers

Power plant boilers operating above 1000 PSI

Medium Pressure Boilers

Industrial process boilers (150-1000 PSI)

Low Pressure Boilers

Heating systems and small industrial units

Pressure Vessels

Heat exchangers and storage containers

Quality Testing & Certification

Chemical Analysis

Complete chemical composition testing to verify material grade compliance with specified standards

Mechanical Testing

Tensile strength, yield strength, elongation, hardness, and impact testing at various temperatures

Process Performance

Flattening test, flare test, bending test, hardness test, impact test to verify manufacturing quality

Non-Destructive Testing

Ultrasonic testing, radiographic examination, hydrostatic testing, dimensional inspection

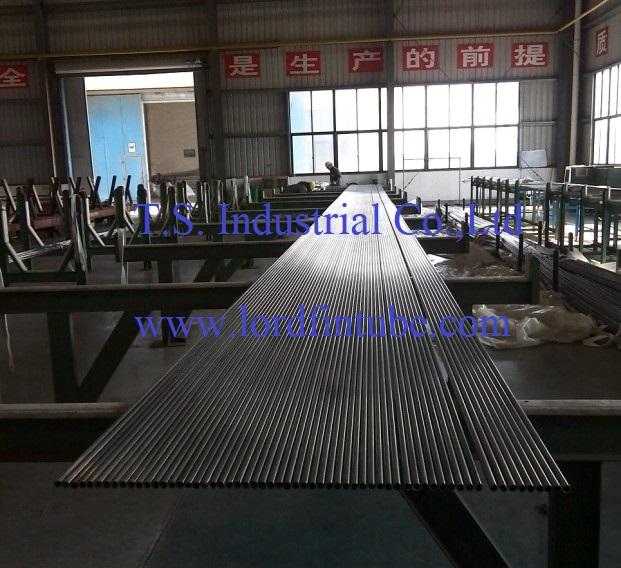

High-quality boiler steel pipes undergoing dimensional inspection and quality control

Material Grades & Composition Requirements

| Standard |

Grade |

C (%) Max |

Mn (%) |

Other Key Elements |

| ASTM A106 |

Grade B |

0.30 |

0.29-1.06 |

P: 0.035, S: 0.035 |

| ASTM A53 |

Grade B |

0.30 |

1.20 |

P: 0.05, S: 0.045 |

| GB 5310 |

20G |

0.17-0.24 |

0.35-0.65 |

Si: 0.17-0.37 |

| DIN 17175 |

ST35.8 |

0.17 |

0.40-0.80 |

P: 0.025, S: 0.020 |

Insight: Each standard specifies not only chemical composition but also mechanical properties, heat treatment requirements, testing methods, and acceptable defect levels. Proper material certification including mill test certificates (MTC) is essential for compliance with pressure equipment directives.

Boiler Steel Pipe Application

| Application Type |

Recommended Standards |

Temperature Range |

Pressure Range |

| Superheater Tubes |

ASTM A213, GB5310 alloy grades |

Up to 650°C |

Very High |

| Water Wall Tubes |

ASTM A178, ASTM A192 |

200-400°C |

High |

| Economizer Tubes |

ASTM A106, GB3087 |

100-300°C |

Medium-High |

| Low Pressure Heating |

ASTM A53, DIN 1629 |

Up to 200°C |

Low-Medium |

Comprehensive Technical Coverage

This guide provides complete technical specifications for boiler steel pipes including ASTM A106 grade B chemical composition, GB5310 20G mechanical properties, DIN 17175 ST35.8 application guidelines, JIS G3461 STB410 pressure ratings, and comprehensive international standards comparison for boiler tubing selection and specification.

Global Standards Compliance

Understanding the relationship between different international standards is crucial for global projects:

- ASME Boiler and Pressure Vessel Code: References ASTM materials for construction

- PED (Pressure Equipment Directive): European compliance requiring CE marking

- ISO 9329: International standardization of steel pipes for pressure purposes

- TRD (Technical Rules for Steam Boilers): German regulations for boiler components

Proper selection of boiler steel pipes requires not only understanding material specifications but also compliance with relevant pressure equipment regulations and industry-specific requirements. The comprehensive standards coverage provided here serves as an essential reference for engineers, procurement specialists, and quality assurance professionals working with high-temperature pressure systems.