What is finned stainless steel tubing?

Advanced Finned Stainless Steel Tubing for Industrial Heat Transfer Solutions

As a leading manufacturer of specialized heat transfer components, we provide comprehensive insights into finned stainless steel tubing technology. This guide combines engineering expertise with practical application knowledge to help engineers and procurement specialists make informed decisions.

Finned Stainless Steel Tubing

What is Finned Stainless Steel Tubing?

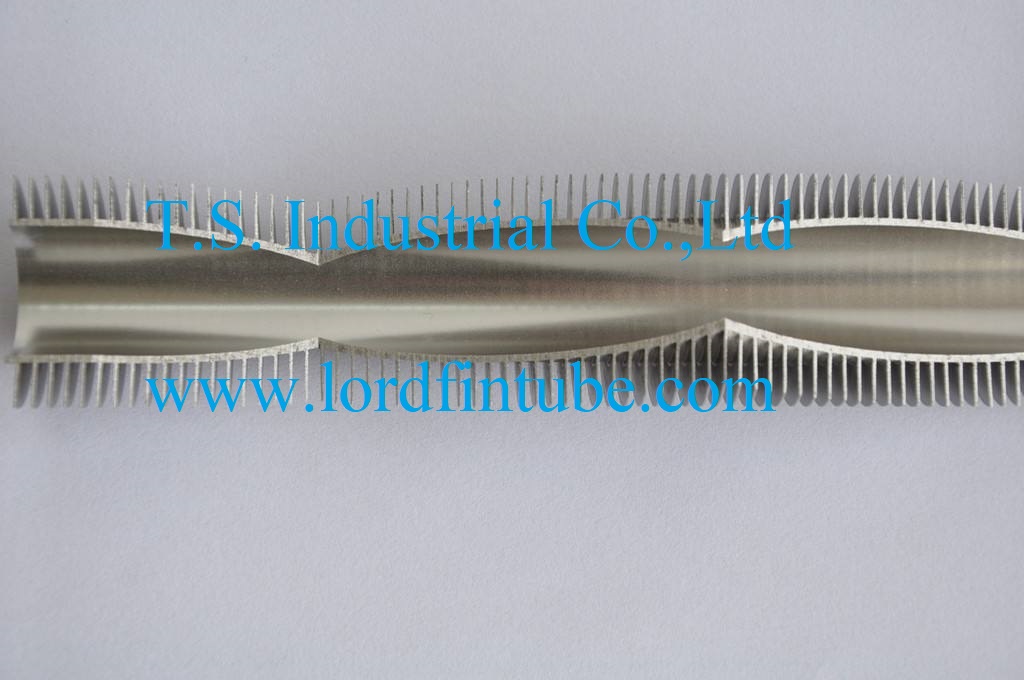

Finned stainless steel tubing represents an advanced thermal engineering solution where stainless steel tubes are enhanced with integrated fins to dramatically increase surface area and heat transfer efficiency. These precision-engineered components feature stainless steel strips welded onto the tubes external surface, creating a synergistic relationship between the core tubes structural integrity and the fins heat dissipation capabilities. This innovative design makes finned tubes indispensable in applications demanding optimal thermal performance within constrained spaces.

Finned Stainless Steel Tubing Manufacturing

Our manufacturing process integrates advanced welding technologies with precision engineering to produce reliable, high-performance finned tubing. The critical manufacturing aspects include:

- Stainless Steel Tube Selection: We begin with high-grade stainless steel tubes selected for their specific mechanical properties and corrosion resistance characteristics

- Precision Fin Attachment: Using advanced welding techniques, we securely bond fins to the tube surface while maintaining optimal thermal conductivity

- Quality Assurance: Every production batch undergoes rigorous testing for weld integrity, dimensional accuracy, and thermal performance

- Custom Engineering: We tailor fin density, height, and spacing to match specific application requirements and operating conditions

