Lord Fin Tube-A213 TP304 Laser welding finned tube

ASTM A213 TP304 Laser-Welded Finned Tubes

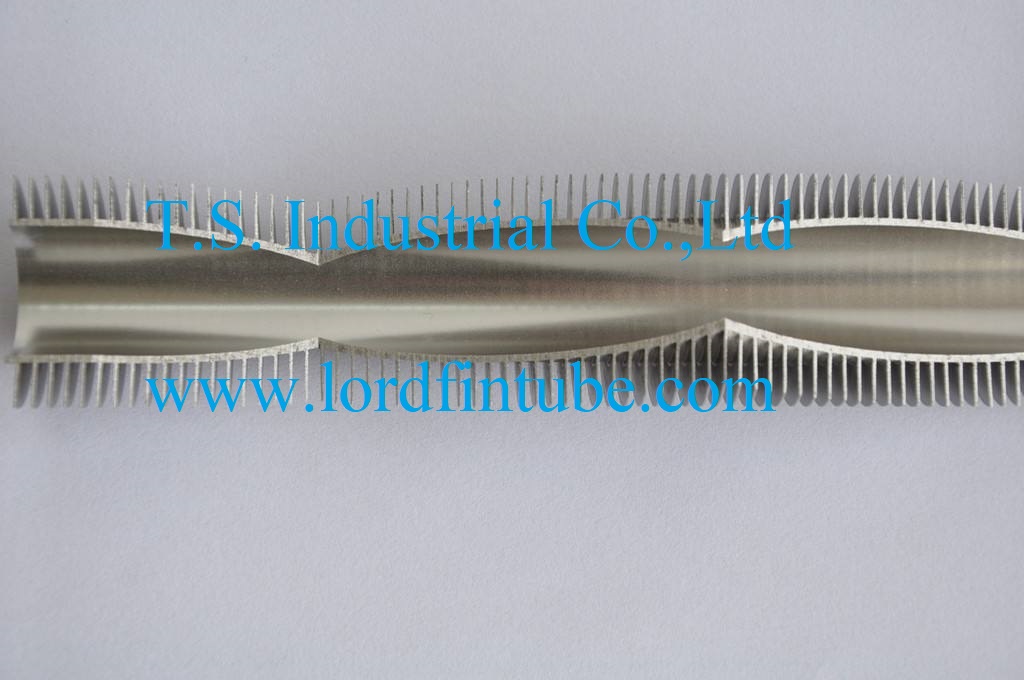

ASTM A213 TP304 laser-welded finned tubes represent the pinnacle of heat transfer technology, combining premium austenitic stainless steel with precision laser welding to deliver exceptional performance in demanding thermal applications.

ASTM A213 TP304 Material Properties

ASTM A213 TP304 is a standard specification for seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. The TP304 grade specifically refers to a versatile austenitic chromium-nickel stainless steel with excellent corrosion resistance and formability.

Laser Welding Technology in Finned Tube Manufacturing

Laser welding technology revolutionizes finned tube production by creating a metallurgical bond between the base tube and fins through precise, high-energy laser beams. This process offers significant advantages over traditional welding methods:

Minimal Heat-Affected Zone

Laser welding creates an extremely narrow heat-affected zone (HAZ), preserving material properties and reducing thermal distortion.

Superior Bond Strength

The laser creates a deep, narrow weld with excellent penetration, resulting in joint strength often exceeding the base materials.

Precision and Consistency

Computer-controlled laser systems ensure consistent weld quality along the entire tube length, eliminating human error.

Standard Specifications and Dimensions

ASTM A213 TP304 Laser-Welded Finned Tubes - Typical Sizes

| Parameter | Standard Value | Available Range |

|---|---|---|

| Base Tube Outer Diameter | 25.4 mm | 15 mm - 60 mm |

| Base Tube Thickness | 1.0 mm | 0.8 mm - 2.0 mm |

| Fin Height | 9.53 mm | 6 mm - 16 mm |

| Fin Thickness | 0.5 mm | 0.3 mm - 1.0 mm |

| Fin Pitch | 2.1 mm | 1.8 mm - 4.0 mm |

| Tube Length | 9.144 meters | Up to 12 meters |

| Base Material | ASTM A213 TP304 | |

| Fin Material | Stainless Steel 304/316, Carbon Steel | |

Performance Advantages of Laser-Welded Finned Tubes

Industrial Applications

ASTM A213 TP304 laser-welded finned tubes are essential components across multiple industries where efficient heat transfer is critical:

Comparison with Other Fin Tube Types

| Fin Type | Thermal Efficiency | Corrosion Resistance | Pressure Withstanding | Cost Effectiveness |

|---|---|---|---|---|

| Laser Welded | Excellent | Excellent | High | Medium-High |

| High Frequency Welded | Good | Good | Medium | Medium |

| Extruded Fins | Good | Excellent | High | High |

| Embedded Fins | Fair | Fair | Low | Low |

Quality Assurance and Testing

All ASTM A213 TP304 laser-welded finned tubes undergo rigorous quality control procedures to ensure compliance with international standards:

Visual Inspection

100% visual examination for surface defects, weld consistency, and dimensional accuracy.

Hydrostatic Testing

Pressure testing to verify tube integrity and leak-proof performance.

Material Certification

Third-party verification of material composition and mechanical properties.

Installation and Maintenance

Proper installation is crucial for optimal performance of laser-welded finned tubes:

Technical Support and Custom Solutions

Our engineering team provides comprehensive technical support for ASTM A213 TP304 laser-welded finned tube applications, including custom designs for specific operational requirements, thermal performance analysis, and material selection guidance for unique service conditions.

ASTM A213 TP304 laser-welded finned tubes deliver unmatched performance in heat transfer applications, combining the corrosion resistance of 304 stainless steel with the precision of laser welding technology for superior efficiency and longevity.