Lord Fin Tube-Heat recovery steam generator

What is Heat Recovery Steam Generator (HRSG)

A heat recovery steam generator (HRSG) is an energy recovery device that captures heat from a hot gas stream. This captured heat is used to produce steam, which can be employed in cogeneration processes or to drive a turbine in combined cycle operations.

Components of HRSGs

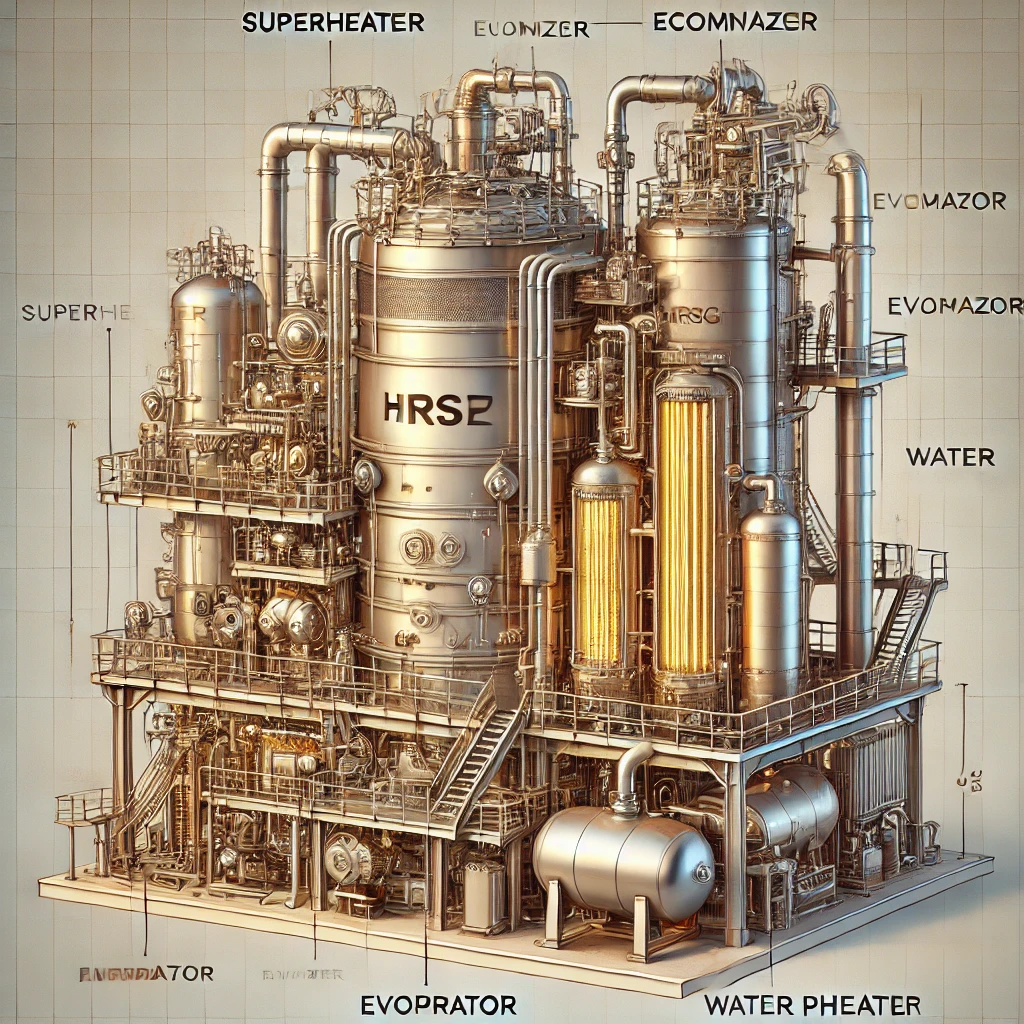

HRSGs consist of four major components: the superheater, economizer, evaporator, and water preheater. These components are arranged to meet the operational requirements of the unit. Refer to the attached illustration of a typical HRSG general arrangement for more details.

A Heat Recovery Steam Generator (HRSG) comprises four major components that work together to capture and utilize waste heat from a hot gas stream to produce steam. Here are the components:

1. Superheater:

Function: The superheater increases the temperature of steam beyond its saturation point without raising its pressure. This superheated steam is then used in turbines for electricity generation or industrial processes.

Operation: It is located downstream in the gas path and receives saturated steam from the steam drum.

2. Economizer:

Function: The economizer preheats the feedwater before it enters the evaporator section. This increases the efficiency of the HRSG by reducing the amount of fuel needed to produce steam.

Operation: It uses the residual heat from the exhaust gases to heat the water, which enters the steam drum at a higher temperature.

3. Evaporator:

Function: The evaporator is where the actual steam generation occurs. Water is converted into steam by absorbing heat from the hot gases.

Operation: It typically contains a series of tubes arranged to maximize heat transfer from the hot gases to the water inside the tubes. The steam produced is collected in the steam drum.

4. Water Preheater:

Function: The water preheater increases the temperature of the feedwater entering the economizer. This further enhances the overall efficiency of the HRSG.

Operation: It uses lower-temperature exhaust gases to heat the incoming feedwater before it reaches the economizer.

These components are assembled in various configurations to meet specific operational requirements and optimize heat recovery efficiency. The arrangement and design of these components can vary based on the type of HRSG, whether it is a single-pressure or multi-pressure system, and the direction of exhaust gas flow (vertical or horizontal).

Types of HRSGs

HRSGs can be classified in several ways, such as by the direction of exhaust gas flow or the number of pressure levels:

1. Exhaust Gas Flow Direction:

Vertical Type: Exhaust gas flows vertically over horizontal tubes.

Horizontal Type: Exhaust gas flows horizontally over vertical tubes.

2. Pressure Levels:

Single Pressure HRSGs: These have one steam drum and generate steam at a single pressure.

Multi-Pressure HRSGs: These have two or three steam drums, corresponding to double or triple pressure systems. Triple pressure HRSGs have three sections: low pressure (LP), intermediate pressure (IP), and high pressure (HP). Each section includes a steam drum and an evaporator section where water is converted to steam, which then passes through superheaters to increase the temperature beyond saturation.

Heat Recovery Steam Generator (HRSG) Applications

HRSGs are widely used in energy projects:

In the energy-rich Gulf region, steam from HRSGs is used in desalination plants.

Universities can use turbines to generate reliable electricity for campus use, and HRSGs can recover heat from the turbines to produce steam or hot water for district heating or cooling.

Large ocean vessels, such as the Emma Maersk, utilize heat recovery systems.

Heat Recovery Steam Generator (HRSG) Manufacturers

Alstom

Ansaldo Caldaie S.p.a.

BHI Co.

Express Integrated Technologies (EIT)

Vogt Power/Babcock Power

IHI Corporation

CMI Energy

Victory Energy

Nooter/Eriksen

NEM

Doosan Heavy Industries & Construction

BHEL

3DCAD (I) PVT LTD

Thermax Ltd

Innovative Steam Technologies

Larsen & Toubro Ltd

Hamon Deltak, Inc

Greshams Ltd

Rentech Boiler Inc.

AZARAB Industry Co.

DESCON Engineering Limited

Retubeco, Inc.

GREENS POWER EQUIPMENT INDIA PVT.LTD.

MAPNA Boiler