Lord Fin Tube-Laser welding finned tube

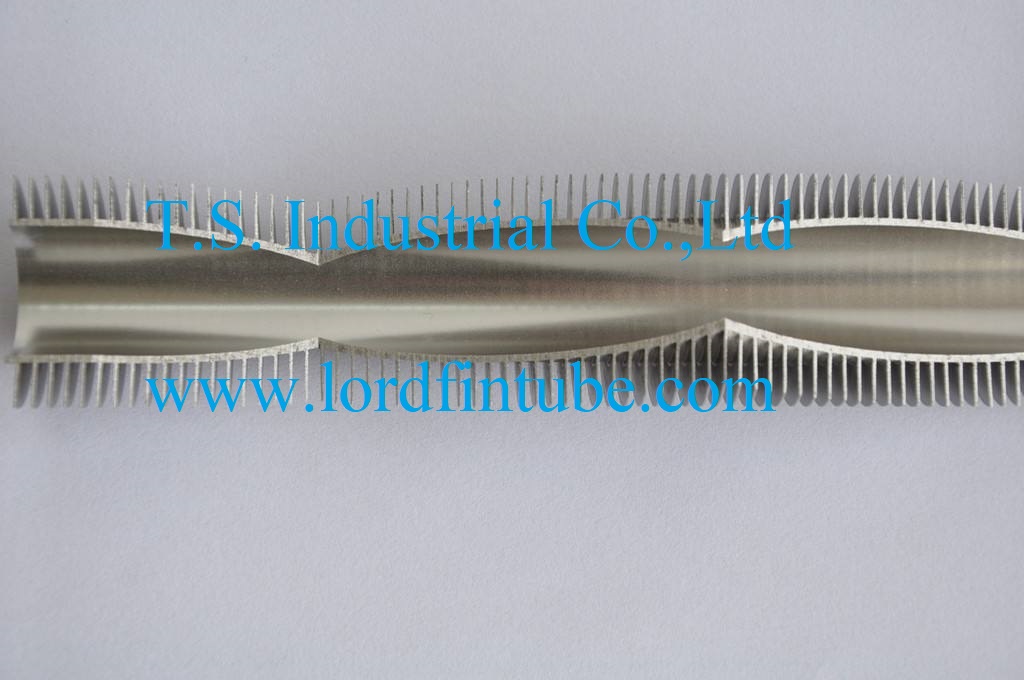

Our company has taken a significant leap in the field of heat exchange technology with the introduction and independent development of stainless steel laser-welded finned tubes. This cutting-edge product has revolutionized the industry by incorporating complete automation and mechanization into the welding process. The laser welding technique ensures a penetration depth of ≤ 0.2mm, leading to a substantial improvement in the heat transfer coefficient.

The technological superiority of our stainless steel laser-welded finned tubes surpasses that of traditional high-frequency welded fin tubes. The elimination of wrinkles, easy cleaning, and a remarkable reduction in material usage make it an upgraded and more efficient alternative. With a high welding rate and suitability for frequent cold and heat exchange, our product stands out as a reliable choice for diverse applications.

Laser Welding Finned Tube Features and Advantages:

1. Advanced Welding Technology: The laser welding process ensures precision and efficiency, resulting in a penetration depth of ≤ 0.2mm. This significantly enhances the heat transfer coefficient compared to traditional high-frequency welded fin tubes.

2. Increased Heat Dissipation Area: The fin distance can be ≤ 1.8mm, leading to a heat dissipation area more than 50% greater than that of traditional high-frequency welded fin tubes. This contributes to improved thermal performance.

3. Material Efficiency: With a fin thickness of ≤ 0.5mm, our finned tubes achieve over 50% reduction in material usage compared to traditional counterparts. This not only saves costs but also enhances product quality.

4. Compact Design: The reduced volume of combined equipment by two-thirds allows for more efficient and space-saving installations.

5. Stability and Reliability: The laser welding finned tube is a mature and stable product with proven technology. Its stable performance ensures reliability in various working conditions.

6. Versatility in Processing: Different materials can be used for processing, providing flexibility in meeting diverse application requirements.

7. Ease of Secondary Processing: The product allows for easy secondary processing, including coiling and bending, offering versatility in design and application.

8. Small Heat-Affected Zone: The welding heat-affected zone is minimal, enabling the processing of small-diameter finned tubes. This, in turn, opens up possibilities for a wider range of applications.

Our stainless steel finned tubes, primarily crafted from high-quality 304 stainless steel, find extensive use in heat exchange applications across industries such as power generation, petrochemical, HVAC, refrigeration, and air conditioning. The product excels in waste heat recovery and utilization, contributing to improved efficiency, extended product life, and significant material savings. The integral rolled fin tube design ensures no contact thermal resistance, exceptional heat transfer performance, high strength, heat resistance, and mechanical stability even in the face of vibrations. With six sets of laser welding machines and an impressive annual production capacity of 500,000 meters, we are committed to providing innovative and reliable solutions to meet the evolving needs of our customers.