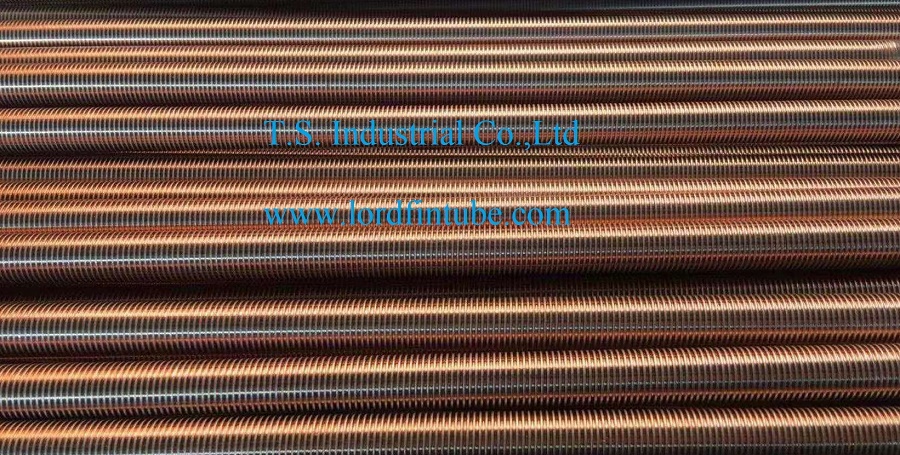

C71500 copper-nickel finned tubes

Copper Nickel tubes CuNi 70/30 30% or C71500 has the best resistance to acids corrosion compare with any other copper alloy tube. C71500 is used in harsh corrosive environments where longer service lives than those of other copper alloys are desired.

C71500 copper-nickel finned tubes is intergrally extexded for the maximum surface area to achieve high tube efficiency. Good C71500 copper-nickel finned tubes can be made by the strict conditions such as copper density, grain size and hardness. The heat transfer ratio of this high finned tube is about 8~9 times higher than other plain copper tube.

|

UNS No. |

C71500 – BSI No. CN107 – ISO Name CuNi30Mn1Fe |

|

Chemical Comp. (%) |

Cu rem / Ni 29 ~ 33 / Pb 0.05 / Fe 0.40 ~ 1 / Zn 1 max |

|

ASTM Spec. |

B 111, B 359, B395, B 466, B 467, B 543, B 552 |

|

ASME Spec. |

SB 111, SB 395, SB 466 |

|

Applications |

Condenser, Evaporator and Heat Exchanger tubes; Distiller tubing; Salt Water piping. |

|

Temper |

O61 Annealed / HR50 Drawn & Stress Relieved |

At present, there are many grades of copper and copper alloy finned tube products. The most difficult grade to be recognized is C71500 copper-nickel finned tube, because it contains nickel and Iron. According to the characteristics of nickel and ferrous metals, The torsion and pressure of rolling rotation are large during fabricate the finning.

|

Properties * |

Metric |

Imperial |

|

Density |

8.94 g/cc |

0.323 lb/in³ |

|

Tensile Strength min.- O61 -/- HR50 |

360 MPa -/- 495 MPa |

52 ksi -/- 72 ksi |

|

Yield Strength min.- O61 -/- HR50 |

125 MPa -/- 345 MPa |

18 ksi -/- 50 ksi |

|

CTE, linear |

16.2 10-6/°C @ 20.0 – 300 °C |

9.0 10-6/°F @ 70.0 – 570 °F |

|

Specific Heat Capacity |

0.09 cal/g-°C @ 20ºC |

0.09 BTU/lb-°F @ 70ºF |

|

Thermal Conductivity |

29 W/m-K @ 20.0 °C |

17 BTU/ft2/ft/h/°F @ 70.0 °F |

|

Melting Point |

1171 – 1238 °C |

2140 – 2260 °F |