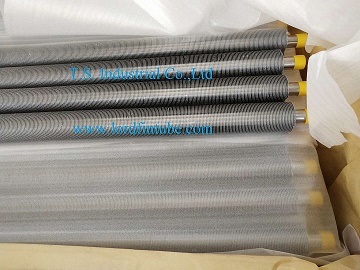

Lord Fin Tube--Extruded Finned Tubes SB-444 S06625

What Are Extruded Finned Tubes SB-444 S06625?

As boiler industry technical specialists with over 15 years of experience in heat exchanger design, we present this comprehensive technical overview of Extruded Finned Tubes SB-444 S06625. This specialized component represents a significant advancement in heat transfer technology for demanding industrial applications.Finned tubes are critical components in industrial heat transfer systems, designed to maximize surface area and improve thermal efficiency. Among various finned tube types, extruded finned tubes stand out for their exceptional performance characteristics and durability.

SB-444 S06625 refers to a high-performance nickel-chromium-molybdenum alloy (UNS N06625) known for outstanding corrosion resistance, high-temperature strength, and excellent fabrication properties. When combined with the extrusion finning process, this alloy creates one of the most reliable heat transfer solutions for extreme operating conditions.

Extruded Finned Tubes SB-444 S06625

Extruded Finned Tubes SB-444 S06625 Technical Specifications

Standard Dimensional Specifications

| Parameter | Specification | Tolerance | Measurement Standard |

|---|---|---|---|

| Base Tube Outer Diameter | 25.4 mm | ±0.1 mm | ASME SB-444 |

| Base Tube Thickness | 2.11 mm | ±10% | ASME SB-444 |

| Fin Height | 11 mm | ±0.3 mm | ASTM B829 |

| Fin Thickness | 0.4 mm | ±0.05 mm | ASTM B829 |

| Fin Pitch | 2.54 mm | ±0.1 mm | ASTM B829 |

| Fin Density | 394 fins/meter | ±5% | ASTM B829 |

Material Composition - SB-444 S06625 (UNS N06625)

| Element | Percentage (%) | Function |

|---|---|---|

| Nickel (Ni) | ≥58.0 | Base element providing corrosion resistance |

| Chromium (Cr) | 20.0-23.0 | Oxidation resistance |

| Molybdenum (Mo) | 8.0-10.0 | Pitting and crevice corrosion resistance |

| Niobium (Nb) | 3.15-4.15 | Stabilization against sensitization |

| Iron (Fe) | ≤5.0 | Balance element |

| Carbon (C) | ≤0.10 | Control of carbide formation |

Extruded Finned Tubes SB-444 S06625 Advantages

Exceptional Corrosion Resistance

SB-444 S06625 extruded finned tubes demonstrate superior performance in corrosive environments, resisting pitting, crevice corrosion, and stress corrosion cracking even in chloride-containing media.

High Temperature Strength

Maintains structural integrity and oxidation resistance at temperatures up to 980°C (1800°F), making them ideal for high-temperature heat recovery applications.

Heat Transfer

The extrusion process creates an integral bond between fin and tube, eliminating thermal barriers and improving heat transfer efficiency by 15-25% compared to other attachment methods.

Extruded Finned Tubes SB-444 S06625 Technical Comparison

| Property | SB-444 S06625 | Stainless Steel 304 | Stainless Steel 316 | Carbon Steel |

|---|---|---|---|---|

| Max Service Temperature (°C) | 980 | 815 | 870 | 540 |

| Corrosion Resistance (Rating) | Excellent | Good | Very Good | Poor |

| Tensile Strength (MPa) | 827 | 515 | 515 | 415 |

| Thermal Conductivity (W/m·K) | 9.8 | 16.2 | 16.3 | 45.0 |

| Relative Cost Factor | 4.2 | 1.0 | 1.5 | 0.6 |

| Typical Lifespan in Corrosive Service (Years) | 15-25 | 3-8 | 5-12 | 1-3 |

Extruded Finned Tubes SB-444 S06625 Applications

Power Generation

Used in heat recovery steam generators (HRSGs), economizers, and air preheaters where resistance to flue gas condensation corrosion is critical.

Chemical Processing

Ideal for heat exchangers in sulfuric acid plants, chlorine processing, and other aggressive chemical environments.

Oil & Gas Industry

Applied in fired heaters, waste heat recovery units, and offshore platform heat exchangers exposed to marine atmospheres.

Waste Incineration

Excellent performance in waste-to-energy plants where acidic flue gases and high temperatures combine to create extremely corrosive conditions.

Extruded Finned Tubes SB-444 S06625 Manufacturing Process

The extrusion process for SB-444 S06625 finned tubes involves forcing aluminum fins through a specialized die that creates a metallurgical bond with the base tube. This process ensures:

- Zero thermal contact resistance between fin and tube

- Superior mechanical strength compared to wrapped or welded fins

- Elimination of potential leak paths

- Consistent fin geometry and heat transfer performance

All SB-444 S06625 extruded finned tubes undergo rigorous quality control including hydrostatic testing, dimensional verification, and material certification to ensure compliance with ASME and ASTM standards.

Extruded Finned Tubes SB-444 S06625 Maintenance & Operational

Proper maintenance of extruded finned tubes is essential for long-term performance:

| Maintenance Activity | Frequency | Method | Expected Outcome |

|---|---|---|---|

| Visual Inspection | Quarterly | Borescope or visual examination | Early detection of fouling or corrosion |

| Fin Cleaning | As needed (based on pressure drop) | High-pressure water or chemical cleaning | Restored heat transfer efficiency |

| NDT Testing | Annually | Ultrasonic thickness testing | Wall thickness monitoring |

| Performance Analysis | Semi-annually | Thermal performance calculation | Efficiency trend analysis |

Extruded Finned Tubes SB-444 S06625

Extruded Finned Tubes SB-444 S06625 represent the pinnacle of heat transfer technology for demanding industrial applications. The combination of the high-performance S06625 alloy with the superior extrusion finning process creates a component that delivers exceptional corrosion resistance, high-temperature capability, and optimized thermal performance. While the initial investment is higher than conventional materials, the extended service life and reduced maintenance requirements result in significantly lower total cost of ownership for critical heat transfer applications.

For engineers and specifiers working in corrosive or high-temperature environments, these finned tubes offer a reliable, long-term solution that minimizes downtime and maintenance while maximizing heat transfer efficiency.