Monometallic Finned Tube

What is Monometallic finned tube?

Monometallic finned tube with fins drawn from the parent metal of the tube. All monometallic Tubes are using a cold rolling or ribbing process. Materials: Aluminium, copper, brass, cupronickel, carbon steel, stainless steel, titanium, nickel alloy, etc.

The monometallic finned tubes are formed in a cold rotary extrusion process, where continuous helical fins are radially extruded from a thick aluminium muff over a liner tube. The process of extrusion hardens the fins and prevents dissimilar metal contacts at the fin root. Compared to other products, fins do not break, unwind or become loose which affects greatly thermal efficiency.

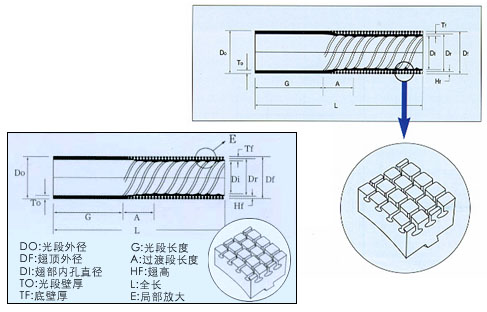

Do-----Outside diameter of plain end section

Do-----Outside diameter of plain end section

Df------Diameter of top fins

Dr------Root diameter of finned section

Di------Inside diameter of finned section

T0-----Wall thickness of plain end section光

Tf------Wall thickness of finned section

G-------Plain end length

Hf------Fin height

A-------Incomplete finned section

L-------Total length

Monometallic finned tube Applications:

Aftercoolers, air coolers, air heaters, charge air chillers, condensers, convection heaters, electric heaters, evaporators, fluid coolers, gas coolers, heat pipes, hydrogen coolers, industrial tumble dryers, intercoolers, immersion heaters, oil coolers, radiators, refrigeration, solvent recovery and steam to air heat exchangers.

Monometallic finned tube features:

1.Monometallic finned tube is a revolutionary heat transfer tube for boiling on outer surface.

2.Monometallic finned tube has very excellent heat transfer coefficient derived from an unique fine structure based on the boiling phenomenon essentially.

3.Monometallic finned tube is different from the conventional integral fin tube which simply increases the surface area.

4.By forming fine openings in the surface skin and circumferential tunnels which connect them under the surface skin, bubbles are generated continuously so that an extremely high boiling heat transfer performance can be achieved.

5.To prevent the phenomenon in which sub-cooled refrigerant invades the tunnels and re-condenses the bubble inside the tunnels, fine projections are formed just beneath the openings in the surface skin to lessen the influence of the sub-cooled refrigerant. This has improved the heat transfer performance in all regions including the low heat flux region.

6.Helix slots are added inside the tube to improve the internal heat transfer coefficient so that the overall heat transfer coefficient is more improved than normal low fin tube.

|

Monometallic Finned Tube Standard Sizes |

||||

|

Series of |

HSTE1942-1 |

HSTE1942-2 |

HSTE1942-3 |

|

|

Nominal |

Outside Diameter (Do) |

19.05 |

19.05 |

19.05 |

|

Dimensions (mm) |

Wall Thickness (To) |

1.3 |

1.5 |

1.5 |

|

Plain End Dimensions (mm) |

Outside Diameter |

15.88 |

15.88 |

19.05 |

|

Wall Thickness |

1.4 |

1.55 |

1.55 |

|

|

Finned Section Dimensions |

Number of Fins Per Inch |

42 |

42 |

42 |

|

Outside Diameter (Df) |

18.2 |

18.2 |

18.2 |

|

|

Root Diameter (Dr) |

16.8 |

16.8 |

16.8 |

|

|

Wall Thickness (Tf) |

0.65 |

0.89 |

0.89 |

|

|

Fin Height (Hf) |

0.7 |

0.7 |

0.7 |

|

|

Ridge |

Number of Ridges |

20~22 |

20~22 |

20~22 |

|

Dimensions |

Depth of Ridges |

0.4 |

0.4 |

0.4 |

|

|

Helix Angle |

30° |

30° |

30° |

|

* Gap of Fin : 0.05 ~ 0.15 Width of Tunnel: 0.3 |

||||