KL-type integral finned tube|rolled finned tube

2024-03-10Leave a message

What is KL-type integral finned tube?

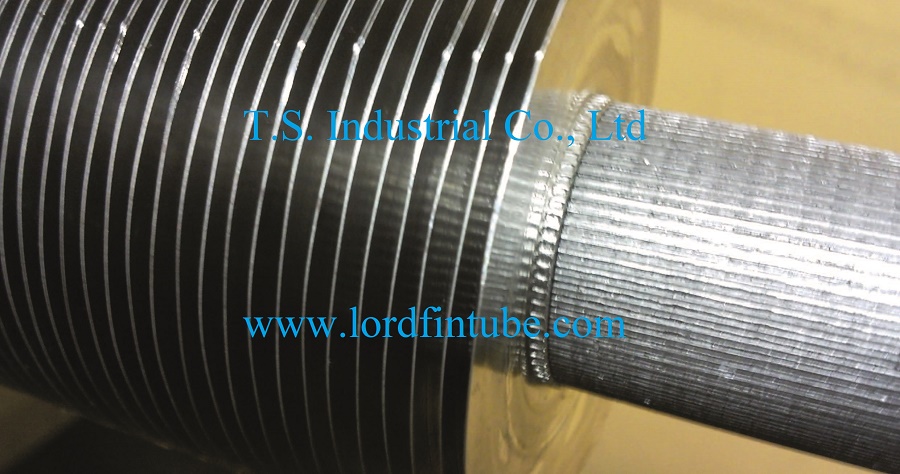

KL-type integral fin tube, also known as "rolled finned tube," is a specialized piping component designed for heat transfer, featuring a pattern of rolled grooves and spirally arranged fins. It is commonly used for heating or cooling fluids. Below is a more detailed description of KL-type integral finned tubes:

KL-Type Integral Fin Tube Manufacturing Process:

- In the production of KL-type integral finned tubes, the pipe surface undergoes a rolling process first. This step typically involves rolling a pattern onto the base pipe or using a finning machine with an attached blade to create grooves on the base pipe surface. These grooves enhance surface roughness, improving adhesion with the fins.

- Subsequently, fins are wound onto the grooved surface. Fins are usually thin, elongated metal strips that are mechanically wound or fixed in a spiral manner along the grooved surface of the pipe.

KL-Type Integral Fin Tube Scope of Application:

- Operating Temperature: KL-type integral finned tubes are suitable for high-temperature conditions, typically up to 250°C.

- Operating Pressure: They can operate under relatively high pressures, generally not exceeding 3.2MPa.

KL-Type Integral Fin Tube Advantages:

1. High Heat Transfer Efficiency: The design of KL-type integral finned tubes significantly increases the effective heat transfer surface area of the pipe, thereby enhancing heat transfer efficiency. The spiral arrangement of fins ensures thorough contact between the fluid and the pipe surface, facilitating efficient heat transfer.

2. Tight Fit: The large contact area between fins and the pipe surface ensures a tight fit, minimizing thermal resistance and enhancing heat transfer effectiveness.

3. Structural Stability: The manufacturing process involving rolling and spiral winding ensures a robust connection between the fins and the base pipe, resulting in structural stability. This enables long-term stable operation with minimal risk of detachment or damage.

4. Corrosion Resistance: KL-type integral finned tubes are typically made from corrosion-resistant materials, exhibiting good resistance to atmospheric corrosion and making them suitable for harsh operating environments.

KL-Type Integral Fin Tube Applications:

KL-type integral finned tubes find widespread use in various industrial applications requiring efficient heat transfer, including:

- Air conditioning systems for air cooling or heating.

- Cooling towers for fluid cooling in industrial processes.

- Automotive radiators for engine cooling.

- Heat exchange equipment in chemical processes.

In summary, KL-type integral finned tubes play a crucial role in industrial production due to their high heat transfer efficiency, structural stability, and corrosion resistance. They are indispensable components in many heat transfer systems.