ASTM A213 TP316L stainless finned tube

ASTM A213 TP316L Stainless Finned Tubes

Premium corrosion-resistant heat transfer solutions for demanding industrial environments

Product Overview

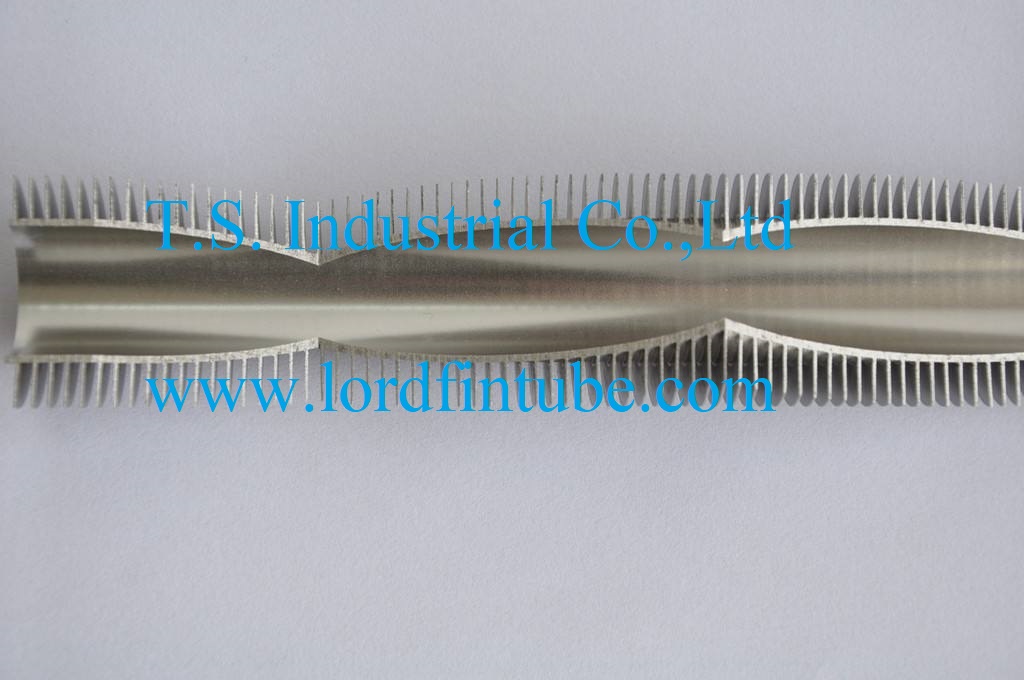

ASTM A213 TP316L stainless finned tube is a high-performance heat exchanger component manufactured from premium-grade 316L stainless steel. These tubes feature integral fins on their outer surface that significantly increase the heat transfer area, enhancing thermal efficiency in demanding industrial applications.

Technical Specification: The ASTM A213 standard covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. The TP316L designation refers to a low-carbon variant of 316 stainless steel, containing 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, offering superior corrosion resistance and weldability.

The finned tubes are available with either helical or straight fin configurations, selected based on specific application requirements and desired heat transfer characteristics. Helical fins provide maximum surface area in compact spaces, while straight fins offer lower pressure drop in high-flow applications.

Performance Advantages

Exceptional Corrosion Resistance

- Low-carbon (0.03% max) composition prevents sensitization

- 2-3% molybdenum enhances pitting and crevice corrosion resistance

- Excellent performance in acidic and chloride environments

- Resists oxidation at temperatures up to 870°C (1600°F)

- Ideal for seawater, chemical, and pharmaceutical applications

High-Temperature Capabilities

- Maintains strength at temperatures up to 925°C (1700°F)

- Excellent creep resistance under continuous operation

- Resistant to scaling and oxidation in steam environments

- Performs well in thermal cycling conditions

- Suitable for superheater and boiler applications

Strength and Durability

- High tensile strength: ≥485 MPa (70,000 psi)

- Excellent impact toughness at cryogenic temperatures

- Resistant to stress corrosion cracking

- Long service life with minimal maintenance

- Withstands mechanical and thermal shocks

Thermal Conductivity

16.3 W/m·K at 100°C, providing efficient heat transfer for energy-saving applications

Cost Efficiency

Optimal balance of performance and cost compared to specialty alloys

Fabrication

Excellent weldability and formability for complex installations

Hygienic Properties

Non-porous surface meets sanitary requirements for food and pharmaceutical industries

Technical Specifications

| Base Tube Material | ||||

| Fin Material | Tube Length (mm) | Fin length (mm) | Fin Tube Quantity (Pc) | Fin Material |

| ASTM A213 TP316L | SS316L | 9144 | 9040 | 740 |

| Base Tube O.D (mm) | Base Tube Thickness (mm) | Fin Height (mm) | Fin Thickness (mm) | Fin Pitch (mm) |

| 25.4 | 3.04 | 12.7 | 0.8 | 2.54 |

|

ASTM A213 Standard: Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes. TP316L composition: Cr 16-18%, Ni 10-14%, Mo 2-3%, C ≤0.03%, Mn ≤2.0%, Si ≤1.0%, P ≤0.045%, S ≤0.030%. Customization: Tubes can be manufactured in various diameters (15-50mm), wall thicknesses (1.5-5mm), fin heights (8-20mm), and fin pitches (2-8mm) to meet specific application requirements. |

||||

Corrosion Resistance Properties

Chemical Compatibility

Excellent resistance to a wide range of chemicals including organic acids, alkaline solutions, and chloride-containing environments. Performs exceptionally well in acetic acid, phosphoric acid, and dilute sulfuric acid applications.

Pitting Resistance

With a Pitting Resistance Equivalent Number (PREN) of 25-30, TP316L offers superior resistance to pitting corrosion in chloride environments, making it ideal for marine and coastal applications.

High-Temperature Corrosion

Maintains excellent oxidation resistance at temperatures up to 870°C (1600°F). The chromium content forms a protective oxide layer that prevents scaling in steam and combustion environments.

Material Science Insight: The addition of molybdenum (2-3%) in TP316L significantly enhances its resistance to pitting and crevice corrosion, particularly in chloride-containing environments. The low carbon content (≤0.03%) minimizes carbide precipitation during welding, maintaining corrosion resistance in heat-affected zones.

Industrial Applications

ASTM A213 TP316L stainless finned tubes are engineered for demanding heat transfer applications where corrosion resistance and reliability are paramount. They are designed to withstand harsh operating conditions and maintain peak performance over extended service periods.

Chemical Processing

Heat exchangers, reactors, and condensers handling corrosive media

Oil & Gas Refineries

Coolers, heaters, and condensers in offshore platforms

Pharmaceutical

Sterilizers, clean steam systems, and process heat exchangers

Food & Beverage

Pasteurizers, evaporators, and hygienic heat exchangers

Desalination Plants

Multi-stage flash and multi-effect distillation heat exchangers

Power Generation

Condensers, feedwater heaters, and boiler components

Energy Efficiency: The finned design increases heat transfer efficiency by up to 5 times compared to bare tubes, significantly reducing energy consumption. The excellent thermal conductivity of 316L stainless steel (16.3 W/m·K at 100°C) further enhances energy efficiency in heat recovery systems.

Quality Assurance: All TP316L finned tubes undergo rigorous testing including hydrostatic testing, eddy current examination, dimensional verification, and material certification. Our manufacturing process complies with ASME Section VIII and PED 2014/68/EU standards for pressure equipment.