Lord Fin Tube--Introduce Heat Pipe

What is a heat pipe?

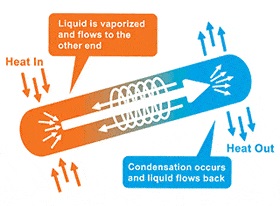

A heat pipe is a tube with high-efficiency heat transfer performance. It is an evaporation-condensation heat exchange device. The heat transfer is realized by the state change of the medium in the tube. The heat transfer is realized by the state change of the working medium in the tube. A heat pipe is an exceptionally efficient conductor of heat. It typically consists of a sealed vessel with inner walls lined with a wick structure. First, the vessel is vacuumed and then filled with a working fluid before being hermetically sealed. When heat is applied to one end of the heat pipe, the working fluid evaporates from liquid to vapor, undergoing a phase change. This vapor moves through the hollow core of the heat pipe at nearly sonic speeds to the opposite end, where heat is extracted by a heat sink or another method. There, the vapor condenses back into liquid, releasing heat in the process. The liquid then returns to the original end of the heat pipe through the wick via capillary action. The energy needed for the liquid to transform into vapor is known as the latent heat of evaporation.

The principle of heat pipe?

The heat pipe uses evaporative cooling to make the temperature difference between the two ends of the heat pipe very large, so that the heat can be conducted quickly. Common heat pipes are composed of tube shells, liquid-absorbing cores and end caps. The production method is to pump the inside of the heat pipe into a negative pressure state, and then fill it with a suitable liquid, which has a very low boiling point and is easy to volatilize. The tube wall has a liquid-absorbing core, which is made of capillary porous material.

One end of the heat pipe is the evaporation end, and the other end is the condensation end. When one section of the heat pipe is heated, the liquid in the capillary evaporates rapidly, and the vapor flows to the other end under a slight pressure difference, and releases heat, and recondenses into a liquid. The liquid flows back to the evaporating section along the porous material by capillary force, and the cycle is endless. Heat is transferred from one end of the heat pipe to the other end. This cycle is carried out quickly, and the heat can be continuously conducted.

Technical characteristics of heat pipe

1. High speed heat conduction effect

1. High speed heat conduction effect

2. Light weight and simple structure

3. Even temperature distribution, can be used for uniform temperature or isothermal action.

4. Large heat transfer capacity. Heat transfer distance is long.

5. There are no active components, and it does not consume power itself.

6. There is no restriction on the direction of heat transfer, and the evaporation end and condensation end can be interchanged.

7. Easy to process to change the direction of heat transfer.

8. Durable, long life, reliable, easy to store and keep.

Heat pipe manufacturing process and testing:

1. Selection of working fluid: non-flammability, operating temperature, heat transfer, allowable thermal resistance, and economy.

2. Selection of container materials: thermal conductivity, vacuum maintenance, pressure resistance, fluid compatibility (corrosion, chemical reaction).

3. Container and injection processing: length, deburring, cleaning, sealing, preservation. Leak testing is: helium leak detection, high pressure bubble inspection (to prevent pinholes, cracks and oxidation in containers).

4. Vacuum baking: dehydration and deoxidation on the capillary surface of the heat pipe assembly under high temperature and vacuum environment.

5. Vacuum treatment of working fluid: heating out (liquid state), gaseous liquefaction (gas state), vacuum mercury filling method. Injection sealing: tungsten electrode pure gas welding (this is the only leak-proof sealing method for heat pipes).

6. Sampling test: Oxidation/corrosion durability test, maximum heat transfer performance test, maximum bending/flat post leakage test, maximum bending/flat post performance test, life test.