Products Description

What is ASTM A213/ASME SA213 TP304 U bend tube?

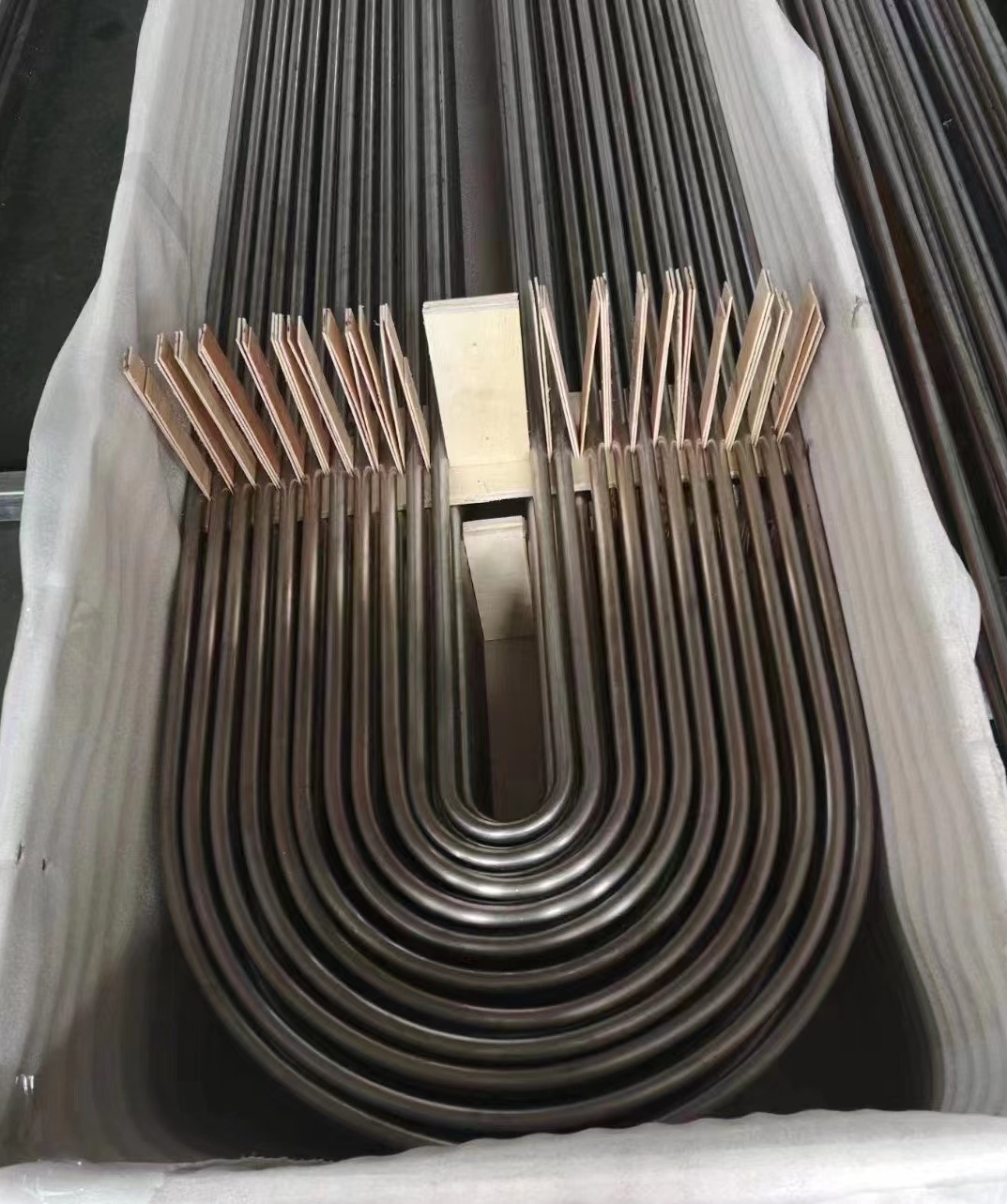

ASTM A213/ASME SA213 TP304 is a standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. U bend tubes are a specific type of tube that is used in heat exchangers, where the tube is bent into a U shape.

ASTM A213/ASME SA213 TP304 U bend tubes are made from TP304 stainless steel, which is an austenitic stainless steel that offers excellent corrosion resistance, high temperature resistance, and good mechanical properties. The U bend tubes are manufactured by cold bending the straight tubes using a special bending machine to achieve the desired U shape.

ASTM A213/ASME SA213 TP304 U bend tubes are commonly used in applications where heat needs to be transferred from one fluid to another, such as in boilers, heat exchangers, and condensers. They are available in various sizes and thicknesses to meet the specific requirements of different applications.

In addition to ASTM A213/ASME SA213 TP304, there are other materials and specifications that can be used for U bend tubes, depending on the specific application requirements. It is important to choose the right material and specification for the tube to ensure optimal performance and longevity.

How to test ASTM A213/ASME SA213 TP304 U bend tube?

ASTM A213/ASME SA213 TP304 U bend tubes are used in critical applications where they are exposed to high temperatures and pressures. Therefore, it is important to perform appropriate testing to ensure that the tubes meet the required standards and specifications. Here are some of the tests that can be performed on ASTM A213/ASME SA213 TP304 U bend tubes:

1. Hydrostatic Test: A hydrostatic test is a pressure test that is performed on U bend tubes to check for leaks and to ensure that the tube can withstand the required pressure. The test involves filling the tube with water and pressurizing it to a specified level for a specific duration.

2. Flaring Test: A flaring test is performed to check the ductility of the U bend tube. The test involves flaring the end of the tube to a specific diameter without cracking.

3. Hardness Test: A hardness test is performed to determine the hardness of the U bend tube. The test is usually performed using a Rockwell or Brinell hardness tester.

4. Tensile Test: A tensile test is performed to determine the tensile strength of the U bend tube. The test involves applying a tensile load to a specimen of the tube and measuring the amount of deformation.

5. Eddy Current Test: An eddy current test is performed to detect any surface or sub-surface defects in the U bend tube. The test involves passing an alternating current through a coil that generates an electromagnetic field. Any changes in the field caused by defects in the tube are detected and analyzed.

6. Dimensional Inspection: Dimensional inspection is performed to ensure that the U bend tube meets the required dimensions and tolerances specified in the standard.

These are some of the tests that can be performed on ASTM A213/ASME SA213 TP304 U bend tubes. It is important to follow the testing procedures specified in the standard to ensure accurate and reliable test results.

Does the U bend parts request heat treated?

Yes, U bend tubes made from ASTM A213/ASME SA213 TP304 stainless steel typically require heat treatment to achieve the desired mechanical properties and to reduce residual stresses that can lead to cracking and failure.

The heat treatment process usually involves heating the U bend tubes to a specified temperature, holding the temperature for a specific time, and then cooling the tubes at a controlled rate. The heat treatment process can vary depending on the specific requirements of the application and the standard or specification being used.

In the case of ASTM A213/ASME SA213 TP304 U bend tubes, the standard requires the tubes to be heat treated after bending. The heat treatment process is usually performed using a furnace or a heat-treating facility that is capable of meeting the specific requirements of the standard.

After heat treatment, the U bend tubes are typically subjected to various tests to ensure that they meet the required specifications and standards. These tests can include hydrostatic testing, flaring testing, hardness testing, and dimensional inspection, among others.

In summary, heat treatment is an important step in the manufacturing of U bend tubes made from ASTM A213/ASME SA213 TP304 stainless steel. It helps to achieve the desired mechanical properties and to reduce residual stresses that can lead to failure.