What is a helical baffle heat exchanger?

The spiral baffle heat exchanger is based on changing the arrangement of the baffle plates at the shell side to make the fluid at the shell side show a continuous spiral flow. Therefore, the ideal baffle plate arrangement should be a continuous spiral curved surface. However, it is difficult to process the spiral curved surface, and it is also difficult to achieve the matching between the heat exchange tube and the baffle plate. Considering the convenience of processing, a series of fan-shaped flat plates (called spiral baffle plates) are used to replace the curved surface to connect each other, An approximate spiral surface is formed on the shell side to make the fluid on the shell side produce an approximate continuous spiral flow. Generally speaking, for processing considerations, a screw pitch is taken as 2~4 baffle plates. There are two modes of continuous overlap and staggered overlap between adjacent baffle plates. According to the flow channel, it can be divided into single spiral and double spiral structures.

The most common application of the traditional heat exchanger is the segmental baffle. Due to the existence of large drag and pressure drop, flow stagnation zone, easy scaling, the average temperature difference of heat transfer is small, the vibration conditions are easy to failure and other defects. The ideal helical baffles should have a continuous spiral surface. Due to the processing difficulties, the current use of the baffle plate, usually by a number of 1/4 sector of the plane to replace the curved surface of the connection, the formation of the spiral surface approximation. At the time of the flow, the fluid is in a state of approximate spiral flow. In the same working condition, the baffle plate (called the non continuous spiral baffle) can reduce the pressure drop of about 45%, and the total heat transfer coefficient can be increased by 30% ~ 20%, which can be greatly reduced by the same heat load.

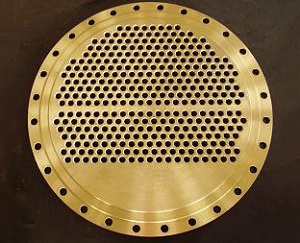

Tube shell type heat exchanger has the advantages of convenient cleaning and so on, which occupies an important position in the fields of petroleum, chemical, oil refining, nuclear energy utilization and so on. As the direction of fluid flow in the shell side changes frequently, and there are leakage and other phenomena, so the shell side flow and heat transfer is the bottleneck of the heat exchanger. Heat exchanger of arch folded plate heat exchanger is the most commonly used a conventional shell and tube exchanger, but its disadvantages is pressure drop along the path of the larger; prone flow dead zone, adjacent to the flow and leakage, and is easy to fouling; high quality velocity to induce heat exchange tube vibration, shortened the life span. In view of the shortcomings of the shell side flow, people put forward the concept of spiral baffle plate heat exchanger (Figure), and in early 1990s by ABB company developed a series of products, in practical application has achieved good results, especially for high viscosity fluid effect is more prominent.

Segmental baffle |