Lord Fin Tube-Brass heat exchanger

What is brass heat exchanger?

A brass heat exchanger is a type of heat transfer device that utilizes brass as the primary material for constructing its heat exchange components. Brass, a copper-zinc alloy, is known for its excellent thermal conductivity, corrosion resistance, and mechanical strength, making it well-suited for heat exchanger applications.

The construction of a brass heat exchanger typically involves a series of brass tubes or plates that facilitate the transfer of heat between two fluids. The fluids can be of different temperatures, and the heat exchanger enables the transfer of thermal energy from the hot fluid to the cold fluid without mixing them.

Brass heat exchangers applications

Brass heat exchanger applications in various industries, including HVAC (heating, ventilation, and air conditioning), refrigeration, power generation, chemical processing, and industrial processes. Some common examples of brass heat exchangers include:

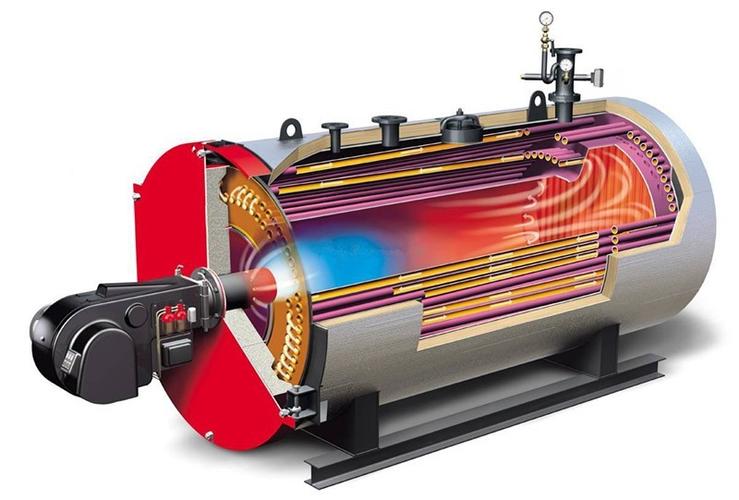

1. Shell and Tube Heat Exchangers: These heat exchangers consist of a shell (outer casing) that contains a bundle of brass tubes. One fluid flows through the tubes, while the other fluid flows around the tubes in the shell, facilitating heat transfer.

2. Plate Heat Exchangers: Plate heat exchangers use a series of brass plates with alternating channels to create flow paths for the two fluids. The plates are stacked together, allowing for efficient heat transfer through a large surface area.

3. Finned Tube Heat Exchangers: Finned tube heat exchangers employ brass tubes with integral fins attached to the outer surface. The fins increase the heat transfer area, enhancing the overall heat exchange efficiency between the fluids.

The choice of a brass heat exchanger offers several advantages:

1. Excellent Thermal Conductivity: Brass has good thermal conductivity, allowing for efficient heat transfer between the fluids. This results in effective heat exchange and optimal energy utilization.

2. Corrosion Resistance: Brass exhibits excellent resistance to corrosion, making it suitable for handling various fluids, including water, oils, and certain chemicals. It offers durability and reliability in demanding environments.

3. Mechanical Strength: Brass provides good mechanical strength, allowing the heat exchanger to withstand high pressures and temperature differentials without deformation or failure.

4. Ease of Fabrication: Brass is relatively easy to fabricate, enabling the production of complex heat exchanger designs and customization based on specific requirements.

However, it is important to note that brass may not be suitable for applications involving highly corrosive environments or certain fluids, such as acids or alkalis, which may cause accelerated corrosion. In such cases, alternative materials with higher corrosion resistance may be considered.

In summary, a brass heat exchanger is a reliable and efficient solution for heat transfer applications, offering excellent thermal conductivity, corrosion resistance, and mechanical strength. Its versatility and wide range of configurations make it a popular choice across various industries.