Products Description

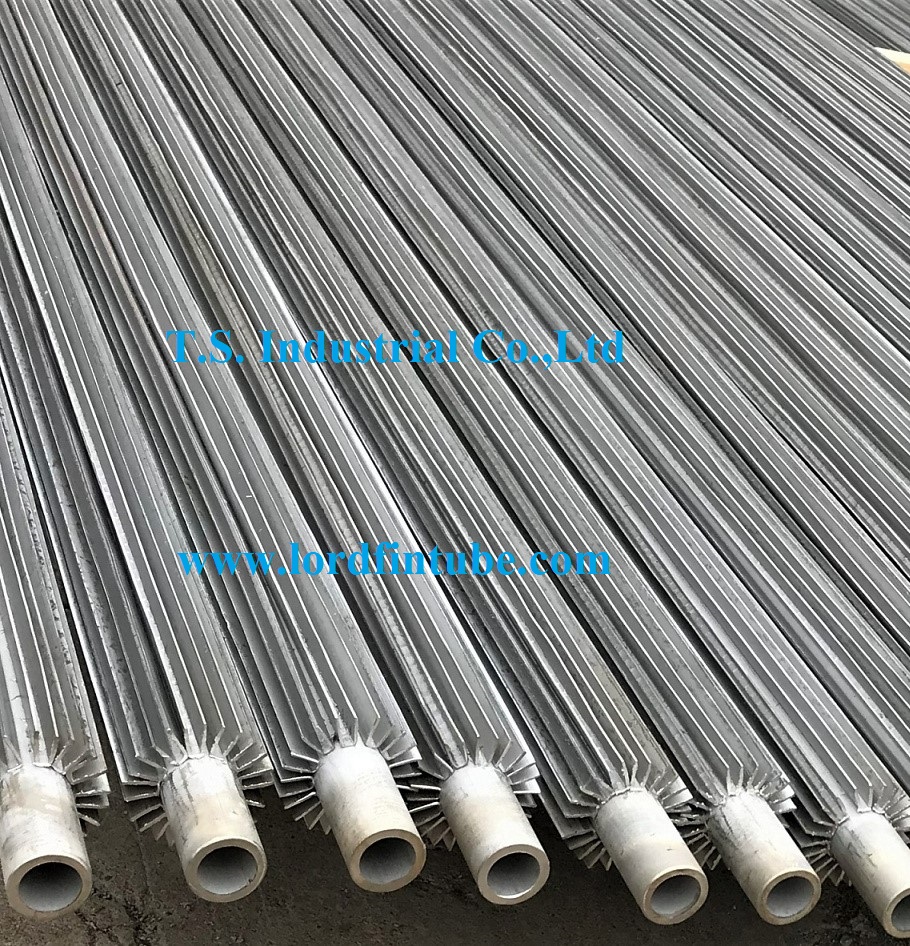

What is the longitudinal finned tubes?

Longitudinal Finned Tubes are produced by resistance welding the fins on the base tube in the longitudinal direction along the length of the tube. Welded Longitudinal Finned Tubes are created through resistance welding of fins along the length of the tube. Initially, the fin strip is shaped into a U-channel, with each leg of the U serving as a fin. The channels are then cut to the desired length and positioned longitudinally along the tube before being resistance welded in place. These channels are welded in pairs, positioned diametrically opposite one another, meaning that the specified number of fins must always be a multiple of four.

How the longitudinal finned tubes manufacturing process?

Firstly form the steel fin strip into a U-shaped channel, then each U channel form as a fin.

Then channels are cut to the appropriate length and then oriented along the length of the tube and resistance welded on tube.

The channels are welded in pairs, diametrically opposed, therefore the number of fins specified must always be a multiple of four.

The longitudinal I/L or U shape fins are welded onto the core plain tubes by resistance welding or welding with filler metal (Spot welded).

Longitudinal finned tubes supply range:

1. U bends tubes with longitudinal fins and fin tube coils are available for requesting.

2. Longitudinal fins types: one-piece shape, standard U bent shape, cut & twist, perforated type etc…

3. The fin channels are welded to the tubes in opposite pairs. Fin height, number of fins and fin thickness can be specified.

