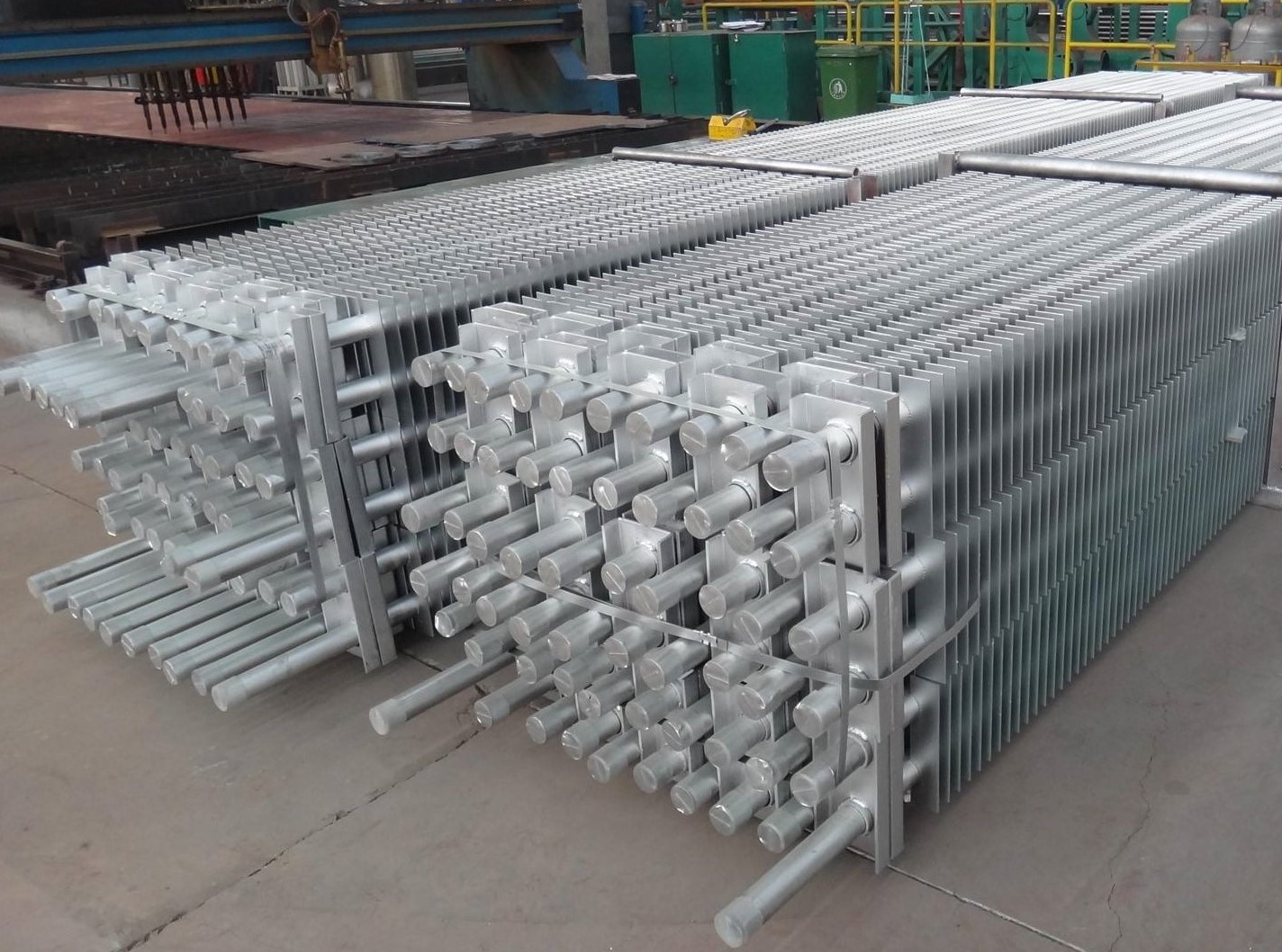

Customized economizer for Heat recovery

1. What is customized economizer for heat recovery?

A customized economizer for heat recovery is a device or system used to improve the energy efficiency of industrial processes by recovering waste heat from flue gases or exhaust streams. The economizer captures and utilizes the heat that would otherwise be lost to the environment, typically transferring it to a fluid (such as water or air) for heating purposes or for preheating combustion air or process fluids.

2. Customized economizer for heat recovery materials used:

The materials used in a customized economizer for heat recovery depend on the specific application, operating conditions, and the type of fluid being heated. However, commonly used materials include:

- Heat exchanger tubes: Stainless steel, carbon steel, or alloy steel.

- Finned tubes: Aluminum, copper, or steel.

- Shell or housing: Carbon steel or stainless steel.

- Insulation: Mineral wool, ceramic fiber, or other suitable insulation materials.

The selection of materials is crucial to ensure durability, corrosion resistance, and efficient heat transfer under the operating conditions of the economizer.

3. Customized economizer for heat recovery advantages:

Customized economizers for heat recovery offer several advantages:

- Energy efficiency: By recovering waste heat and utilizing it for other heating purposes, economizers can significantly improve the energy efficiency of industrial processes. This can lead to reduced fuel consumption and lower operating costs.

- Cost savings: Recovering waste heat means less energy needs to be supplied by primary energy sources, resulting in cost savings on fuel or electricity bills.

- Environmental benefits: Utilizing waste heat reduces greenhouse gas emissions and helps in achieving sustainability goals by minimizing the overall energy consumption of the process.

- Customizability: These economizers can be tailored to specific applications, allowing for optimal heat recovery based on the characteristics of the exhaust stream and the desired heat transfer medium.

- Versatility: Customized economizers can be integrated into various industrial processes, including power generation, chemical manufacturing, cement production, refineries, and many other industries where waste heat is generated.

4. Customized economizer for heat recovery applications:

Customized economizers for heat recovery find applications in numerous industries and processes, including:

- Power plants: Recovering waste heat from flue gases to preheat feedwater or generate additional steam.

- Industrial boilers: Preheating combustion air, preheating process fluids, or generating hot water for various industrial applications.

- Refineries: Utilizing waste heat from process exhaust streams to preheat crude oil or other feedstocks.

- Chemical plants: Recovering heat from chemical reactions or process exhaust streams for use in other process steps.

- Cement production: Capturing waste heat from kiln exhaust gases and utilizing it for preheating raw materials or fuel.

These are just a few examples, and customized economizers can be designed and implemented in various other industries where waste heat is available and can be effectively recovered.