Products Description

What is studded pipe?

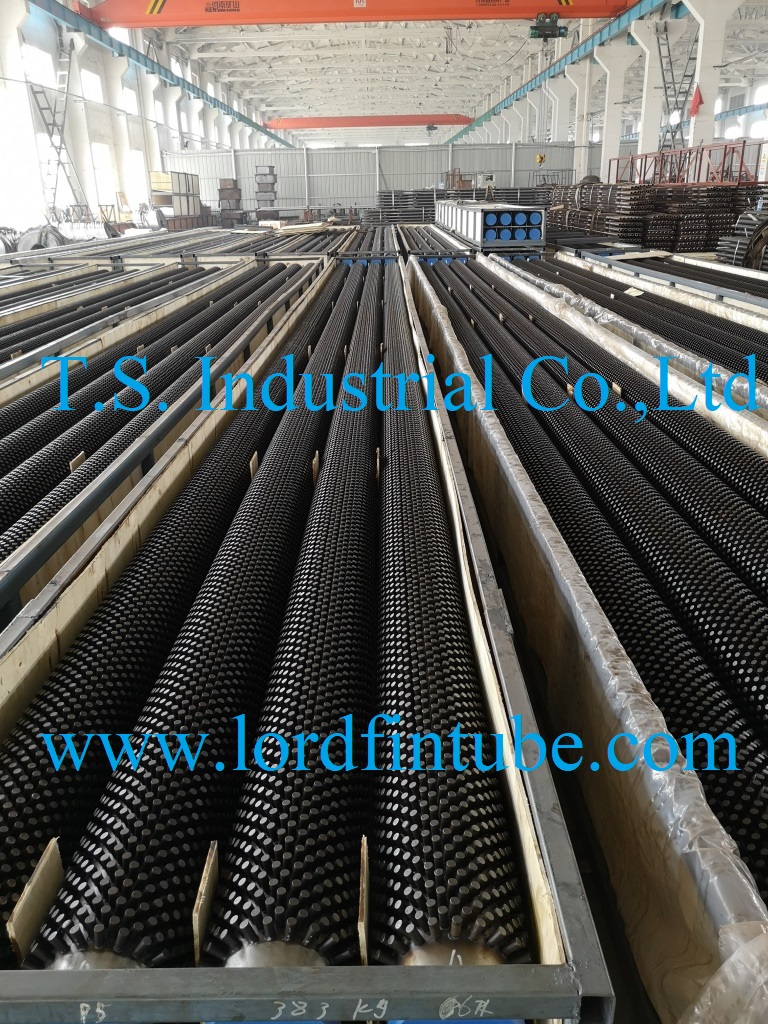

Studded Pipe also called studded tubes, Nailhead Pipe or stud Pipe. Studded pipes are used as an alternative to finned tubes in heat exchangers mainly in the petrochemical industry where the surface is exposed to particular corrosion and aggression by gasses and vapors. Studded fin tube is a standard frequency electric-resistance-welded studded type surface. Studded pipe normally weld round carbon steed studs on carbon, alloy or stainless steel tubes with diameters from 1.5" to 12.75".

How to produce studded pipe?

Studded pipe is made by electrical resistance stud welding equipment, which specially formed Studs in rows around the tube. The Studs can be supplied in a variety of sizes and shapes. The pattern in which the studs are arranged on the tube can also be varied by changing the Number of studs per row around the tube, the spacing between the rows, and whether the studs in adjacent Rows are offset. It is also possible to apply studs to just one side of the Tube, or to apply several different Height studs in the same row. The studs are hand loaded into the electrodes and then automatically welded. The welding process allows for the combination of any stud and tube grade, including carbon, alloy, stainless steels, and high nickel alloys. After studding, alloy steel pipes are stress-relieved in accordance with the relevant specifications for the steel class

Studded pipe advantages:

Because of their relatively thicker Cross-section as compared to fins, Studded pipe is one of the mechanically Strongest extended-surfaces Available. Although strength may not be a consideration for heat Transfer performance, it may be important when the application requires the extended surface to carry the weight of the tube at supports, or where severe mechanical abuse is expected in service or during cleaning.

Studded pipe usages:

The mainly applications for studded tubes is the process heat recovery of the petrochemical industry, in areas of convection ovens, vacuum generators for chemical processing, specially used in petroleum applications. Studded pipes high resistance in the harsh environments, such as sections of Sulfuric Acid atmospheres, makes it very useful for the industries mentioned.

Studded pipe size and material:

|

Tube O.D.: |

25~355.6 (mm) |

1”~14”(NPS) |

|

Tube Wall Thk.: |

3.5~28.6 (mm) |

0.14”~1.1” |

|

Tube Length: |

≤25,000 (mm) |

≤82 ft |

|

Stud Dia.: |

6~25.4 (mm) |

0.23”~1” |

|

Stud Height: |

10~50.8 (mm) |

0.4”~2” |

|

Stud Pitch: |

8~30 (mm) |

0.3”~1.2” |

|

Stud Shape: |

Cylindrical, Elliptical, Round, Lens type |

|

|

Stud to tube surface angle: |

Vertical, angular, staggered rows |

|

|

Stud Material: |

C.S. (most common grade is Q235B) S.S. (most common grade are AISI 304, 316, 409, 410, 321,347 ) A.S. |

|

|

Tube Material: |

C.S. (most common grade is A106 Gr.B) S.S. (most common grade are TP304, 316, 321, 347 ) A.S.(most common grade are T/P5,9,11,22,91 ) |

|

|

* This table is used as a general guide to our capabilities, please call us for any other customized cases. |

||

Stud Material: Carbon steel ASTM A510 grade 1005 to 1010. Alloy steels normally used in steel studs.

ASTM A193 Grade: B6, B6X, B8, B8a, B8M, B8C, etc. AISI 304, 316, 410, 347, 321

The studs are arranged in staggered rows (rings).

All tubes and studs material combination can be manufactured: Carbon, stainless, and alloy steels.

We can produce a large number of steel tube/stud combinations, including Carbon steel, Stainless steel and other steel alloys.

Stud tubes combinations comprised of different Carbon steel must receive heat treatment. We accomplish this on site, with our PWHT furnace

Studded Pipe, Studded Tube, Nailhead Pipe

Why use the studded pipe?

1. The heat exchange efficiency is equivalent to 2-3 times that of the bare pipe.

2. Easier cleaning especially for operating cases with very dirty flue gas produced by burning heavy oil, diesel or residual oil.

3. To increase the film heat transfer coefficient of flue gas to the furnace tube.

Increase efficiency in the process of heat recovery and direct flame hostile atmospheres.

4. Reduce the amount of bare pipes used in these processes. (Heat transfer surface of one studded pipe is equivalent to surface of 4 to 10 bare pipes). Studd Pipe’s ideal for processes applications where dirty fuels are used and harsh environments in terms of temperature and / or corrosion.

In order to forward you a promt offer for the finned tube, we would be pleased to receive you detailed enquiry including:

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)