G-type finned tubes and KL finned tubes comparation

G-type finned tubes and KL finned tubes, which is better?

Its difficult to say which type of finned tube, G-type or KL, is definitively better, as both have advantages and disadvantages depending on the specific application and operating conditions.

The choice between G-type finned tubes and KL finned tubes depends on specific application requirements, operating conditions, and other factors. Both types of finned tubes are used for enhancing heat transfer in various industrial processes.

1. G-type Finned Tubes:

- Design: G-type fins have a distinctive shape resembling the letter "G." These fins are typically helical (spiral) and wound around the tube.

- Advantages:

- The helical design provides good heat transfer efficiency.

- Suitable for a wide range of applications.

- Can handle high temperatures and pressures.

- Applications: G-type finned tubes are commonly used in air-cooled heat exchangers, boilers, and other industrial processes.

2. KL Finned Tubes:

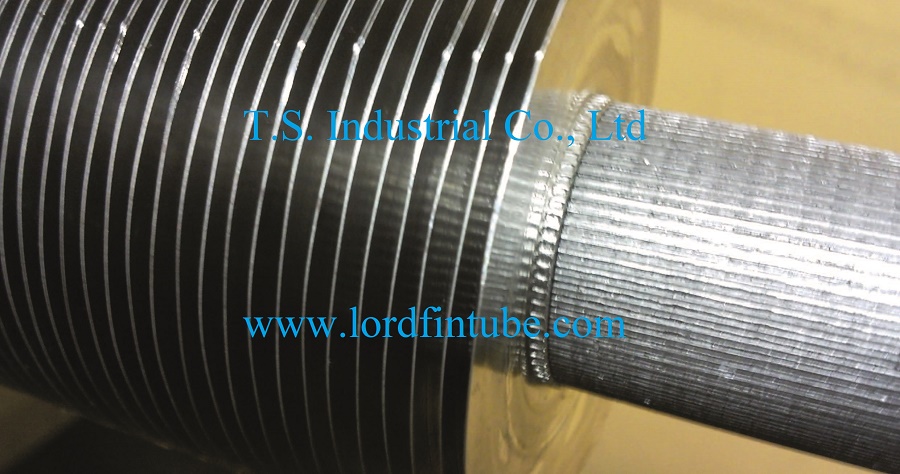

- Design: KL fins are usually formed by wrapping a thin strip of metal around the tube in a helical pattern, creating a series of interconnected "K" and "L" shapes.

- Advantages:

- Offers high thermal performance.

- Efficient in heat recovery applications.

- Suitable for corrosive environments.

- Applications: KL finned tubes are often used in applications where corrosion resistance and high thermal efficiency are crucial, such as in the petrochemical industry.

Choosing between G-type and KL finned tubes:

- Operating Conditions: Consider the temperature, pressure, and corrosiveness of the operating environment. KL finned tubes might be preferred in corrosive environments, while G-type fins may be suitable for higher temperature and pressure applications.

- Heat Transfer Efficiency: Both types offer good heat transfer efficiency, but the specific requirements of your application may influence the choice. KL fins are known for their high thermal performance.

- Application Specifics: The type of industry and specific heat exchange requirements play a role. For example, G-type fins are widely used in air-cooled heat exchangers, while KL fins might be chosen for applications in the chemical or petrochemical industry.

- Cost Considerations: Cost can also be a factor. Evaluate the cost of manufacturing, installation, and maintenance for each type.

Its essential to consult with engineers or experts in heat transfer and finned tube applications to determine the best choice based on your specific needs and operating conditions. Additionally, considering factors such as material compatibility and ease of maintenance can help in making an informed decision.

For example, G-type finned tubes are typically better suited for gas-to-fluid heat transfer applications due to their larger fin pitch and mechanical strength, whereas KL finned tubes may be more effective in liquid-to-fluid heat transfer applications due to their smaller fin pitch and higher heat transfer coefficient. Additionally, the choice of finned tube may also depend on other factors such as cost, ease of manufacturing, and availability of materials. Ultimately, the most suitable type of finned tube for a given application will depend on a thorough analysis of the specific requirements and operating conditions, taking into account factors such as heat transfer performance, mechanical strength, and durability.

KL finned tubes