Advancing Heat Exchange Technology: The Hot-Dip Galvanized Elliptical Fin Tube

Hot-Dip Galvanized Elliptical Fin Tube Introduction:

The hot-dip galvanized elliptical fin tube stands as a testament to its enduring market presence and exceptional performance in heat exchange applications. With a proven track record spanning decades, this innovative tubing solution continues to be a pivotal player in various industrial sectors.

Unrivaled Performance Across Industries:

Renowned for its favorable flow characteristics, the elliptical fin tube has solidified its position in critical industries including:

- Refineries

- Petrochemical industry

- Steel mills and related sectors

- Natural gas facilities

- Power plants

- Paper industry

- Textile industry

Hot-Dip Galvanized Elliptical Fin Tube with Engineering Excellence:

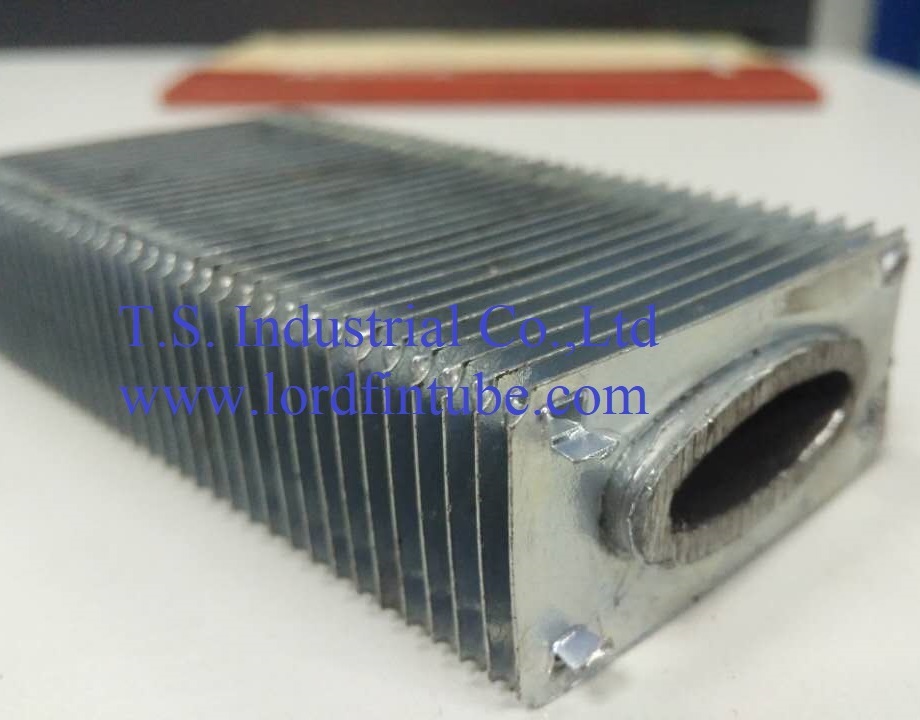

Featuring rectangular fins meticulously arranged over an oval tube, this design not only enhances heat exchanger efficiency but also minimizes heat transfer and pressure loss. Key specifications include:

- Fin pitch (mm): 2.3, 2.5, 2.8, 3.2

- Fin quantity (pcs/m): 416-455, 390-410, 345-370, 302-322

- Heat transfer area (square meter/m): 1.15, 1.05, 0.95, 0.85

- Weight (Kg/m): 2.0/2.5, 3.0/3.3, 2.9/3.1, 2.7/3.0, 2.5/2.8

- Tube material: Carbon steel tubes (seamless or welded pipes)

- Bare tube (mm): Long 36-0.2, Short 14-0.2

- Fin material: SPCC

- Fin size (mm): 55*26*0.25

- Zinc layer (mm): 0.05-0.07

- Turbulator quantity: 4pcs, 10 pcs, or 26 pcs

- Length (m): 15000mm

Hot-Dip Galvanized Elliptical Fin Tube with Innovative Manufacturing Processes:

The manufacturing process of fin chip inserted finned tubes involves punching single fins, followed by manual or mechanical insertion onto the base tube at specific intervals (fin pitch). This labor-intensive process, while cost-effective, is best suited for smaller factories or enterprises with limited technical capabilities.

Hot-Dip Galvanized Elliptical Fin Tube Ensuring Quality and Reliability:

Manual insertion of fins allows for limited pressure, potentially leading to loose fins. In contrast, mechanical insertion applies higher pressure, ensuring a robust bond between the fin and tube. However, this method comes with increased noise and safety concerns. Although hydraulic methods address some of these issues, they come with higher equipment costs and require more technical expertise, ultimately impacting productivity.

Hot-Dip Galvanized Elliptical Tube with Rectangular Fins |