Lord Fin Tube-Embedded Fined tube

What are Embedded Finned Tubes?

Embedded finned tubes represent a sophisticated heat exchange technology designed to maximize thermal efficiency in demanding industrial environments. These specialized components feature fins that are mechanically integrated into grooves on the base tube surface, creating a permanent, high-performance bond that significantly enhances heat transfer capabilities.

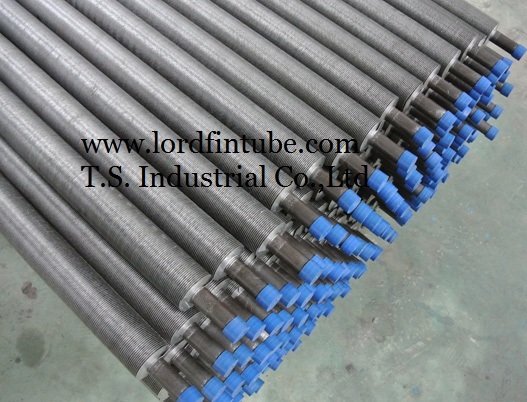

High-performance embedded finned tubes for industrial heat exchangers

Advantage: Embedded finned tubes provide up to 10x greater heat transfer efficiency compared to bare tubes, making them ideal for applications where space constraints and thermal performance are critical factors.

Embedded Fined tube Manufacturing Process

The production of embedded finned tubes involves precision engineering to ensure optimal performance and durability:

Base Tube Materials

| Material Type | Standards | Temperature Range | Primary Applications |

|---|---|---|---|

| Carbon Steel | ASTM A179, A192, A210 A1 | -20°C to 450°C | General purpose heat exchangers, boilers |

| Alloy Steel | ASTM A213 T5, T11, T22, T9 | -50°C to 600°C | High-temperature applications, power plants |

| Stainless Steel | ASTM A213 TP304/304L, TP316/316L | -200°C to 800°C | Corrosive environments, food processing |

| Duplex Stainless Steel | ASTM A789 S31803 | -50°C to 300°C | Chemical processing, offshore applications |

| Nickel Alloys | Alloy 600, 601, 625, 825, C276, 400 | -200°C to 1100°C | Extreme environments, aerospace, nuclear |

| Copper Alloys | ASTM B111 C12200, C44300, C68700, B70600, B71500 | -100°C to 250°C | Marine applications, refrigeration |

Fin Materials

Embedded Fined tube vs Other Fin Types

| Parameter | Embedded Finned Tubes | Extruded Finned Tubes | Welded Finned Tubes |

|---|---|---|---|

| Thermal Efficiency | Excellent (85-95%) | Good (75-85%) | Very Good (80-90%) |

| Corrosion Resistance | Very High | High | Medium |

| Mechanical Strength | Excellent | Good | Very Good |

| Temperature Range | -200°C to 600°C | -100°C to 350°C | -50°C to 500°C |

| Pressure Resistance | Very High | Medium | High |

| Cost Efficiency | Medium-High | High | Medium |

Benefits of Embedded Finned Tubes

Enhanced Heat Transfer

Increased surface area improves thermal efficiency by up to 10x compared to bare tubes, reducing equipment size and energy consumption.

Superior Durability

Mechanical bonding ensures fins remain securely attached even under thermal cycling and vibration conditions.

Corrosion Resistance

Sealed fin-to-tube interface prevents corrosive media penetration, extending service life in harsh environments.

Customizable Design

Available in various materials, fin densities, and configurations to meet specific application requirements.

Embedded Fined tube Industrial Applications

Embedded finned tubes are essential components across multiple industries where efficient heat transfer is critical:

Primary Applications

- Air Coolers and Heat Exchangers

- Air Heaters and Economizers

- Process Heaters and Boilers

- Condensers and Evaporators

Industry-Specific Applications

| Industry | Specific Applications | Key Benefits |

|---|---|---|

| Petroleum & Petrochemical | Crude oil heaters, catalytic reformers, hydrocrackers | High temperature resistance, corrosion protection |

| Natural Gas Processing | Gas sweetening units, LNG heat exchangers | Cryogenic temperature performance |

| Power Generation | Steam turbine condensers, feedwater heaters, HRSG | High pressure tolerance, thermal efficiency |

| Steel Industry | Blast furnace systems, converter cooling | Abrasion resistance, high temperature capability |

| HVAC & Refrigeration | Chillers, heat pumps, air conditioning systems | Compact design, efficient heat transfer |

| Waste Management | Waste incineration heat recovery | Corrosion resistance in aggressive environments |