Why use fin tubes in heat exchanger?

The advantages of using finned tubes in heat exchangers are evident. Finned tubes increase heat transfer surface area, enhance heat transfer efficiency, and save space. Their design also allows for more precise control of fluid temperature, reduces fouling, and prolongs the lifespan of the heat exchanger. Consequently, finned tubes have become an indispensable component in heat exchanger design.

1. Fin Tube Increasing Heat Transfer Surface Area:

- Heat Transfer Mechanism: Heat transfer processes depend on the heat transfer surface area. Finned tubes effectively increase the surface area in contact with the fluid by adding fins on the external surface of the tubes. This increases the total heat transfer surface area of the heat exchanger, thereby improving heat transfer efficiency.

- Surface Area Calculation: The heat transfer surface area of finned tubes can be adjusted by factors such as the number, shape, size, and spacing of the fins. Typically, more, longer, and denser fins result in a larger heat transfer surface area.

- Application Examples: Increasing heat transfer surface area is crucial in applications requiring handling large amounts of heat, such as cooling or heating in industrial production processes. Finned tubes provide an effective means to achieve this goal.

2. Fin Tube Enhancing Heat Transfer Efficiency:

- Heat Transfer Enhancement: Finned tubes not only increase the heat transfer surface area but also enhance heat transfer by altering the flow patterns around the fluid. This heat transfer enhancement often manifests as stronger convective heat transfer, thereby improving heat transfer efficiency.

- Increase in Heat Transfer Coefficient: The use of finned tubes can lead to higher convective heat transfer coefficients since they can generate stronger turbulence around the tubes. This means more heat can be transferred per unit time, resulting in higher efficiency of the heat exchanger.

- Application Examples: In applications requiring rapid and efficient transfer of heat from one medium to another, such as in air conditioning systems or chemical processes, finned tubes can significantly improve heat transfer efficiency, thus reducing energy consumption and costs.

By increasing heat transfer surface area and enhancing heat transfer efficiency, finned tubes play a crucial role in heat exchangers, especially in applications requiring handling large amounts of heat while ensuring efficient heat transfer.

3. Fin Tube Can Space Saving:

Finned tubes can be designed very compactly, making them very practical in applications with limited space, such as automotive engine radiators and air conditioning systems.

4. Temperature Control:

By adjusting the design parameters of fins, such as density and thickness, the fluid temperature can be controlled more precisely, making the heat exchanger more flexible in temperature control.

5. Prevention of Fouling:

The design of finned tubes can reduce fouling on the surface of the tubes, thereby reducing maintenance requirements and maintaining heat transfer performance.

Finned tubes are suitable for use in the following types of heat exchangers:

- Air Coolers (Air Cooled Heat Exchangers):

Air coolers are typically used to cool gases or liquids, where air is used to transfer heat through finned tubes. Since finned tubes increase the heat transfer surface area, they are well-suited for air coolers to enhance cooling efficiency.

- Radiators:

Radiators are used to transfer heat from a liquid to air. Finned tubes can provide a larger heat transfer surface area in radiators, making them commonly used in applications such as automotive engine radiators and electronic equipment radiators.

- Evaporators and Condensers:

In applications requiring liquid evaporation or condensation, finned tubes can provide a more effective heat transfer surface, thereby improving the efficiency of evaporators and condensers.

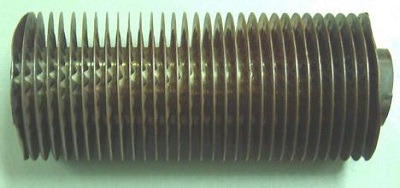

Fin Tube in heat exchanger |