Standard ASTM A498 Heat-Exchanger Tubes with Integral Fins

ASTM A498 Standard Specification for Seamless and Welded Carbon Steel Heat-Exchanger Tubes with Integral Fins

1. Standard ASTM A498 Scope

1.1 This specification covers external helical, integral finned, seamless or welded low-carbon steel tubes for use in tubular heat exchangers, surface condensers, evaporators, superheaters, and similar heat-transfer apparatus in unfinned end diameters up to 2 in. [50 mm], inclusive.

1.2 Units—This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order

or contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently ofthe other. Combining values from the two systems may result in non-conformance with the standard.

2. Standard ASTM A498 Referenced Documents

2.1 ASTM Standards:

A179/A179M Specification for Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes

A214/A214M Specification for Electric-Resistance-Welded Carbon Steel Heat-Exchanger and Condenser Tubes

A334/A334M Specification for Seamless and Welded Carbon and Alloy-Steel Tubes for Low-Temperature Service

3. Standard ASTM A498 Ordering Information

3.1 The purchaser shall specify in the order the plain-tube specification and the alloy from which the finned tube is to be manufactured.

3.2 The purchaser shall specify in the order the diameter, wall thickness, and length of unfinned sections; root diameter and wall thickness ofthe finned section; number offins per unit length; and the total tube length.

4. Standard ASTM A498 Material and Manufacture

4.1 The finned tubes shall be manufactured from plain tubes that conform to one of the following Specifications: A179/A179M, A214/A214M, or A334/A334M.

4.2 Any tests that are required in the plain-tube specifications that are performed on unfinned lengths of tube in accordance with this specification need not be performed on the plain tube.

4.3 The fins shall be produced by the cold forming of steel prime-surface tube. To comply with this specification, the fin and tube material must be homogeneous.

4.4 Finned tubes shall normally be furnished with unfinned ends, but may be furnished with finned ends if specified.

5. Standard ASTM A498 Heat Treatment

5.1 The tube after finning shall be supplied in either the annealed or as-fabricated condition, one of which shall be specified on the purchaser order.

5.2 The annealed condition is defined as having both the finned and unfinned portions of the tube conforming to the applicable heat-treatment requirements of the governing ASTM specification for the steel tube analysis involved.

5.3 The as-fabricated condition is defined as having the finned portions of the tube in the as-finned or cold-worked condition produced by the finning operation and the unfinned or plain tube portions of the finned tube in the as-fabricated

condition suitable for rolling-in operations.

6. Standard ASTM A498 Chemical Composition

6.1 The steel shall conform to the chemical requirements prescribed in the governing plain-tube specification.

7. Standard ASTM A498 Tensile Requirements

7.1 The tube prior to the finning operation, or unfinned portions of the finned tube, shall conform to the requirements for tensile properties prescribed in the governing plain-tube specification.

8. Standard ASTM A498 Pressure Test

8.1 Each tube after finning shall be subjected to an internal air pressure of 250 psi [1.7 MPa] minimum for 5 s without showing evidence ofleakage. Any evidence ofleakage shall be cause for rejection. The test method used shall permit easy visual detection of any leakage, such as testing the tube under water or by the pressure differential method.

9. Standard ASTM A498 Dimensions and Permissible Variations

9.1 Diameter—The outside diameter of the unfinned sections shall not exceed the diameter tolerances as specified in the governing prime-surface tube specification (see Fig. 1).

9.2 Wall Thickness—No tube at its thinnest point beneath the fins or in the plain section shall be less than the minimum thickness specified.

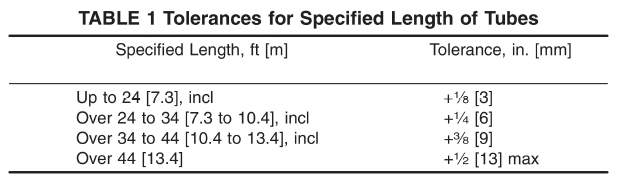

9.3 Length—The length of the tubes shall not be less than that specified when measured at a temperature of 68 °F [(20 °C], but may exceed the specified value by the amounts given in Table 1.

Integral Fins Tube Length Tolerance

10. Standard ASTM A498 Workmanship and Finish

10.1 Finished tubes shall be reasonably straight and have smooth ends free from burrs. They shall be free from injurious defects and shall have a workmanlike finish. Aslight amount of oxidation will not be considered as scale.

11. Standard ASTM A498 Package Marking

11.1 The name or brand of the manufacturer, name and order number of the purchaser, plain tube specification, condition (annealed or as-fabricated), Specification A498/A498M tube diameter, wall thickness, and tube length shall be marked on a tag securely attached to the bundle or box in which the tubes are shipped. The marking need not include the year of issue of the specification.

11.2 Bar Coding—In addition to the requirements stated in 11.1, bar coding is acceptable as a supplementary identification method. Bar coding should be consistent with the Automotive Industry Action Group (AIAG) standard prepared by the Primary Metals Subcommittee of the AIAG Bar Code Project Team.

12. Standard ASTM A498 Inspection

12.1 The inspector representing the purchaser shall have entry, at all times while work on the contract of the purchaser is being performed, to all parts of the manufacturer’s works that concern the manufacture of the material ordered. The manufacturer shall afford the inspector all reasonable facilities to satisfy him that the material is being furnished in accordance with this specification. All required tests and inspections shall be made at the place of manufacture prior to shipment, unless otherwise specified, and shall be conducted so as not to interfere unnecessarily with the operation of the works.

12.2 Certification—When specified in the purchase order or contract, the manufacturer shall furnish a dated report certifying that the material was manufactured, sampled, tested, and inspected in accordance with the requirements of this specification, including the year of issue of the specification.

13. Standard ASTM A498 Rejection

13.1 Any rejection based on tests made in accordance with this specification, and those allowed by the governing plain tube specification, shall be reported to the manufacturer. Disposition of rejected tubing shall be a matter of agreement between the manufacturer and the purchaser.

13.2 Material that fails in the process of installation shall be set aside and the manufacturer notified for mutual evaluation of suitability ofthe material. Disposition of such material shall be a matter for agreement.

14. Standard ASTM A498 Keywords

14.1 carbon steel tube; heat exchanger tube; seamless steel tube; steel tube; welded steel tube