How to classify finned tubes?

1. Classification of Finned Tubes by Manufacturing Process

The manufacturing method significantly impacts the thermal performance, mechanical strength, and application suitability of finned tubes. Understanding process-based classification helps engineers select optimal solutions for specific thermal challenges.

Extruded & Formed Finned Tubes

- Integral Rolled Finned Tubes: Created by cold-forming fins directly from the base tube material, ensuring excellent thermal conductivity and mechanical integrity. Ideal for high-pressure applications.

- Series of Pipe (Tube) Finned Tubes: Manufactured by extruding fins from the tube wall, providing uniform heat distribution and robust construction.

Attached Fin Technologies

- Tension Wound Finned Tubes: Metal strips are wound under tension into grooves machined into the base tube, creating strong mechanical bonds suitable for thermal cycling environments.

- Welded Fin Tubes:

- High-Frequency Welded Fins: Utilizes high-frequency current to create metallurgical bonds between fins and tubes, offering superior heat transfer efficiency.

- Submerged Arc Welded Fins: Provides deep penetration welding for heavy-duty applications in aggressive environments.

- Insert Tubes: Fins are mechanically inserted into prepared grooves, creating reliable thermal contact without welding.

Specialized Manufacturing Methods

- Cast Finned Tubes: Produced by casting fins directly onto the tube surface, creating complex geometries ideal for corrosive environments.

- Laser-Welded Finned Tubes: Advanced manufacturing providing precise control with minimal heat-affected zones for sensitive applications.

Technical Insight: The bond quality between fin and tube critically impacts thermal performance. Extruded fins offer the highest thermal efficiency, while welded fins provide the strongest mechanical attachment for demanding applications.

2. Classification by Fin Geometry and Configuration

Fin geometry directly influences heat transfer efficiency, pressure drop, fouling resistance, and mechanical stability. Selecting the appropriate fin shape is crucial for optimizing thermal system performance.

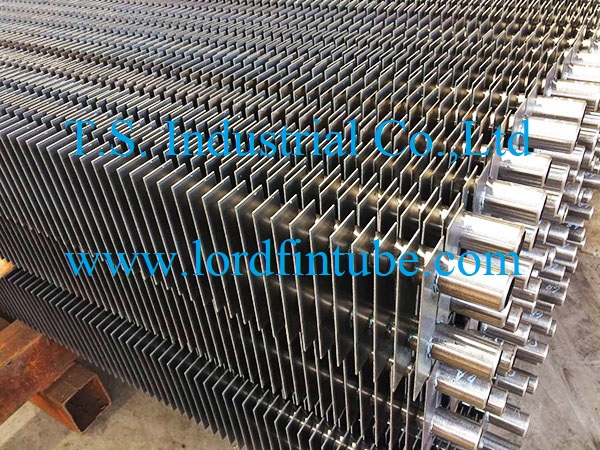

Double H Fin Pipe - An innovative finned tube design offering enhanced heat transfer surface area

| Fin Type | Heat Transfer Efficiency | Pressure Drop | Fouling Resistance | Typical Applications |

|---|---|---|---|---|

| Spiral Finned Tubes | High | Moderate | Good | Heat exchangers, boilers |

| Longitudinal Finned Tubes | Moderate | Low | Excellent | Air coolers, transformers |

| Serrated Finned Tubes | Very High | High | Poor | High-performance heat exchangers |

| Corrugated Fin Tubes | High | Moderate-High | Fair | Compact heat exchangers |

| Needle-shaped Fin Tubes | Extremely High | Very High | Poor | Specialized high-flux applications |

Advanced Fin Configurations

- Circular Finned Tubes: Provide uniform heat dissipation in all directions, ideal for air-cooled heat exchangers and HVAC systems.

- Integral Plate Fin Tubes (Ban Chi): Feature continuous plate-like fins offering maximum surface area for gas-to-liquid heat transfer.

- Square/Rectangular Finned Tubes: Optimized for specific spatial constraints in compact heat exchanger designs.

3. Material-Based Classification of Finned Tubes

Material selection determines corrosion resistance, thermal conductivity, temperature limits, and compatibility with process fluids. Understanding material properties is essential for durable finned tube applications.

High Thermal Conductivity Materials

- Copper Finned Tubes: Excellent thermal conductivity (400 W/m·K), superior corrosion resistance in clean environments. Ideal for HVAC, refrigeration, and low-temperature applications.

- Aluminum Finned Tubes: Lightweight with good thermal conductivity (240 W/m·K), cost-effective for air-cooling applications. Often used with carbon steel tubes in bimetallic configurations.

- Copper/Aluminum Composite Tubes: Combine coppers conductivity with aluminums lightweight properties and cost advantages.

High-Strength & Corrosion-Resistant Materials

- Carbon Steel Finned Tubes: Economical choice for high-temperature applications up to 400°C. Requires protective coatings in corrosive environments.

- Stainless Steel Finned Tubes: Excellent corrosion resistance and high-temperature capability. Types 304, 316, and 321 are common for aggressive chemical environments.

- Carbon Steel/Stainless Steel Combinations: Utilize stainless steel fins with carbon steel tubes for optimal cost-performance balance in moderately corrosive environments.

Specialized Material Solutions

- Cast Iron Finned Tubes: Exceptional corrosion resistance in specific chemical environments, though with lower thermal conductivity.

- Nickel Alloy Finned Tubes: For extreme temperature and corrosive service conditions in chemical processing and power generation.

- Titanium Finned Tubes: Superior corrosion resistance in seawater and chloride environments, used in marine and desalination applications.

4. Application-Specific Classification

Finned tubes are engineered for specific operational environments and performance requirements. Understanding application-based classification ensures optimal selection for thermal system design.

HVAC & Refrigeration

- Finned Tubes for Air Conditioning: Optimized for efficient heat transfer between refrigerant and air, typically using copper tubes with aluminum fins for maximum efficiency.

- Heat Pump Finned Tubes: Designed for reversible operation with robust construction to withstand thermal cycling and varying pressure conditions.

Power Generation & Industrial Processes

- Boiler Applications: Including water wall tubes, coal boiler economizers, and air preheaters utilizing specialized finned tubes for high-temperature flue gas heat recovery.

- Air Cooling Finned Tubes: Used in air-cooled heat exchangers for process cooling in power plants and refineries where water is scarce.

- Waste Heat Recovery Units: Designed to capture thermal energy from various kilns, furnaces, and process exhaust streams to improve overall system efficiency.

Specialized Industrial Applications

- Chemical Process Finned Tubes: Constructed from corrosion-resistant materials for aggressive chemical environments.

- Marine & Offshore Finned Tubes: Engineered with superior corrosion protection for seawater cooling applications.

- Cryogenic Finned Tubes: Specialized designs for low-temperature applications in LNG and industrial gas processing.

How to Select Finned Tube?

Finned tubes are critical heat transfer components used across numerous industries. This comprehensive guide explores the systematic classification of finned tubes based on manufacturing processes, geometric characteristics, material composition, and application-specific requirements. Proper classification of finned tubes enables engineers to systematically select the optimal design for specific thermal applications. Key considerations include:

- Thermal Performance Requirements: Match fin geometry and material to heat transfer coefficients and temperature differentials.

- Environmental Conditions: Select materials and manufacturing processes based on corrosion potential, fouling tendencies, and operational lifespan requirements.

- Mechanical Constraints: Consider pressure ratings, vibration resistance, and thermal expansion characteristics.

- Economic Factors: Balance initial cost against long-term performance, maintenance requirements, and energy efficiency.