How to make tube sheets?

How to make tube sheets?

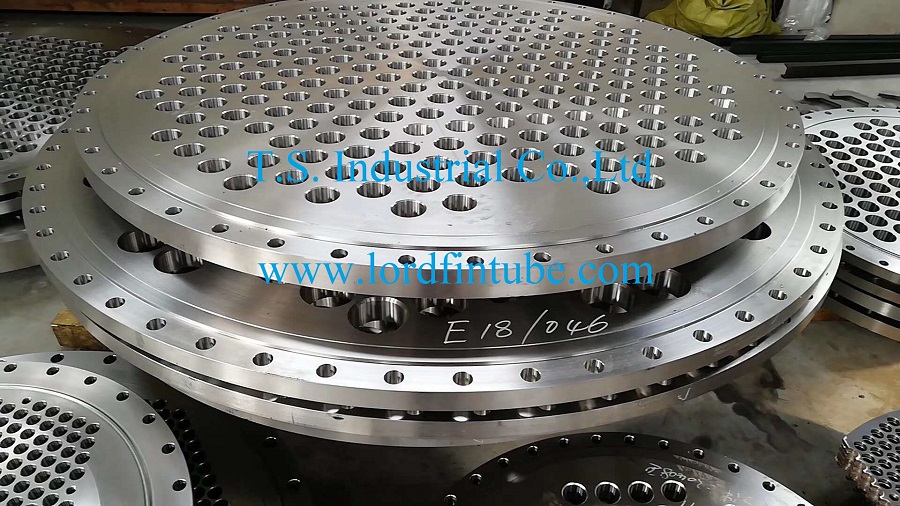

Tube sheets are critical components in heat exchangers, boilers, and other similar equipment where tubes need to be connected to a larger structure. The tube sheet provides support and facilitates the efficient transfer of heat between the tubes and the surrounding fluid.

The process of making tube sheets involves several steps:

1. Tube Sheet Material Selection:

- Tube sheets are typically made from metals like carbon steel, stainless steel, or other alloys depending on the application and the fluids involved.

2. Tube Sheet Cutting and Shaping:

- The tube sheet is usually a flat, circular or rectangular plate. It can be cut and shaped from a larger metal sheet using various methods such as plasma cutting, laser cutting, or machining.

3. Tube Sheet Drilling Holes:

- One of the critical steps in making a tube sheet is drilling holes for the tubes. These holes need to be accurately positioned and dimensioned to ensure a proper fit for the tubes. The process can be done using drilling machines, milling machines, or other machining tools.

4. Tube Hole Expansion:

- After the holes are drilled, tube holes may undergo a process called tube hole expansion. This involves using tools to slightly enlarge and smooth the openings to facilitate the insertion of the tubes.

5. Tube Installation:

- Once the tube sheet is prepared, tubes are inserted into the drilled holes. This can involve welding, expanding, or mechanically attaching the tubes to the tube sheet, depending on the design and requirements of the heat exchanger or boiler.

6. Tube Sheet Welding:

- Welding is often used to secure the tubes to the tube sheet. This creates a strong and durable connection between the tubes and the sheet. Proper welding techniques are crucial to ensure the integrity of the joint.

7. Tube Sheet Quality Control:

- Quality control measures are implemented throughout the process. This includes checking the dimensions, alignment, and material integrity to ensure that the tube sheet meets the required specifications and standards.

8. Tube Sheet Surface Treatment:

- Depending on the application, the tube sheet may undergo surface treatments such as painting or coating to protect it from corrosion or other environmental factors.

The specific details of the manufacturing process can vary based on the type of equipment, the materials used, and the engineering specifications. The goal is to create a tube sheet that is strong, precise, and capable of withstanding the conditions it will encounter in its intended application.