What is an integral spiral finned tube?

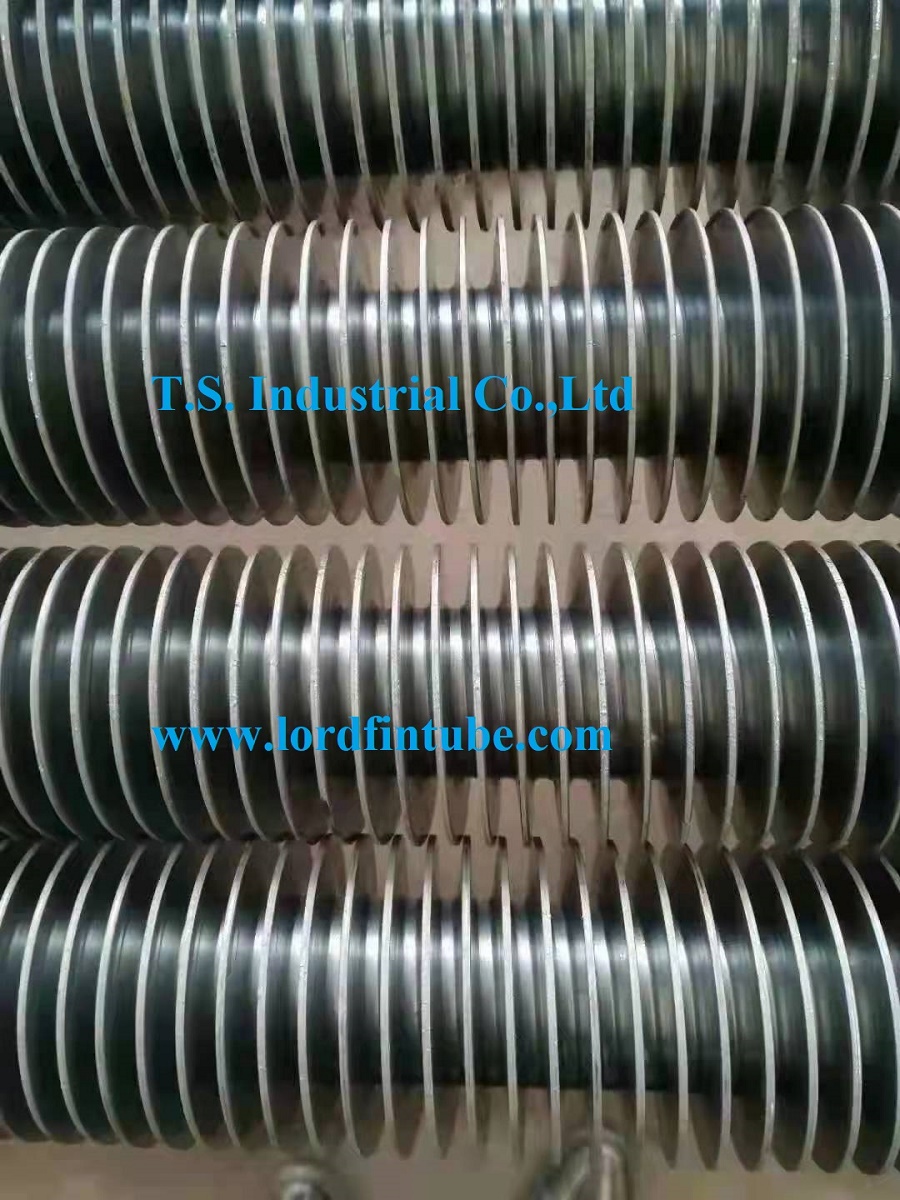

The integral spiral finned steel pipe is formed by hot rolling and extrusion of thick-walled seamless steel pipe.

Integral spiral finned tube production process:

The specific production process of the integral spiral finned tube is as follows: the thick-walled seamless steel tube is heated to 900-950°C by 2000HZ-2500HZ intermediate frequency induction, and automatically enters three sets of special rolling blades distributed at 120° in the circumferential direction, and the thick-walled seamless steel tube One-time rolled into a spiral finned tube with wall thickness, wing height, wing pitch, and wing shape meeting the requirements Spiral fins that meet the requirements) and the fins and tubes are integrally structured, and the surface of the fins is flat and smooth.

Technical advantages of integral spiral finned tubes:

Most of the spiral finned steel tubes used today are wound finned tube, high frequency welded finned tube and brazed spiral finned steel tubes. Integral spiral-finned steel pipes have long service life, stable heat transfer performance, and obvious energy-saving effect. They have become the replacement products of the above three types of spiral-finned steel pipes. Their advantages are shown in the following aspects:

1. The integral spiral finned tube has a long service life, which is more than three times that of the wound welded finned steel tube.

2. The root of the integral spiral finned tube forms an arc cut with the tube, and the surface of the fin is smooth, which completely eliminates the phenomenon of dust accumulation, dust blocking and slagging caused by the uneasy folding of the root of the finned tube of other forms.

3. The integral spiral finned tube is produced by hot rolling and rolling process, which improves the density, yield strength, tensile strength and wear resistance of the metal structure.

4. Integral spiral-finned tubes As the fins and tubes are integrally structured and distributed in spiral bands, the pressure-bearing capacity of integral spiral-finned steel tubes is more than three times that of seamless steel tubes with equal wall thickness and the same inner diameter.

5. The integral spiral finned tube is wear-resistant, which solves the problem of serious wear and tear on the convection heating surface of the coal-fired boiler due to high wind speed and high ash concentration. (especially circulating fluidized bed boilers)

6. Integral spiral finned tube The fin and tube are integrated structure, which completely eliminates the contact thermal resistance that other forms of finned steel tubes cannot overcome due to the two-body structure of the fin and the tube, and the longitudinal section of the fin has a trapezoidal structure. Therefore, the fin heat transfer efficiency is improved to the greatest extent.

7. The integral spiral finned tube adopts the integral spiral fin extended surface heat transfer. Under the same working conditions, the heat transfer coefficient of the tube bundle is 3.5-5.5 times that of the seamless steel pipe with the same wall thickness and the same inner diameter, which is welded with the same specification. 2 times that of spiral finned steel pipe.

8. Integral spiral finned tube The fin and the tube are integrated structure, so it is used in the workplace with high temperature and harsh environment, and there will be no heat transfer caused by loose fins and falling off that other forms of finned steel tubes tend to produce. Unstable performance.

Integral spiral finned tube application fields:

Integral spiral finned tubes can be widely used in power plant boilers, waste heat boilers, ships, steel, petroleum, chemical, refrigeration, HVAC and other industrial and civil heat exchange fields.

Integral finned tube|Integral spiral finned tube

|