Finned Stainless Steel Tubing Grades

Selecting the appropriate stainless steel grade is crucial for optimal performance in specific environments. The following table details the characteristics and applications of different stainless steel grades used in finned tubing manufacturing:

| Grade | Key Characteristics | Primary Applications | Temperature Range |

|---|---|---|---|

| 304 Stainless Steel | Excellent corrosion resistance, formability, and weldability; most versatile grade | Food processing, chemical equipment, indoor heat exchangers | -200°C to 870°C |

| 316 Stainless Steel | Molybdenum-enhanced; superior chloride resistance; marine-grade quality | Marine environments, chemical processing, pharmaceutical equipment | -200°C to 870°C |

| 321 Stainless Steel | Titanium-stabilized; excellent intergranular corrosion resistance | Aerospace, exhaust systems, high-temperature chemical processing | -200°C to 900°C |

| 409 Stainless Steel | Good high-temperature oxidation resistance; cost-effective solution | Automotive exhaust systems, thermal oxidizers | -200°C to 815°C |

| 2205 Duplex | Combined austenitic-ferritic structure; high strength and corrosion resistance | Oil and gas, marine environments, chemical processing | -50°C to 300°C |

Finned Stainless Steel Tubing Applications

Heat Exchanger Systems

Enhancing efficiency in shell-and-tube and air-cooled heat exchangers for industrial processes and power generation facilities.

HVAC and Refrigeration

Improving heat transfer in air conditioning condensers, evaporators, and commercial refrigeration systems.

Chemical Processing

Maintaining precise temperature control in reactors, condensers, and heat recovery systems within chemical plants.

Power Generation

Optimizing heat transfer in boilers, condensers, and feedwater heaters for improved plant efficiency.

Oil and Gas Industry

Facilitating heat exchange in refining processes, gas compression cooling, and offshore platform systems.

Food and Beverage Processing

Ensuring hygienic heat transfer in pasteurization, sterilization, and process heating applications.

Finned Stainless Steel Tubing Selection

Choosing the right finned tubing requires consideration of multiple factors. The following comparison table helps engineers evaluate key parameters:

| Parameter | Standard Finned Tube | Enhanced Finned Tube | High-Performance Finned Tube |

|---|---|---|---|

| Fin Material | Carbon Steel | Aluminum/Stainless Steel | Special Alloys/Copper |

| Surface Area Increase | 8-12 times base tube | 12-20 times base tube | 20-30 times base tube |

| Thermal Efficiency | Good | Very Good | Excellent |

| Corrosion Resistance | Moderate | High | Exceptional |

| Typical Applications | General heating | Industrial processes | Critical systems |

| Cost Efficiency | High | Medium-High | Medium (considering lifecycle) |

Manufacturing Excellence in Finned Tubing Production

Our manufacturing facility specializes in producing custom finned stainless steel tubing solutions for demanding industrial applications. With over 15 years of experience in thermal engineering components, we combine advanced welding technologies with rigorous quality control measures to ensure every tube meets exacting specifications.

We offer comprehensive engineering support from design consultation through production and testing, ensuring optimal performance for your specific application requirements. Our technical team can assist with material selection, fin configuration optimization, and performance validation for both standard and custom finned tube designs.

Finned Stainless Steel Tubing Maintenance

Proper maintenance extends the service life and maintains the efficiency of finned stainless steel tubing installations. Key maintenance considerations include:

- Regular Inspection: Periodic visual examination for fin damage, corrosion, or fouling

- Cleaning Protocols: Appropriate cleaning methods based on operating environment and contaminants

- Performance Monitoring: Tracking heat transfer efficiency and pressure drop changes over time

- Corrosion Prevention: Implementing protective measures in aggressive environments

Technical Note: For applications involving extreme temperatures or corrosive media, consult with our engineering team for material recommendations and protective coating options. Proper material selection during the design phase can significantly extend component lifespan and reduce total cost of ownership.

Finned Stainless Steel Tubing Performance Factors

The performance of finned stainless steel tubing depends on several interrelated factors that engineers must consider during system design:

Fin Geometry: Fin height, thickness, and spacing directly impact heat transfer efficiency and pressure drop. Optimized fin geometry balances thermal performance with fluid dynamics considerations.

Material Compatibility: The thermal expansion coefficients of both tube and fin materials must be compatible to prevent stress-induced failure during temperature cycling.

Environmental Conditions: Operating environment dictates material selection, with factors including temperature extremes, corrosive elements, and mechanical stresses influencing design choices.

Manufacturing Quality: Weld integrity and dimensional accuracy directly impact thermal performance and long-term reliability in service.

For specific technical inquiries or custom finned tube requirements, our engineering team provides application-specific recommendations based on your operating parameters and performance expectations.