Lord Fin Tube-L Type copper Fin Tube with Copper Fin

What are L Type Copper Fin Tubes with Copper Fins?

L Type copper fin tubes with copper fins represent advanced heat transfer technology designed for maximum thermal efficiency in demanding applications. These specialized components feature a unique "L" shaped mechanical bond configuration where both the base tube and extended fins are manufactured from high-grade copper, creating a seamless thermal transfer system.

The manufacturing process involves precision engineering where copper fins are mechanically embedded into the outer surface of copper tubes. This L-type bonding technique ensures superior thermal contact and structural integrity, eliminating the thermal resistance commonly found in other fin attachment methods.

L Type Copper Fin Tubes Technical Advantages

Exceptional Thermal Conductivity

Coppers superior thermal conductivity (401 W/m·K) ensures rapid heat transfer, making L Type copper fin tubes significantly more efficient than aluminum or steel alternatives.

Corrosion Resistance

Coppers natural corrosion resistance extends equipment lifespan, particularly in harsh environments with moisture, chemicals, or salt exposure.

Enhanced Surface Area

The L-shaped fin design increases effective heat transfer surface area by 300-500% compared to bare tubes, dramatically improving heat exchange efficiency.

Mechanical Durability

The mechanical bonding process creates permanent fin attachment that withstands thermal cycling, vibration, and mechanical stress without performance degradation.

Manufacturing Process and Quality Standards

The production of L Type copper fin tubes follows rigorous quality protocols. The process begins with high-purity copper tubes meeting ASTM B-75 specifications for seamless copper tube manufacturing. The fin material, typically C12200 DHP (Deoxidized High Phosphorus) copper, is selected for its optimal balance of thermal and mechanical properties.

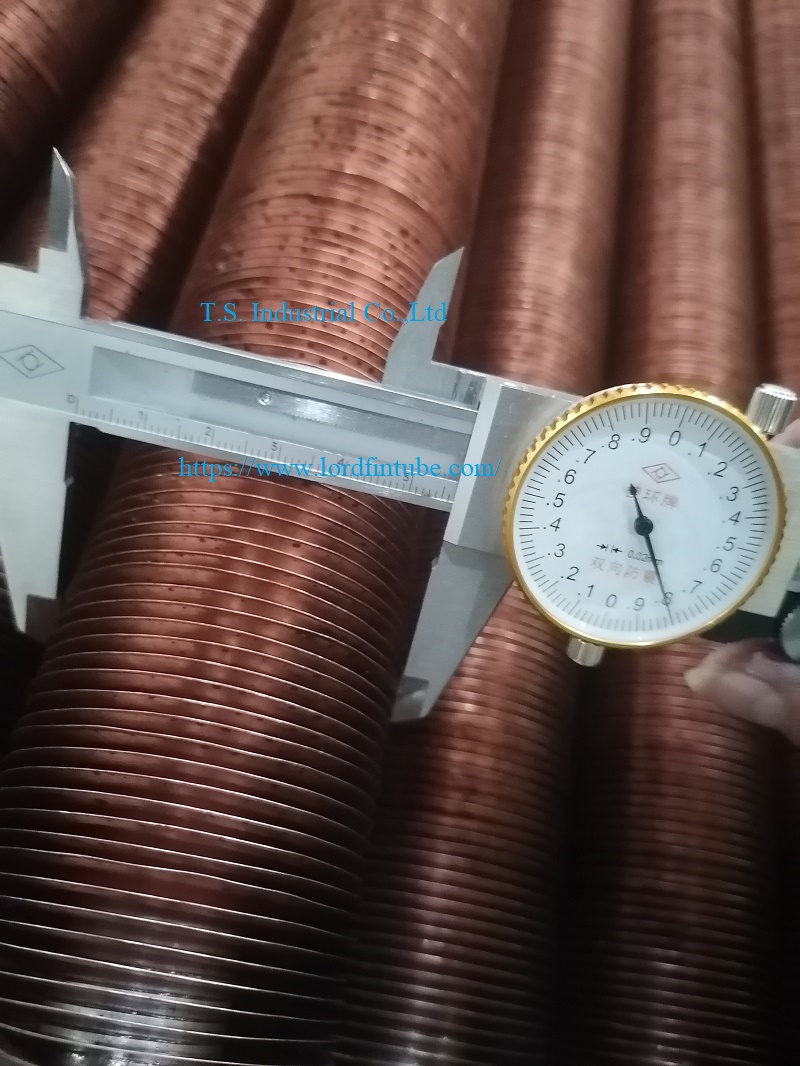

During manufacturing, precision machinery creates the L-shaped groove in the fin material, which is then wound under controlled tension onto the base tube. The mechanical interlock created ensures maximum contact pressure and thermal transfer efficiency. This process maintains the integrity of both materials without compromising their individual properties.