4. Fins can be applied to either OD tube or NB pipe.

Longitudinal finned tube applications:

The longitudinal finned tubes are widely used in following fields.

1. Chemical- ,petrochemical-,oil-, and power industry

2. Heat exchanges

3. Fired heaters

4. Gas coolers and heaters

5. Tank heaters.

Longitudinal Finned Tube material specifications:

Materials of tubes: Carbon Steel (A106/A179/A192/A210) Stainless Steel (ASTM A213 TP304/TP304L ,TP316/TP316L), Alloy Steel (ASTM A213 T11/T22) not limited

Fins Materials: Carbon Steel, Stainless Steel(TP304/TP304L,TP316/TP316L, TP409/TP410) not limited

Longitudinal Finned Tube typical sizes:

|

Base Tube O.D (mm) |

Base Tube Thickness (mm) |

Fin Height (mm) |

Fin Thickness (mm) |

Fin NO.(Pc) |

|

19 mm ~76 mm |

2.0 mm ~6.0 mm |

6.0 mm ~32.0 mm |

0.8 mm ~1.2mm |

4,8,16,24,32,40,48 |

|

Base Tube Material |

Fin Material |

Tube Length (Mtr) |

||

|

Carbon Steel ,Alloy Steel ,Stainless Steel |

Carbon Steel ,Alloy Steel ,Stainless Steel |

≤ 15Mtrs |

||

Bare tube size: OD 19.05mm-OD76mm Number of fins: 2/ 4/ 8/ 16/ 18/ 32/ 36/ 40/ 48 piece per row

Longitudinal Finned Tube Competitive Advantage:

1. Longer working life than others ordinary welding helical fin tubes.

2. Much safer and energy saving.

3. Increase the heat transfer rates for viscous liquids.

4. Perforated fin type used whenever drainage of liquid from fin channels become a problem.

5. Longitudinal fin tubes are widely used in horizontal heat exchangers.

Longitudinal Finned Tube

Longitudinal Finned Tube produces by high frequency resistance welding fins in the longitudinal direction with the length of the tubes. Fin strip material shall be compatible with and suitable for standard frequency resistance welding to the specified tube material.Before applying the fins, the tube outside surface shall be properly prepared to ensure that the fin-to-tube weld is sound.The fin strip is first bend into U-shaped channel, so that each leg of the U will be a fin. The channels cut into the suitable length and oriented along the length of the tubes and resistance welded in place. The channels weld in pairs, diametrically opposed -- therefore the number of fins specified always be a multiple.

For a given pipe or tube size, the desired heat transfer surface area per unit length of tubes can be obtained by specifying the appropriate fin height and/or number of fins. The maximum number of fins depend upon the tube OD - larger OD tube can accommodate more number of fins.

Some client specify that the longitudinal finned tubes can be "cut and twisted". This operation consists of cutting through the fin channels circumference at specified intervals along the tube length. The fins are then bent (or "twisted") on one side of each cut, creating a discontinuity that promotes turbulent fluid flow, thereby enhancing heat transfer efficiency.

The choice of longitudinal finned tubes VS helical finned tubes seems to be governed mainly by geometric considerations. For example, some heater configurations consist of finned tubes inserted inside other tubes, longitudinal finned tubes are the obvious choice for such applications. In other cases, users prefer longitudinal finned tubes for installations where the tube will be oriented in a vertical direction -- the fin orientation facilitates fluid drainage on the fin side of the tube.

Like welded helical finned tubes, this welded steel configuration can be used for practically any heat transfer application, and is particularly suited to high temperature, high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

Advantages of Longitudinal Finned Tubes

Provide 8 to 12 times the heat transfer area of bare tubes.

Are more efficient than bare tubes.

Provide smaller exchangers due to increased Heat Transfer area.

Often provide a more economical selection.

Fins can be "Cut & Twist" to increase shell side fluid turbulence and improve heat transfer.

For Rapid Quotation for longitudinal finned tube, plz send requirement included:

Number of pieces

Base Tube: diameter, thickness, length and material specification

Fins: height, thickness, number, length, material specification and unfinned ends.

Delivery period required.

Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)

Key Words: Finned Tube, Fin Tubes, Embedded Fin tubes, Longitudinal Finned Tube,helical finned tubes, Fin strip