Jumper Pipe with Elbows for Industrial Boiler Systems

Jumper pipes with elbows are critical components in industrial boiler systems, specifically engineered for high-temperature and high-pressure environments. These specialized piping assemblies serve as vital connectors in boiler piping networks, ensuring efficient fluid transfer while mitigating stress caused by thermal expansion, contraction, and pressure fluctuations.

In applications ranging from high-pressure steam boilers to heat recovery systems and industrial thermal processing equipment, jumper pipes with elbows optimize fluid dynamics, enhance system efficiency, and prevent turbulence and pressure losses at directional changes. Their exceptional temperature resistance and corrosion-resistant properties make them indispensable across power generation, petrochemical, chemical processing, and shipbuilding industries, ensuring long-term operational stability.

What is a Jumper Pipe with Elbows?

A jumper pipe with elbows is a precision-engineered piping assembly comprising a central pipe segment integrated with two elbows and straight pipe ends. This configuration is specifically designed for industrial boilers and high-pressure fluid transfer systems to redirect fluid flow or navigate around obstructions, optimizing pipeline architecture.

These components are manufactured from high-performance materials including carbon steel, stainless steel, or nickel alloys to ensure durability in extreme temperature, pressure, and corrosive conditions. Their application spans boiler systems, steam networks, heat exchange equipment, and pressure vessel piping, guaranteeing both operational efficiency and system integrity.

Benefits of Jumper Pipes with Elbows

- Superior Stress Management: Effectively disperses thermal and mechanical stresses

- Enhanced Flow Efficiency: Optimizes fluid dynamics with minimal pressure drop

- Space Optimization: Accommodates complex spatial constraints in industrial settings

- Extended System Lifespan: Reduces wear and maintenance requirements

- Custom Configuration: Adaptable to specific operational requirements

Jumper Pipe with Elbows Functions in Boiler Systems

1. Connecting Boiler Pipes and Optimizing Fluid Dynamics

In boiler pressure systems, efficient fluid transfer demands flexible piping configurations. Jumper pipes with elbows facilitate directional changes in pipelines, enabling smooth transit of steam, water, and other high-temperature media while preventing turbulence and pressure degradation associated with abrupt directional changes.

2. Stress Reduction and System Longevity

High-temperature and high-pressure conditions can induce pipeline deformation through thermal expansion or mechanical stress, potentially compromising system integrity. Jumper pipes with elbows function as transitional elements, effectively distributing stress concentrations and minimizing potential failure points, thereby reducing the risk of pipe fractures or leakage.

3. Adaptation to Complex Spatial Constraints

Boiler installations frequently encounter space limitations where conventional straight piping proves inadequate. Jumper pipes with elbows enable flexible routing within confined areas, navigating obstacles and accommodating equipment spacing requirements, resulting in more compact and efficient system designs.

4. Boiler System Efficiency Enhancement

Advanced elbow geometries minimize flow resistance, reducing energy consumption and improving overall thermal efficiency. Properly designed elbows also discourage sediment accumulation, decreasing maintenance frequency and ensuring consistent long-term performance.

Technical Specifications and Material Selection

Jumper pipes with elbows must comply with rigorous technical standards to ensure reliability in demanding high-temperature and high-pressure applications. Critical technical parameters include:

Material Grades (ASTM/ASME Compliance)

Material selection prioritizes exceptional heat resistance, corrosion resistance, and mechanical strength, conforming to ASTM and ASME standards. Common material options include:

| Material | Standards & Grades | Key Properties | Typical Applications |

|---|---|---|---|

| Carbon Steel | ASTM A106 Gr.B ASTM A53 Gr.B |

Cost-effective durability for medium temperature and high-pressure applications | Standard boiler piping, steam lines |

| Alloy Steel | ASTM A335 P11/P22/P91 |

Superior high-temperature oxidation resistance and pressure capability | High-temperature/high-pressure boilers, petrochemical equipment |

| Stainless Steel | ASTM A312 TP304/TP316 |

Exceptional corrosion resistance for high-temperature or corrosive environments | Chemical processing, food industry, desalination plants |

| Nickel Alloy | ASTM B366 Inconel 600/625/Hastelloy C22 |

Outstanding corrosion and extreme temperature resistance | Ultra-high temperature and highly corrosive environments |

