What is bended integral finned tube?

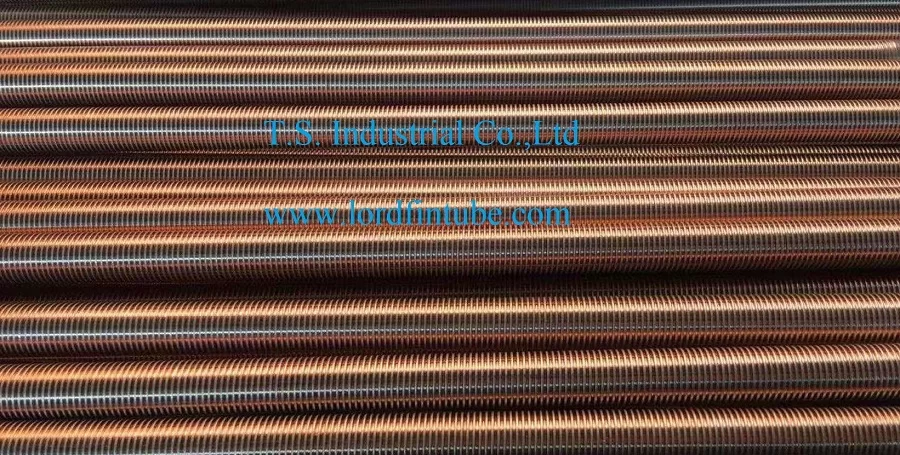

A bended integral finned tube is a type of heat transfer component used in various industrial applications, particularly in heat exchangers. It is designed to enhance heat transfer efficiency by incorporating spiral fins on the outer surface of a tube.

The manufacturing process involves extruding fins onto the outer surface of plain tubes, after which the tube is bent to form the desired shape with the fins intact. Finally, the bend parts are heat-treated to ensure structural integrity and optimal performance.

The spiral fins increase the surface area of the tube exposed to the surrounding fluid, facilitating better heat transfer between the fluid and the tube. This design typically results in a heat transfer performance enhancement of around 1.6 to 2.0 times compared to plain tubes, making bended integral finned tubes an efficient solution for heat exchange applications.

Bended integral finned tube Material:

Carbon steel tube;Alloy steel tube. Other specificationsGeneral specifications are as follows. In the case you require more severe condition, always we do our best for your requirement.

1.After fin process, we do eddy current examination. On your order, we check SR for all materials.

2.Minimum length of middle land should be 25±5mm, minimum length of ends land should be 25±5mm.

3.Total imperfect length of fin ends is less than 120mm.

4.Maximum length of fin process is 19.5m. Torelance specification is +10mm/-0 or ±5mm.

5.Bended integral finned tube is available. Bended area is available as both finned and flat.

Bended integral finned tube usage:

1. Petroleum Refinery Plant: In petroleum refineries, bended integral finned tubes can be employed in heat exchangers for processes such as crude oil distillation, refining, and various chemical processes. They facilitate the exchange of heat between different streams of fluids, optimizing energy efficiency in refinery operations.

2. Petrochemical Plant: Similar to refinery plants, petrochemical plants utilize bended integral finned tubes in heat exchangers for processes involving the production of petrochemicals such as ethylene, propylene, benzene, and others. These tubes help maintain precise temperature control in various stages of chemical reactions and separation processes.

3. Turbofan Refrigerator: In turbofan refrigerators or air cycle refrigeration systems, bended integral finned tubes can be used in heat exchangers to cool the compressed air before it enters the expansion turbine. This cooling process improves the efficiency of the refrigeration cycle by lowering the temperature of the air and increasing its density, resulting in more effective cooling of the conditioned space or equipment.

Bended integral finned tube

Bended integral finned tube standard size:

The standard size of integral finned tube is as follows. mm

|

Material size

Diameter/thickness(average)

|

Number of fins

(Fins per 25.4㎜)

|

Fin

Outside diameter

|

Root diameter

|

Bottom of fin

Minimum thickness

|

Outer surface area

average (m2/m)

|

Ratio of surface area

Outer surface/Inner surface

|

Product number

|

|

15.88/1.91

|

19

|

≦15.98

|

12.70

|

1.27

|

12.34/10-2

|

3.99

|

|

|

15.88/2.11

|

1.47

|

4.18

|

|

|

19.05/1.65

|

≦19.15

|

15.88

|

1.12

|

15.12/10-2

|

3.60

|

|

|

19.05/1.91

|

1.27

|

3.69

|

|

|

19.05/2.11

|

1.47

|

3.84

|

|

|

19.05/2.28

|

1.65

|

3.94

|

|

|

19.05/2.54

|

1.88

|

4.13

|

|

|

19.05/2.77

|

2.13

|

4.35

|

|

|

25.40/2.54

|

≦25.55

|

22.23

|

1.88

|

20.67/10-2

|

3.65

|

|

|

25.40/2.77

|

2.13

|

3.83

|

|

|

25.40/3.05

|

2.46

|

3.98

|

|

Publisher:Lord Fin Tube |