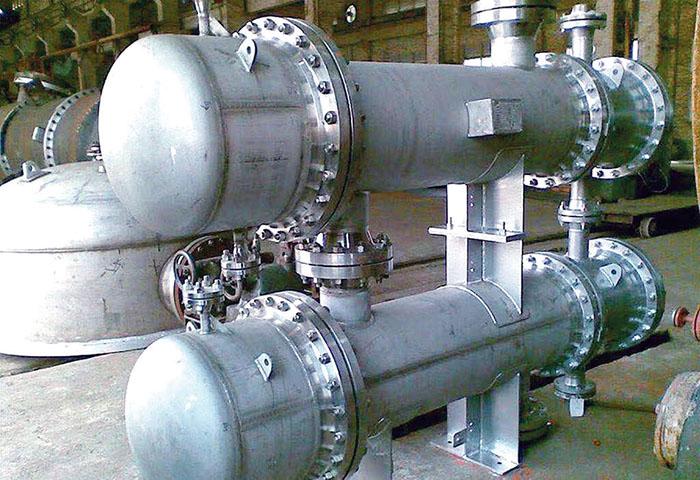

The Guide to Choosing Shell and Tube Heat Exchangers for Industrial Applications

Shell and tube heat exchangers are renowned for their efficiency and durability, making them a preferred choice across various industries. Comprising a shell that houses a bundle of tubes, these heat exchangers facilitate the transfer of heat between two fluids—one flowing through the tubes and the other around them within the shell. Here’s why shell and tube heat exchangers stand out as the ideal solution for many industrial applications. Shell and tube heat exchangers are widely utilized across various industries, especially in refineries, due to the numerous benefits they provide compared to other types of heat exchangers. They offer higher heat transfer efficiency and are more cost-effective than plate-type coolers.

Unmatched Heat Transfer Efficiency

The primary advantage of shell and tube heat exchangers lies in their high heat transfer efficiency. The design maximizes surface area contact between the fluids, ensuring effective heat exchange. Enhanced performance is crucial for applications requiring rapid and efficient heat transfer.

Versatile Applications and Fluid Compatibility

Shell and tube heat exchangers are incredibly versatile, suitable for heating, cooling, and condensing tasks in industries such as chemical processing, power generation, and HVAC. They handle a wide range of fluids, including water, steam, oil, and gas, making them adaptable to various processes.

Durability and Low Maintenance

These heat exchangers are built to withstand harsh operating conditions, offering robust construction that ensures longevity. Maintenance is straightforward due to the easy access provided to the tubes, allowing for quick cleaning and inspection, thereby minimizing downtime and maintenance costs.

High-Pressure Handling

Capable of handling high-pressure fluids, shell and tube heat exchangers are ideal for demanding industrial applications. Their ability to operate safely under high pressures enhances their reliability in critical processes.

Cost-Effective Solution

Balancing performance with cost, shell and tube heat exchangers are a cost-effective option. Their efficiency, combined with low maintenance requirements, translates to reduced operating expenses over time. The durable construction also means fewer replacements and repairs, further contributing to cost savings.

Scalability and Customization

The scalability of shell and tube heat exchangers is a significant advantage. Customizable in terms of the number of tubes, shell size, and overall configuration, they can be tailored to meet specific capacity and performance needs, from small-scale operations to large industrial systems.

Thermal Expansion Management

These heat exchangers effectively manage differential thermal expansion between the shell and tubes, essential for processes involving significant temperature variations. This capability ensures consistent performance and safety under varying thermal conditions.

Material Versatility

Constructed from a variety of materials such as carbon steel, stainless steel, titanium, and copper alloys, shell and tube heat exchangers can be tailored for specific corrosive environments and high-temperature applications, enhancing their applicability across different industries.

Design Flexibility

Offering various configurations like U-tube, straight-tube, and floating head designs, these heat exchangers provide flexibility to meet specific operational and maintenance needs. Multi-pass options on both the tube and shell sides optimize heat transfer and pressure drop according to process requirements.

Enhanced Heat Transfer with Segmental Baffles

Segmental baffles within the shell improve turbulence, enhancing heat transfer efficiency and preventing hot spots. These baffles also provide structural support to the tubes, reducing the risk of vibration and damage.

Ease of Inspection and Testing

Shell and tube heat exchangers are easily inspected using non-destructive testing methods such as ultrasonic testing, eddy current testing, and radiographic testing. This ensures integrity and performance without the need for disassembly. The design allows straightforward visual inspection for early detection of issues.

Multiple Service Capabilities

Besides sensible heat transfer, these exchangers excel in condensing vapors and vaporizing liquids, making them versatile for phase-change applications. They are often integrated with cooling towers in HVAC systems, enhancing overall system efficiency.

Compact and Modular Design Options

Optimized designs can provide high performance in a relatively compact footprint, suitable for space-constrained environments. Modular designs offer the flexibility of easy capacity expansion by adding more shells or tube bundles.

Advanced Thermal Design Software

Sophisticated thermal design software allows precise modeling of heat exchanger performance, ensuring optimal design and operation tailored to specific process conditions. Simulation capabilities help predict performance under varying loads and conditions.

Critical Industry Applications

In nuclear power plants, shell and tube heat exchangers handle radioactive fluids and provide reliable heat transfer. In the petrochemical industry, they are used for process heating and cooling, often dealing with highly corrosive and high-temperature fluids.

Compliance with Standards and Certifications

Manufactured to comply with international standards and certifications like ASME, TEMA, and API, shell and tube heat exchangers ensure high quality and safety in critical applications. They can meet specific industry requirements and regulatory compliance, ensuring compatibility with existing systems.

Shell and tube heat exchangers offer unparalleled efficiency, versatility, durability, and cost-effectiveness, making them an excellent choice for a wide range of industrial applications. Their ability to handle high pressures, manage thermal expansion, and provide customizable solutions further solidify their position as a reliable and efficient heat transfer solution. Not matter for small-scale operations or large, complex systems, shell and tube heat exchangers deliver exceptional performance and longevity.

Shell and tube heat exchangers |