Lord Fin Tube--Tips on boiler economizer

A boiler economizer is a critical heat exchanger device installed in the rear section of boiler flue gas systems. Its primary function is to recover waste heat from flue gases and transfer this thermal energy to preheat boiler feedwater before it enters the steam drum. This process occurs while the water is under pressure and approaching saturation temperature. By capturing this otherwise wasted heat, economizers significantly reduce flue gas exhaust temperatures, resulting in substantial energy savings and improved boiler efficiency.

Boiler economizers Working Principle

Boiler economizers operate on the counter-flow heat exchange principle, where relatively cool feedwater (typically 100-150°C) flows in the opposite direction to hot flue gases (250-400°C). This temperature differential creates optimal conditions for efficient heat transfer. The economizer raises the feedwater temperature closer to saturation point, reducing the energy required in the boiler to convert water to steam.

Boiler economizers Design

Process Understanding and Customization

Successful economizer implementation requires thorough understanding of specific operational parameters. Key factors influencing design include:

- Fuel Type Analysis: Different fuels (natural gas, oil, coal, biomass) produce varying flue gas compositions and temperatures

- Flue Gas Flow Dynamics: Accurate measurement of flow rates, temperatures, and pressure drops

- Feedwater Characteristics: Temperature, pressure, and chemical composition requirements

- Boiler Operating Conditions: Pressure ratings, steam capacity, and operational cycles

Advanced Heat Transfer Optimization

Modern economizer designs incorporate several efficiency-enhancing features:

