What are the Effects of Heat-Affected Zones in Finned Tubes?

2024-03-24Leave a message

What are the Effects of Heat-Affected Zones in Finned Tubes?

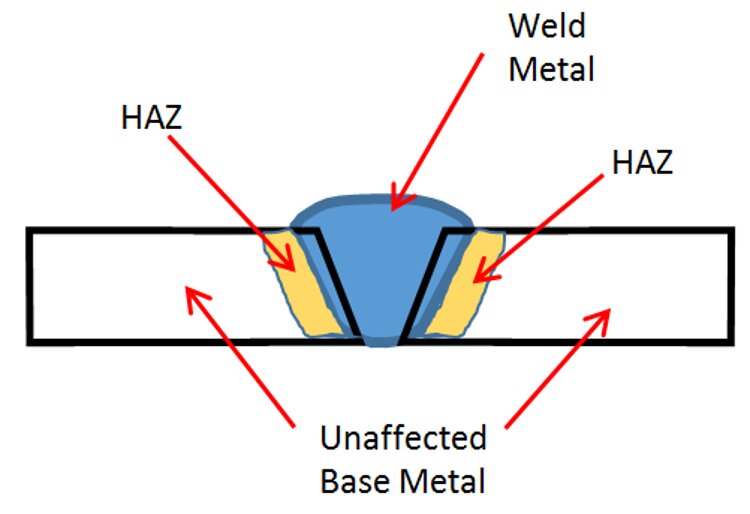

In finned tubes, the Heat-Affected Zone (HAZ) plays a crucial role in determining the structural integrity and performance of welded joints. The heating experienced within the HAZ induces changes in microstructure and properties, deviating from those of the base material. These alterations can have various effects, which may include:

1. Altered Mechanical Properties: The HAZ may exhibit higher or lower strength, reduced toughness, or increased susceptibility to cracking, depending on the material and the specifics of the welding process. Such variations can pose challenges in design and usage of components.

2. Corrosion Susceptibility: High temperatures in the HAZ, particularly in stainless steels, can lead to reduced corrosion resistance. Precipitation of chromium carbides around grain boundaries can lower the local chromium content, compromising the materials ability to form a passive film and leading to intergranular corrosion.

3. Hydrogen Embrittlement: In conventional steels, hydrogen embrittlement may occur as a result of atomic hydrogen dissolved in the weld metal being trapped and subsequently rejected into the HAZ during cooling. This can create internal pressures within the lattice, potentially causing cracking. Proper selection of welding parameters and preheating or postheating can help mitigate this effect.

4. Material Hardness Variations: The HAZ may exhibit hardness and strength differences compared to the parent material, which can present challenges in component design and usage, particularly in aluminum alloys where the HAZ may be softer and weaker.

How to Reduce the Heat Affected Zone?

To mitigate the adverse effects associated with the HAZ in finned tubes, several strategies can be employed:

1. Heat Treatment: Post-weld heat treatment can help alleviate HAZ-related issues by modifying the microstructure and properties of the affected region. The specific heat treatment process applied depends on the desired material properties and required changes.

2. Careful Cutting and Grinding: Precision cutting and grinding techniques can minimize the size and impact of the HAZ. However, care must be taken to avoid introducing additional heat during these processes.

3. Machining: Machining offers an effective way to remove the entire HAZ but may result in material loss and increased production time and cost.

4. Removal of Heat Tint: Heat tint resulting from oxidation can be removed using grinding or fine sandpaper, exposing the underlying layer and promoting self-passivation of chromium. However, this may weaken the part.

5. Optimized Welding and Cutting Processes: Selecting the appropriate welding or cutting process for the material can help minimize the size and severity of the HAZ, thereby reducing associated challenges.

By implementing these strategies, the presence and impact of the Heat Affected Zone in finned tubes can be effectively managed, ensuring the integrity and performance of welded joints in various applications.

Effects of Heat-Affected Zones (HAZ) in Welded Finned Tubes

In welded finned tubes, the Heat-Affected Zone (HAZ) analysis is vital for understanding the structural and performance implications of welding processes. The HAZ, resulting from the intense heat generated during welding, presents distinct characteristics and challenges:

1. Microstructural Changes: The HAZ experiences rapid heating and cooling cycles, leading to alterations in its microstructure compared to the base material. These changes can include grain growth, phase transformations, and the formation of precipitates, influencing mechanical properties such as strength, toughness, and ductility.

2. Mechanical Property Variations: Variations in mechanical properties across the HAZ can affect the overall integrity of welded joints. The zone adjacent to the weld bead may exhibit higher hardness and reduced ductility due to rapid cooling, while further away, the material may retain closer properties to the base metal.

3. Residual Stresses: Welding-induced thermal gradients can result in residual stresses within the HAZ, affecting dimensional stability and susceptibility to stress corrosion cracking. Residual stresses may concentrate at the boundaries between different regions of the HAZ, exacerbating the risk of cracking.

4. Corrosion Susceptibility: The altered microstructure and composition of the HAZ may render it more susceptible to corrosion compared to the base material. Localized depletion of alloying elements, such as chromium in stainless steels, can compromise the materials passive film formation and increase vulnerability to corrosion attacks.

5. Hydrogen Embrittlement: Hydrogen generated during welding processes can diffuse into the HAZ, leading to embrittlement and increased susceptibility to cracking, particularly in high-strength steels and other hydrogen-sensitive materials.

Analyzing the HAZ in welded finned tubes involves:

- Microstructural Examination: Utilizing microscopy techniques to investigate the grain structure, phase distribution, and presence of defects or precipitates within the HAZ.

- Mechanical Testing: Conducting tensile, hardness, and impact tests across the HAZ to assess variations in mechanical properties and identify potential weak zones.

- Residual Stress Measurement: Employing non-destructive techniques like X-ray diffraction or strain gauges to quantify residual stresses and their distribution within the welded joint.

- Corrosion Testing: Subjecting HAZ specimens to corrosion tests, such as salt spray or electrochemical methods, to evaluate their susceptibility to corrosion under relevant service conditions.

- Hydrogen Embrittlement Assessment: Performing hydrogen-induced cracking tests, such as slow strain rate or hydrogen permeation tests, to assess the materials susceptibility to hydrogen embrittlement.

By comprehensively analyzing the HAZ in welded finned tubes, manufacturers and engineers can optimize welding parameters, select appropriate materials, and implement post-weld treatments to mitigate potential issues and ensure the integrity and reliability of welded joints in various applications.