Bending Radius Specifications

The bending radius significantly influences flow characteristics and system performance:

- R = 1D: Short-radius elbow for space-constrained applications (higher flow resistance)

- R = 1.5D: Long-radius elbow offering balanced flow stability and spatial efficiency

- R = 3D+: Extended radius for high-flow applications with minimal resistance

Wall Thickness Tolerance

Wall thickness must conform to international standards, typically maintained within ±10% tolerance to ensure mechanical integrity and pressure containment. Standard specifications include ANSI B16.9 (industrial fittings) and EN 10253 (European standards), with common thickness schedules including SCH 10, 40, 80, 160, and XXS for extra-heavy applications.

Ovality and Wall Thinning Control

Manufacturing processes strictly control dimensional parameters to ensure optimal fluid flow and minimize stress concentrations. Ovality is typically maintained within ≤1% of nominal diameter, while wall thinning during bending processes is controlled to ≤12.5% to preserve pressure integrity.

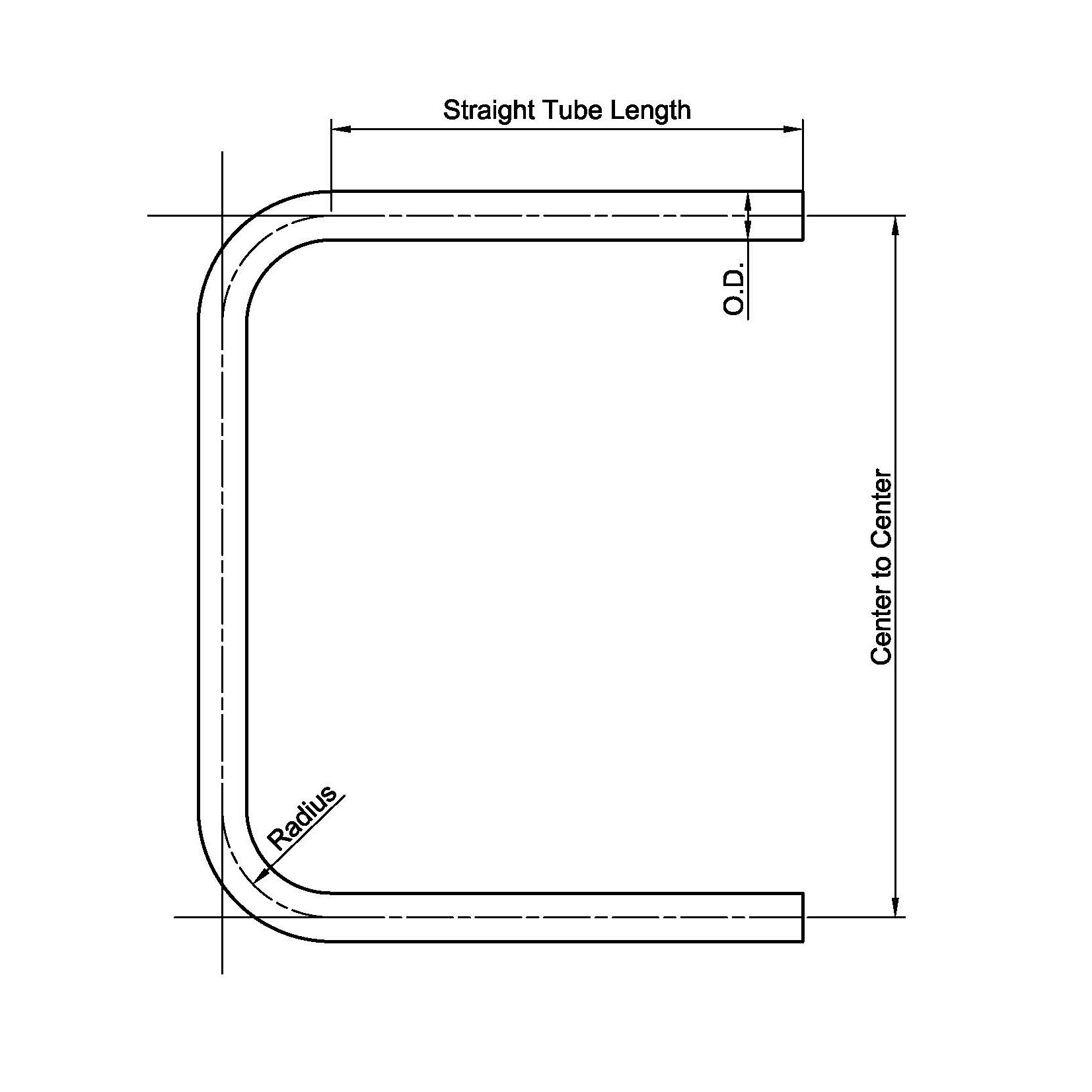

Detailed dimensional specifications of jumper pipes with elbows

Jumper Pipe with Elbows Manufacturing Processes

Cold Bending Process

Cold forming at ambient temperature using specialized benders or dies, ideal for small-diameter pipes of carbon steel, stainless steel, and select alloys.

Advantages: High dimensional accuracy, superior surface finish, preservation of material properties

Applications: Precision instrumentation, food-grade systems, automotive exhaust, low-pressure steam lines

Hot Bending Process

Forming at elevated temperatures (900–1000°C material-dependent) using induction or flame bending techniques.

Advantages: Suitable for large-diameter thick-walled pipes, minimal springback, ideal for high-strength alloys

Applications: High-temperature/pressure boiler systems, oil/gas pipelines, power generation facilities

Hot Bending + Press Forming

Combined thermal and mechanical forming for uniform wall distribution and reduced stress concentration.

Advantages: Optimized wall thickness, enhanced pressure resistance, superior dimensional stability

Applications: Ultra-high-pressure systems, nuclear power components, critical petrochemical applications

Jumper Pipe with Elbows Characteristics

- Exceptional corrosion and temperature resistance

- Enhanced system efficiency and operational stability

- Customizable configurations for specific application requirements

- Superior cost-performance ratio

- Reduced maintenance frequency and extended service life

Industrial Applications

Power Generation

Ensuring reliable high-pressure steam transfer in power plant boilers with optimized flow characteristics and stress management.