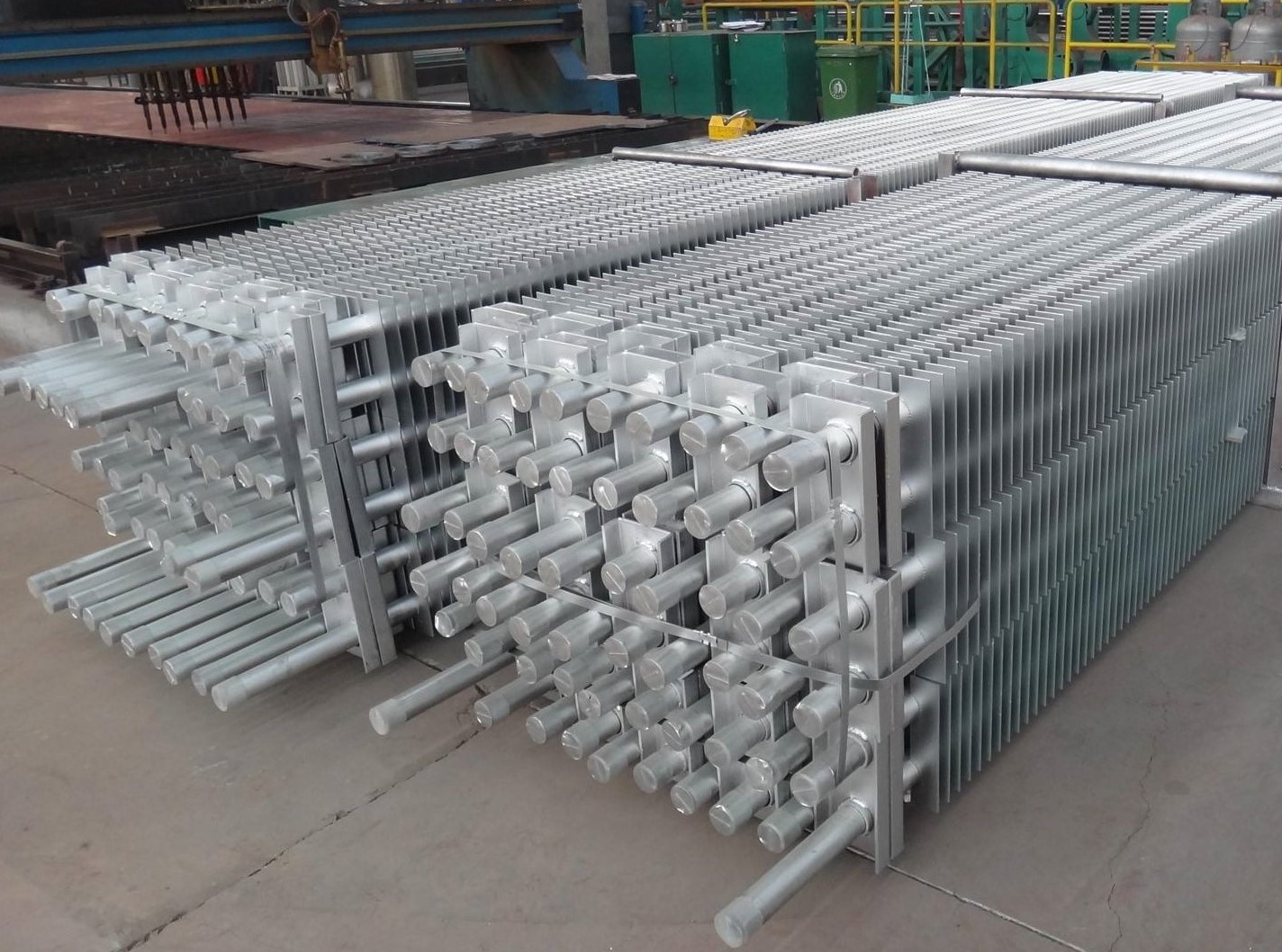

- Extended Surface Technology: Finned tube bundles dramatically increase heat transfer surface area

- Computational Fluid Dynamics: Advanced modeling optimizes flue gas and water flow paths

- Thermal Insulation Systems: High-performance materials minimize heat loss to surroundings

- Corrosion-Resistant Materials: Special alloys combat acid dew point corrosion

Advanced boiler economizer system showing heat exchange components and flow patterns

Boiler economizers Performance

Energy Recovery

Typically recovers 2-5% of boiler energy input by reducing flue gas temperatures by 20-50°C

Fuel Savings

Direct reduction in fuel consumption through improved thermal efficiency

Emissions Reduction

Lower fuel consumption directly correlates with reduced CO2 and NOx emissions

Operational Stability

Preheated feedwater reduces thermal stress on boiler components

Maintenance and Operational Best Practices

Preventive Maintenance Schedule

Regular maintenance is essential for sustained economizer performance:

- Soot and Ash Removal: Regular cleaning prevents buildup that impairs heat transfer

- Corrosion Inspection: Quarterly checks for tube degradation and pitting

- Performance Monitoring: Continuous tracking of temperature differentials and pressure drops

- Water Quality Management: Maintaining proper pH and oxygen levels to prevent internal corrosion

Advanced Monitoring and Control Systems

Modern economizers benefit from integrated sensor networks and control systems:

- Temperature sensors at inlet and outlet streams

- Pressure transducers monitoring differential pressure

- Flow meters tracking both flue gas and water flows

- Automated control valves adjusting water flow based on load conditions

- Data logging systems for performance trend analysis

Boiler economizers Perfomance Optimization

Continuous performance assessment ensures maximum efficiency and identifies maintenance needs:

- Thermal Efficiency Calculations: Regular computation of heat transfer effectiveness

- Pressure Drop Analysis: Monitoring increases that indicate fouling or blockage

- Energy Savings Quantification: Measuring actual fuel reduction and cost savings

- Predictive Maintenance Scheduling: Using performance data to plan maintenance activities

Boiler economizers Technical

When integrating a boiler economizer into existing systems, several critical factors must be addressed:

- Space Constraints: Economizers require adequate physical space in the flue gas path

- Material Compatibility: Selection of appropriate materials based on flue gas composition and temperature

- Water Chemistry: Proper treatment to prevent scale formation and corrosion

- Safety Systems: Incorporation of bypass dampers and protection systems

- Integration with Existing Controls: Seamless operation with boiler control systems

Boiler economizers

Boiler economizers represent one of the most cost-effective energy efficiency improvements available for steam generation systems. Through intelligent design, proper installation, and disciplined maintenance, these heat recovery devices typically achieve payback periods of 6-24 months while delivering substantial operational and environmental benefits. The continuous advancement in materials, fin tube technology, and control systems ensures that modern economizers remain a cornerstone of industrial energy conservation strategies.