Technical Specifications and Standard Sizes

The following table details standard specifications for L Type copper fin tubes with copper fins, though custom configurations are available to meet specific application requirements:

| L Type Copper Fin Tubes with Copper Fins - Standard Specifications | ||||

|---|---|---|---|---|

| Parameter | Specification | Value | Parameter | Value |

| Base Tube Material | ASTM B-75 C12200 DHP | Tube O.D. (mm) | 16.3 | |

| Tube Thickness (mm) | 1.1 | |||

| Fin Material | Copper C12200 DHP | Fin Height (mm) | 10 | |

| Fin Thickness (mm) | 0.4 | |||

| Fin Pitch | 8 FPI | |||

| Fin Length (mm) | 1603 | |||

| Dimensions | Standard | Tube Length (mm) | 1703 | |

| Production | Batch Quantity | Fin Tube Quantity (Pc) | 350 | |

Note: ASTM B-75 establishes requirements for seamless round copper tubes suitable for general engineering applications, ensuring dimensional accuracy, mechanical properties, and surface quality.

L Type Copper Fin Tubes Industrial Applications

L Type copper fin tubes with copper fins serve critical roles across multiple industries where efficient heat transfer is essential:

- HVAC Systems: Air handling units, heat recovery systems, and specialized heating/cooling coils

- Refrigeration: Evaporators, condensers, and heat exchangers in commercial refrigeration systems

- Power Generation: Heat exchangers in turbine cooling systems and auxiliary cooling circuits

- Process Industries: Chemical processing heat exchangers, petroleum refining equipment

- Marine Applications: Sea water cooled heat exchangers and shipboard HVAC systems

- Renewable Energy: Geothermal heat exchange systems and solar thermal applications

- Industrial Machinery: Hydraulic oil coolers, compressor intercoolers, and transformer cooling

- Food Processing: Pasteurizers, sterilizers, and process cooling applications

L Type Copper Fin Tubes Performance Comparison and Selection

When selecting L Type copper fin tubes, engineers consider several critical factors:

Thermal Performance

Coppers exceptional thermal conductivity (approximately 60% higher than aluminum) makes L Type copper fin tubes the preferred choice for applications requiring maximum heat transfer efficiency. The all-copper construction eliminates bimetallic corrosion and ensures consistent thermal expansion characteristics.

Environmental Considerations

Coppers natural antimicrobial properties and recyclability make L Type copper fin tubes environmentally sustainable choices. Their long service life and 100% recyclability contribute to reduced environmental impact over the equipment lifecycle.

Cost-Benefit Analysis

While initial costs may be higher than alternative materials, the superior thermal performance, extended service life, and reduced maintenance requirements of L Type copper fin tubes with copper fins typically deliver superior lifetime value in demanding applications.

Maintenance and Operational Considerations

Proper maintenance of L Type copper fin tubes ensures long-term performance and reliability. Regular inspection for fin damage, cleaning to prevent fouling, and monitoring for corrosion are essential maintenance practices. The inherent corrosion resistance of copper reduces maintenance frequency compared to other materials, but specific environmental conditions may require protective coatings or specialized cleaning protocols.

Operational considerations include proper fluid velocity management to minimize erosion, appropriate chemical treatment of process fluids, and regular performance monitoring to detect efficiency degradation early.

L Type Copper Fin Tubes with Copper Fins

L Type copper fin tubes with copper fins represent the pinnacle of heat transfer technology, combining coppers exceptional thermal properties with innovative mechanical design. Their superior efficiency, durability, and reliability make them the optimal choice for demanding heat exchange applications across multiple industries.

The unique L-shaped configuration ensures maximum thermal contact and structural integrity, while the all-copper construction provides unmatched corrosion resistance and thermal performance. As industries continue to prioritize energy efficiency and equipment reliability, L Type copper fin tubes will remain essential components in advanced thermal management systems worldwide.