How to check the welding process of laser welding fin tube?

Laser Welding Fin Tube Inspection

Laser welding fin tube inspection is a critical quality control process that ensures the integrity and performance of heat exchanger components by systematically evaluating the weld quality at various stages, beginning with pre-welding material and equipment checks, followed by real-time monitoring of laser parameters (power, speed, gas flow) during welding, and concluding with comprehensive post-weld evaluations including non-destructive testing (ultrasonic, X-ray, dye penetrant), mechanical tests (tensile, hardness, bend), and geometric measurements to verify dimensional accuracy, all supported by detailed documentation and corrective action protocols to maintain consistent weld quality and compliance with industry standards.

1. Pre-Welding Checks

Material Inspection

- Verify cleanliness (no oil, rust, or contaminants)

- Check fin/tube dimensions and alignment

Equipment Setup

- Calibrate laser power, speed, focus, and shielding gas flow

- Ensure fixtures securely hold tubes/fins without misalignment

2. In-Process Monitoring

Parameter Tracking

- Monitor laser power, welding speed, and gas flow in real-time

- Use sensors/cameras to detect irregularities

Visual Checks

- Look for discoloration, burn marks, or inconsistent weld penetration

3. Post-Welding Inspection

Non-Destructive Testing (NDT)

| Method | Purpose |

|---|---|

| Ultrasonic Testing (UT) | Detects internal voids/cracks |

| X-ray Inspection | Reveals subsurface defects (porosity, inclusions) |

| Dye Penetrant (DPI) | Identifies surface cracks |

| Magnetic Particle (MPI) | For ferromagnetic materials (surface/near-surface flaws) |

Mechanical Testing

| Test | Purpose |

|---|---|

| Tensile Test | Ensures weld strength meets specifications |

| Hardness Test | Checks uniformity across weld zones |

| Bend Test | Assesses ductility and crack resistance |

Acoustic/Geometric Checks

- Delay Time Measurement: Calibrate acoustic monitoring systems

- Probe Synchronization: Ensure uniform movement of probes

- Measurement Intervals:

- Standard: 40 cm between points

- Defect detected? Reduce to 20 cm

4. Documentation & Compliance

- Record all parameters, NDT results, and corrective actions

- Perform random sampling:

- ≤5% delay time deviation

- ≤10% amplitude deviation

- Maintain equipment calibration logs

5. Corrective Actions

- Defect Resolution: Adjust parameters or rework welds

- Root Cause Analysis: Address contamination or misalignment

6. Continuous Improvement

- Review weld data trends to optimize processes

- Train operators on defect recognition

Laser welding fin tube inspection is a critical quality control process that ensures the integrity and performance of heat exchanger components by systematically evaluating the weld quality at various stages, beginning with pre-welding material and equipment checks, followed by real-time monitoring of laser parameters (power, speed, gas flow) during welding, and concluding with comprehensive post-weld evaluations including non-destructive testing (ultrasonic, X-ray, dye penetrant), mechanical tests (tensile, hardness, bend), and geometric measurements to verify dimensional accuracy, all supported by detailed documentation and corrective action protocols to maintain consistent weld quality and compliance with industry standards.

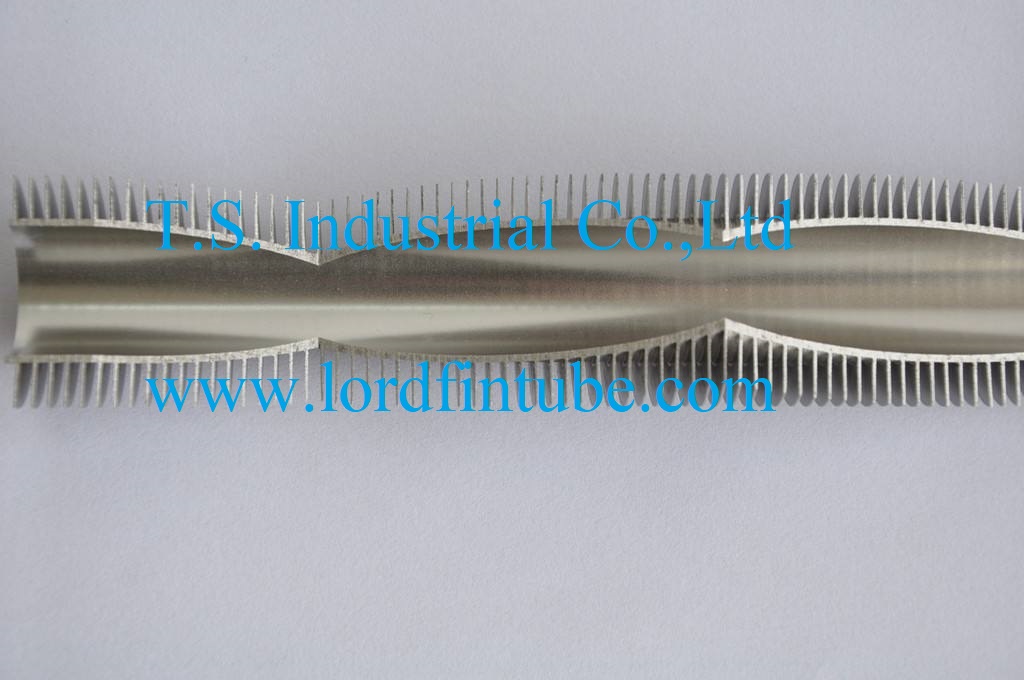

Laser welding fin tubes