What is the Heat Affected Zone (HAZ) in finned tubes?

2024-03-23Leave a message

What constitutes the Heat Affected Zone (HAZ)?

The Heat Affected Zone (HAZ) refers to the region in a metal where melting hasnt occurred, yet its properties have been altered due to exposure to elevated temperatures during welding. Situated between the weld and the unaffected base metal, the HAZ experiences changes in its characteristics.

The breadth of the Heat Affected Zone (HAZ) is contingent upon the quantity of heat absorbed by the material, which correlates with the heat input of the welding process. Additionally, the size of the HAZ is affected by thermal diffusivity. Materials with higher thermal diffusivity can disperse heat more rapidly, resulting in faster cooling for a given heat input, thus leading to a narrower HAZ. Notably, copper exhibits significantly greater thermal diffusivity compared to steel. Consequently, under equivalent heat input conditions, the HAZ of copper would be narrower than that of steel.

Heat Affected Zone (HAZ) Areas

Within the vicinity of the weld or cutting area and the adjacent unaffected parent metal, the Heat Affected Zone (HAZ) comprises distinct regions delineated by their proximity to the applied welding or cutting heat.

At the core lies the weld or cutting zone, where the material transitions into a liquid state during the process, bordered by the fusion boundary. This boundary marks the interface between the molten and solid phases of the metal. Adjacent to this zone is the HAZ proper, where the unaltered parent metal undergoes microstructural changes. In traditional steel compositions, the HAZ can be categorized into the grain coarsened zone (nearest to the heat source), the grain refined zone, the partially transformed (intercritically heated) zone, and the tempered zone. Conversely, in materials lacking solid-state phase transformation upon cooling, distinct zones such as grain growth and recrystallization may be observed, often accompanied by signs of tempering. Beyond these delineated HAZ regions lies the unaffected base material.

These varied HAZ regions arise from the differential temperatures experienced by the base metal farther away from the welding or cutting source. It is crucial to distinguish these zones from the visible colored bands, attributed to surface oxidation, often observed near stainless steel welds. Termed "temper colors," these bands signify substantially lower temperatures compared to those responsible for forming the heat affected zone, extending some distance beyond its boundaries. These colors, also referred to as heat tints, provide an approximate gauge of the metals attained temperature. For instance, in the case of stainless steel type 1.4301 (AISI 304) subjected to open-air heating, the band colors and corresponding temperatures are as follows:

- Light yellow: 290°C / 550°F

- Straw yellow: 340°C / 640°F

- Yellow: 370°C / 700°F

- Brown: 390°C / 735°F

- Purple brown: 420°C / 790°F

- Dark purple: 450°C / 840°F

- Blue: 540°C / 1000°F

- Dark blue: 600°C / 1110°F

The hues of heat tint colors depend on the metals oxidation resistance, with higher chromium content metals displaying less intense coloration due to their enhanced resistance to oxidation. The utilization of protective gases and electrode coatings can mitigate heat tint by partially shielding the metal from oxidation. Conversely, rougher surfaces tend to oxidize more rapidly, resulting in darker hues. Additionally, substances such as paint, oil, rust, and fingerprints can influence heat tint colors, albeit without impacting the extent of the HAZ itself.

Heat Affected Zone (HAZ) in high-frequency welded finned tubes

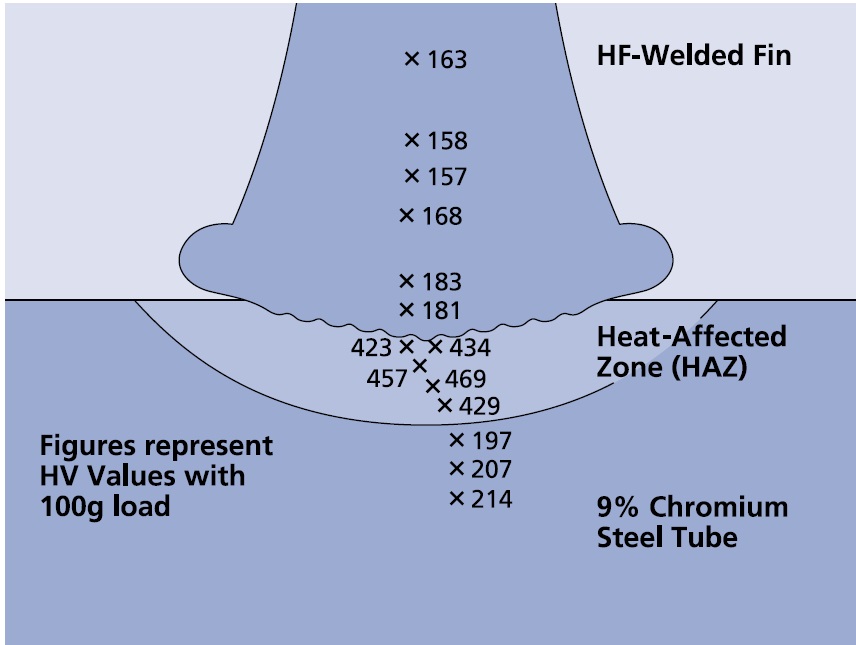

In high-frequency welded finned tubes, the Heat Affected Zone (HAZ) refers to the region surrounding the weld seam where the base tube and fins have been subjected to elevated temperatures during the welding process.

During high-frequency welding, the localized application of high-frequency electrical currents generates heat at the weld interface, causing the metal in the vicinity to soften. Although the temperatures in the HAZ are not as high as those in the fusion zone where melting occurs, they are sufficient to induce metallurgical changes in the base tube and fins.

The HAZ in high-frequency welded finned tubes typically experiences alterations in its microstructure and mechanical properties due to the thermal input during welding. These changes can include grain growth, tempering, and the formation of residual stresses. The extent and characteristics of the HAZ depend on various factors, including welding parameters, material composition, and heat dissipation rates.

Efforts are often made to minimize the size and impact of the HAZ in high-frequency welded finned tubes to ensure optimal performance and structural integrity. Control over welding parameters, such as power input, welding speed, and frequency, can help mitigate the effects of heat on the material. Additionally, post-weld heat treatments may be employed to alleviate residual stresses and refine the microstructure in the HAZ.

Understanding and managing the Heat Affected Zone is crucial in the fabrication of high-frequency welded finned tubes to ensure that the welded joints meet the required standards for strength, durability, and corrosion resistance. Proper welding techniques and quality control measures are essential to minimize the adverse effects of the HAZ and to produce finned tubes that perform reliably in their intended applications.