Petrochemical Industry

Corrosion-resistant configurations for high-temperature chemical fluid transfer in refining and processing facilities.

Heat Recovery Systems

Connecting heat exchangers and waste heat boilers with efficient directional change capabilities.

Industrial Processing

Interconnecting pressure vessels and thermal processing equipment in various manufacturing applications.

How to Choose Jumper Pipe with Elbows

Choosing the appropriate jumper pipe with elbows is crucial for ensuring operational reliability in industrial boiler systems, petrochemical equipment, and high-pressure fluid networks. Proper selection optimizes fluid dynamics, reduces pressure losses, extends system longevity, and minimizes maintenance costs.

Selection Criteria:

Size and Dimensional Parameters

Select pipe diameter and wall thickness based on system flow requirements and pressure specifications, considering both current operational needs and potential future capacity increases.

Material Compatibility

Choose materials based on corrosion resistance requirements, temperature exposure, and pressure conditions specific to your application environment.

Bending Angle Configuration

Elbow geometry determines fluid flow direction and should align with pipeline layout requirements:

- 45° Elbows: Minor directional adjustments with minimal pressure loss

- 90° Elbows: Standard directional changes available in long radius (LR) or short radius (SR)

- 180° Elbows: U-bend configurations for heat exchange or reflux applications

- Custom Angles: Specialized configurations (30°, 60°, 120°) for complex routing requirements

Connection Methodology

Jumper pipes with elbows support various connection types to accommodate different installation and maintenance requirements:

- Butt-Weld (BW): Maximum strength for high-pressure/high-temperature systems

- Socket-Weld (SW): Ideal for small-diameter high-pressure applications

- Threaded (NPT/BSP): Suitable for low-pressure systems requiring disassembly capability

- Flanged: Facilitates maintenance access and system modifications

Technical Note: For high-temperature and high-pressure applications, butt-weld connections are recommended to ensure sealing integrity and structural strength.

Quality Assurance and Certification

Our manufacturing processes adhere to international quality management systems with comprehensive testing protocols to ensure every product meets the highest industry standards. All components are manufactured from premium materials conforming to ASTM, ASME, EN, DIN, and GB specifications.

Each jumper pipe with elbows undergoes rigorous dimensional inspection, wall thickness verification, and ovality assessment, supported by complete material certification documentation and traceability.