Lord Fin Tube-Heat exchangers / economizers

Feed Water Preheaters and Economizers for Oil and Gas Fired Plants

Feed water preheaters and economizers are crucial components in oil and gas-fired power plants. They play a significant role in improving the overall efficiency of the power generation process by recovering waste heat from the flue gas and utilizing it to preheat the feed water before it enters the boiler.

Feed Water Preheaters:

Feed water preheaters are heat exchangers that raise the temperature of the water that is supplied to the boiler. The preheating process reduces the energy required to convert water into steam, resulting in fuel savings and increased overall plant efficiency. These preheaters typically utilize the waste heat from the flue gas leaving the boiler to heat the feed water.

There are different types of feed water preheaters commonly used in oil and gas-fired plants:

1. Shell and Tube Preheaters: This type of preheater consists of a series of tubes through which the feed water flows, surrounded by a shell through which the hot flue gas passes. Heat is transferred from the flue gas to the feed water through the tube walls, increasing the temperature of the water.

2. Plate-Type Preheaters: Plate-type preheaters utilize a stack of metal plates with alternating hot flue gas and feed water passages. Heat is transferred from the flue gas to the feed water as they pass through these parallel passages. Plate-type preheaters offer compact design and efficient heat transfer.

Economizers:

Economizers are another important heat recovery component in oil and gas-fired plants. They are typically installed in the flue gas path before it enters the chimney or stack. The primary function of an economizer is to recover heat from the flue gas and transfer it to the feed water, further increasing the temperature of the water before it enters the boiler.

Economizers can be of different types, including:

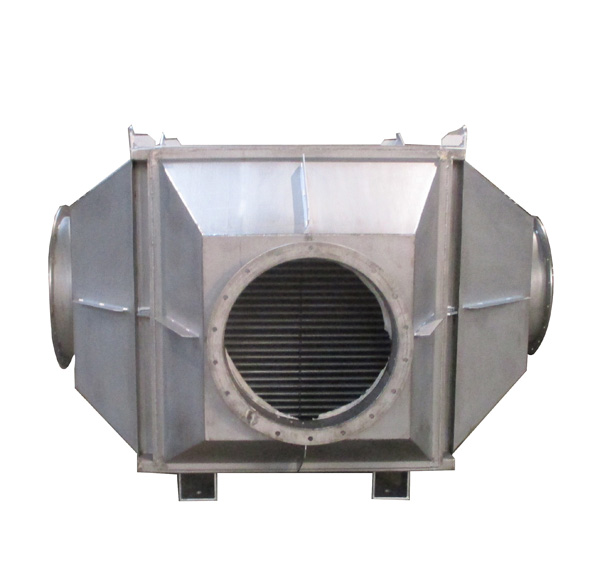

1. Bare Tube Economizers: Bare tube economizers consist of a series of tubes exposed to the hot flue gas. The feed water flows through these tubes, absorbing heat from the flue gas and raising its temperature.

2. Finned Tube Economizers: Finned tube economizers have extended surface area in the form of fins attached to the tubes. These fins increase the heat transfer area, enhancing the efficiency of heat transfer between the flue gas and feed water.

Benefits and Importance:

The incorporation of feed water preheaters and economizers in oil and gas-fired plants offers several benefits:

1. Improved Efficiency: By utilizing waste heat from the flue gas to preheat the feed water, the overall efficiency of the plant is enhanced. This leads to reduced fuel consumption, lower operating costs, and reduced greenhouse gas emissions.

2. Energy Conservation: The recovery of waste heat and its utilization for feed water preheating reduces the demand for primary fuel, resulting in energy conservation and a more sustainable operation.

3. Cost Savings: Improved efficiency and reduced fuel consumption translate into cost savings for the plant operator. The investment in preheaters and economizers can be recouped through lower fuel costs over the lifetime of the plant.

4. Environmental Impact: By maximizing the energy conversion efficiency, the use of feed water preheaters and economizers helps in reducing the environmental impact of oil and gas-fired plants. It contributes to lower emissions of greenhouse gases and other pollutants.

Feed water preheaters and economizers play a crucial role in enhancing the efficiency of oil and gas-fired power plants. By utilizing waste heat from the flue gas to preheat the feed water before it enters the boiler, these components contribute significantly to energy savings and cost reductions. Additionally, their operation helps in reducing the environmental impact of power generation by lowering fuel consumption and greenhouse gas emissions. Overall, integrating feed water preheaters and economizers into power plant systems is a smart investment for both economic and environmental reasons.