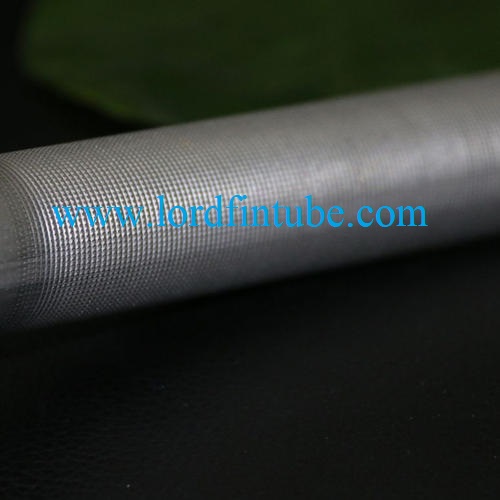

Lord Fin Tube--Low thread finned tube

1. Fabrication Principle of Low Thread Finned Tube:

A low-thread finned tube is a highly efficient heat transfer tube where thread-like fins are formed on the outer surface through rolling. The structure of this tube enhances heat transfer by increasing the heat transfer area with the fins. Additionally, when the medium flows over the threaded surface, the fins disrupt the laminar flow boundary layer, reducing its thickness and creating stronger turbulence compared to smooth tubes. This combined effect results in high heat transfer capacity. When used for evaporation, the increased surface area promotes bubble formation and improves boiling heat transfer. During condensation, the thread fins facilitate the dripping of condensate, reducing thermal resistance and enhancing heat transfer efficiency.

2. Features of Low Thread Finned Tube:

- Lower processing costs

- Wide application range

Low-thread finned tubes are suitable for various heat transfer applications, including evaporation, condensation, gas-to-gas heat transfer, and liquid flow heat transfer. As long as the shell-side medium is relatively clean without corrosion or scaling, low-thread finned tubes can be used in heat transfer components, creating efficient heat exchangers.

3. Definition of Low Thread Finned Tube:

A low-thread finned tube is a highly efficient heat exchange tube formed by rolling spiral fins onto the outer surface of a common heat exchange tube. Its strengthening effect is achieved externally. The screw fins increase the heat exchange area, and when the medium flows over the surface of the tube, the fins disrupt the laminar flow boundary layer, reducing its thickness. This design enhances heat transfer capacity by increasing bubble formation during evaporation and improving condensate dripping during condensation, resulting in reduced thermal resistance and improved heat transfer efficiency.

4. Additional Information about Copper Alloy Seamless High Finned Tube:

Copper and copper alloy seamless high finned tubes improve heat conduction performance and heat exchange efficiency by adding fins to the surface of the copper tubes, thereby increasing the heat exchange area. By utilizing the excellent heat conduction characteristics of copper, the fins enhance heat exchange efficiency, leading to high efficiency, energy savings, and material savings. Compared to smooth tube heat exchangers, finned tube heat exchangers offer advantages in thermal performance and economy. They can reduce the size of the heat exchanger by 30% to 75% under similar operating conditions. The application of finned tubes in chemical industries can address operational challenges in shell and tube heat exchangers and facilitate capacity expansion and efficient technological transformations. Continued research and application of finned tube heat exchangers are expected to grow in the future.