Introduction of stainless steel spiral finned tube

Introduction of stainless steel spiral finned tube

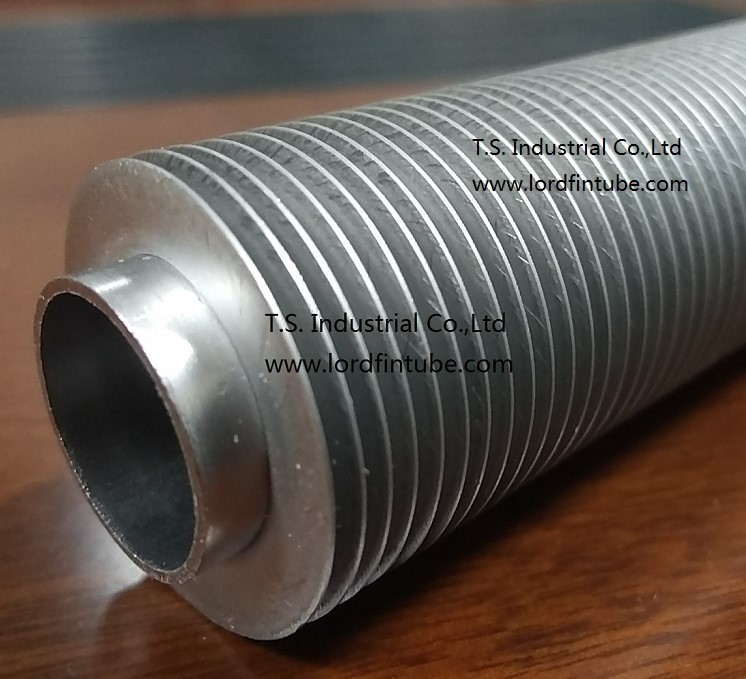

Stainless Steel Spiral finned tube is a type of heat transfer tube that is used in a variety of industrial applications. It is designed to increase the efficiency of heat transfer by increasing the surface area of the tube. The finned tube is made of stainless steel, which makes it resistant to corrosion, high temperatures, and high pressures.

One of the key features of Stainless Steel Spiral finned tube is its spiral shape. This shape allows for maximum heat transfer efficiency, as it increases the contact area between the fluid being heated or cooled and the surface of the tube. The spiral shape also helps to reduce the overall size of the tube, making it more compact and easier to install in tight spaces.

Another advantage of Stainless Steel Spiral finned tube is its resistance to corrosion. Stainless steel is a highly durable material that is able to withstand exposure to harsh chemicals and corrosive environments. This makes it an ideal choice for use in a wide range of industrial applications where corrosion resistance is essential.

Stainless Steel Spiral finned tube is also known for its high thermal conductivity. This means that it is able to transfer heat quickly and efficiently, making it an ideal choice for use in applications where rapid heat transfer is necessary. The finned tube design further enhances the heat transfer capabilities of the tube, making it an effective solution for a wide range of heating and cooling applications.

Overall, Stainless Steel Spiral finned tube is a versatile and highly effective solution for a wide range of industrial applications. Its unique design and durable construction make it an ideal choice for use in harsh environments where reliability and efficiency are essential.

The main types of stainless steel spiral finned tube

There are several types of spiral finned tubes available in the market, each designed for specific applications. Here are some of the common types of spiral finned tubes:

1. Solid Spiral Finned Tubes:

These are made from a single piece of metal and are the simplest type of spiral finned tube. They are often used in applications where the heat transfer requirements are not very high.

2. Serrated Spiral Finned Tubes:

These have a serrated surface, which increases the surface area and hence the heat transfer efficiency. They are commonly used in air-cooled heat exchangers.

3. Extruded Spiral Finned Tubes:

These are made by extruding fins from the parent metal tube. They have a high heat transfer coefficient and are often used in applications where there is a high temperature difference between the two fluids.

4. Wrap-On Spiral Finned Tubes:

These are made by wrapping a strip of metal around the parent tube and welding it to the tube. They have a high heat transfer coefficient and are commonly used in applications where there is a high gas flow rate.

5. Embedded Spiral Finned Tubes:

These have fins embedded in the surface of the parent tube, which increases the surface area and hence the heat transfer efficiency. They are often used in applications where the tube is subject to high mechanical stress.

Overall, the type of spiral finned tube selected for a particular application will depend on factors such as the required heat transfer efficiency, the operating conditions, and the level of mechanical stress the tube is expected to endure.

Stainless steel spiral finned tube

请输入搜索关键字

确定