Lord Fin Tube--High fin tubes

What are high fin tubes?

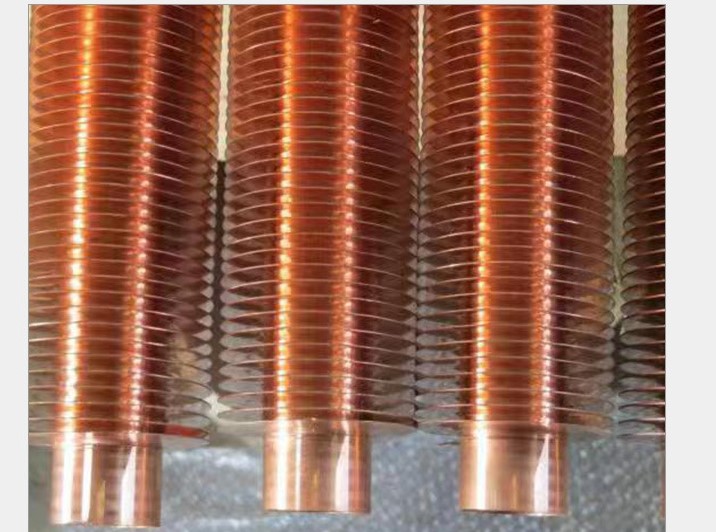

High-fin tubes, also known as integral finned tubes or extruded finned tubes, are specialized heat transfer components designed to enhance heat exchange efficiency. They feature a series of fins that are tightly integrated or extruded onto the outer surface of a base tube.

The primary purpose of high-fin tubes is to increase the surface area available for heat transfer. By incorporating fins onto the tube, the effective surface area is significantly expanded, allowing for improved heat transfer between the fluid inside the tube and the surrounding medium.

The fins on high-fin tubes can vary in size, shape, and configuration, depending on the specific application requirements. They are typically taller and more closely spaced compared to regular fins, maximizing the surface area and promoting efficient heat exchange.

The manufacturing process of high-fin tubes involves extruding or integrally bonding the fins onto the base tube. This ensures a strong mechanical bond and enables efficient heat transfer by eliminating any air gaps or thermal barriers between the fins and the tube.

High-fin tubes are commonly made from materials such as copper, aluminum, or stainless steel, depending on the specific application and its requirements for corrosion resistance, thermal conductivity, and mechanical strength.

These tubes find wide application in heat exchangers, air coolers, condensers, and other heat transfer systems. They are particularly useful in industries such as HVAC, refrigeration, power generation, and process industries where efficient heat transfer is crucial.

High fin tube common material:

High fin tubes are generally made of copper or copper alloy tubes. Copper has excellent thermal conductivity, so it is widely used in applications such as heat exchangers that require high-efficiency heat transfer. Copper alloys are also commonly chosen because they may have better mechanical properties or corrosion resistance while maintaining the high thermal conductivity of copper. The fin portion of high fin tubes typically uses aluminum or aluminum alloy because aluminum has good thermal conductivity and is relatively lightweight, which helps to enhance heat transfer efficiency.

The advantages of high-fin tubes:

1. Enhanced Heat Transfer: The increased surface area provided by the fins improves heat exchange efficiency, allowing for more effective cooling or heating.

2. Compact Design: High-fin tubes offer a higher surface area-to-volume ratio, enabling the construction of more compact and efficient heat exchangers.

3. Improved Performance: The extended surface area of the fins allows for higher heat transfer rates and better overall system performance.

4. Reduced Fouling: The closely spaced fins on high-fin tubes help minimize fouling by preventing the accumulation of debris or deposits on the tube surface.

5. Customization: The design and dimensions of the fins can be tailored to meet specific heat transfer requirements, allowing for optimal performance in various applications.

High-fin tubes are heat transfer components that feature closely spaced fins extruded or integrally bonded onto the base tube. They offer increased surface area, improved heat transfer efficiency, and find extensive use in various industries requiring efficient heat exchange.